SECTION 6 - GENERAL MECHANICAL OVERHAUL

79

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

Camshaft timing

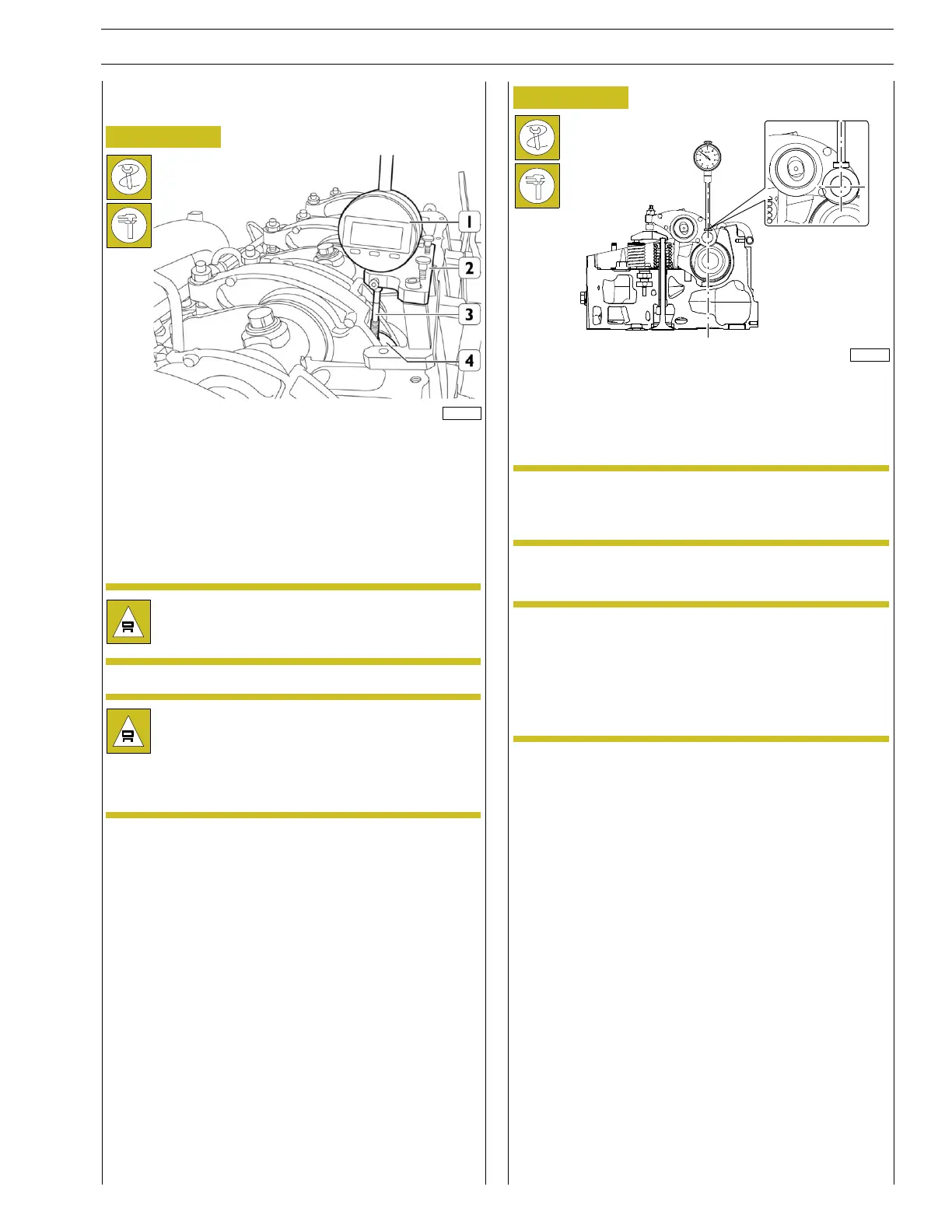

Figure 192

185253

Carefully clean the surface of the head on which the rocker

arm cover rests.

Using the magnetic support 99370400 (2), as shown in the fi-

gure, arrange the dial gauge (0-30mm) 99395606 (1) with the-

flatbasedrod(3)positionedontherockerarmroller(4)which

controls the exhaust valves of cylinder no. 3 and preload to at

least 7 mm.

Position the flat based dial gauge so that its axis pas-

ses through the centre of the roller on which it is

resting.

During the CHECK phase, not during the engine

overhaul phase, the allowed tolerance of the mea-

surement is between -0.05 - +0.12 mm.

The allowed measurement tolerance during

OVERHAUL is ± 0.05 mm.

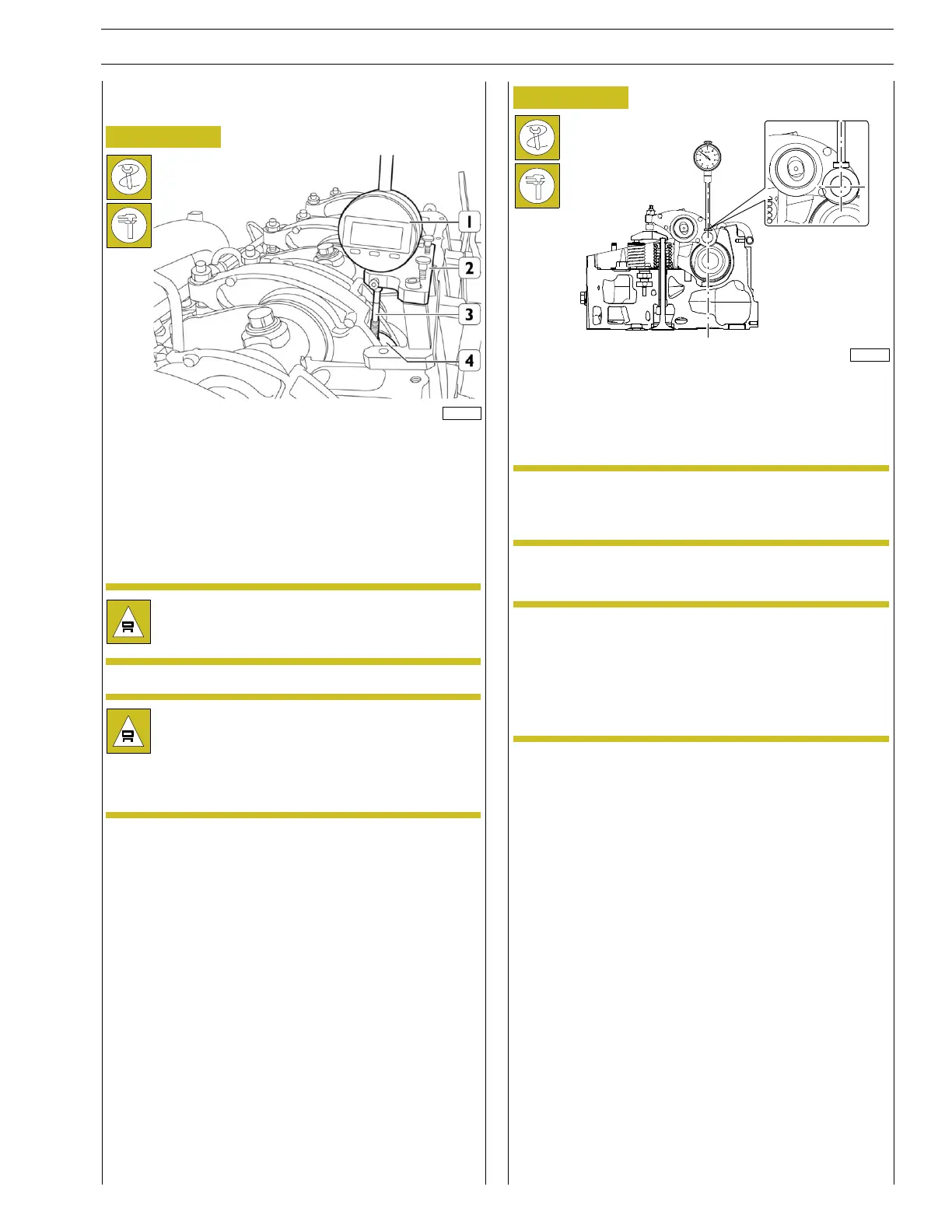

Figure 193

177714

Using the specific tool to turn the engine flywheel 99360321,

turn the crankshaft in the opposite direction to that of opera-

tion until the pointer of the dial gauge reaches the minimum

value beyond which it can no longer fall.

NOTE The measurement must be taken holding the

rocker roller in contact with the profile of the

exhaust cam of the camshaft.

reset the dial gauge

NOTE The dial gauge is to be zeroed with the rocker arm

roller in contact with the base radius of the cam

profile .

This occurs when the flywheel is turned in the op-

posite direction of the operating direction approx.

1 and 1/4 rotations.

Loading...

Loading...