86

SECTION 6 - GENERAL MECHANICAL OVERHAUL

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

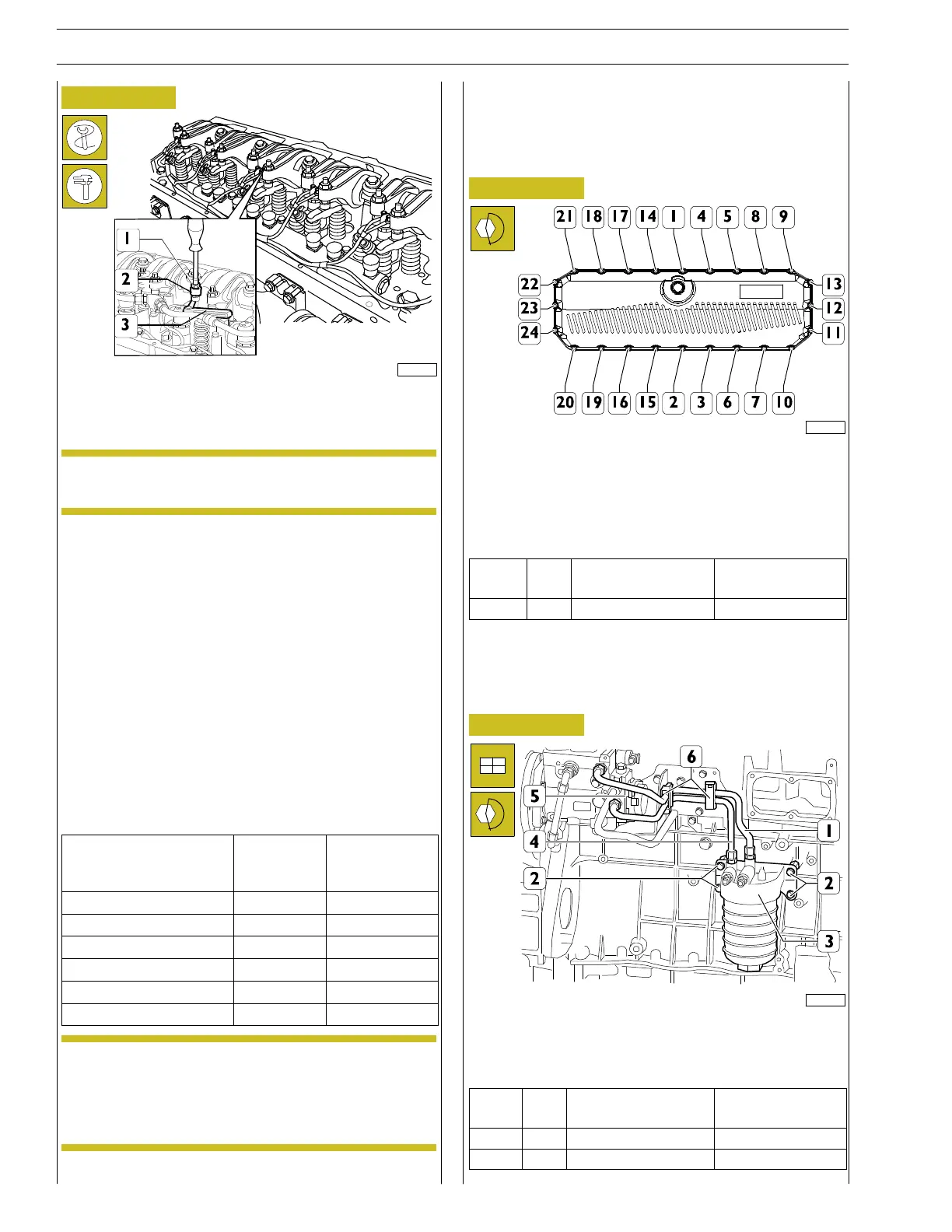

Figure 206

114287

Take the cylinder whose clearance has to be adjusted into the

combustion phase; the valves of this cylinder are closed while

they balance the symmetric cylinder valves.

NOTE Thecorrespondenceofthe symmetrical cylin-

dersis1-6,2-5and3-4.

In order to carry out these operations correctly, follow the indi-

cations below in accordance with the indications in the table.

Using a box wrench, loosen the nut (1) locking the adjustment

screw.

Insert the feeler gauge blade (3) corresponding to the operating

clearance indicated in the table “Data and assembly clearance”

in SECTION 7 - Technical specifications.

Use a suitable wrench to screw or unscrew rocker arm (2) adju-

sting screw.

Check that the blade of the feeler gauge (3) can slide with a light

amount of friction.

Lock the nut (1) holding the adjustment screw still.

To carry out the adjustments stated above, the sequence shown

in the table is mandatory.

FIRING ORDER 1-4-2-6-3-5

Start and rotation in

theenginedirection

Balancing

cylinder

valves no.

Adjust valve

clearance for

cylinder no.

1and6atT.D.C. 6 1

120 degree of angle [˚] 3 4

120 degree of angle [˚] 5 2

120 degree of angle [˚] 1 6

120 degree of angle [˚] 4 3

120 degree of angle [˚] 2 5

NOTE Check during each rotation phase, the accuracy

of the position by using the specific pin and

inserting it into the hole marked with a notch on

the flywheel corresponding to the position of

the pistons.

ASSEMBLY OF ENGINE AT BENCH

(COMPONENTS AT THE TOP PART 3)

Tappet cover assembly

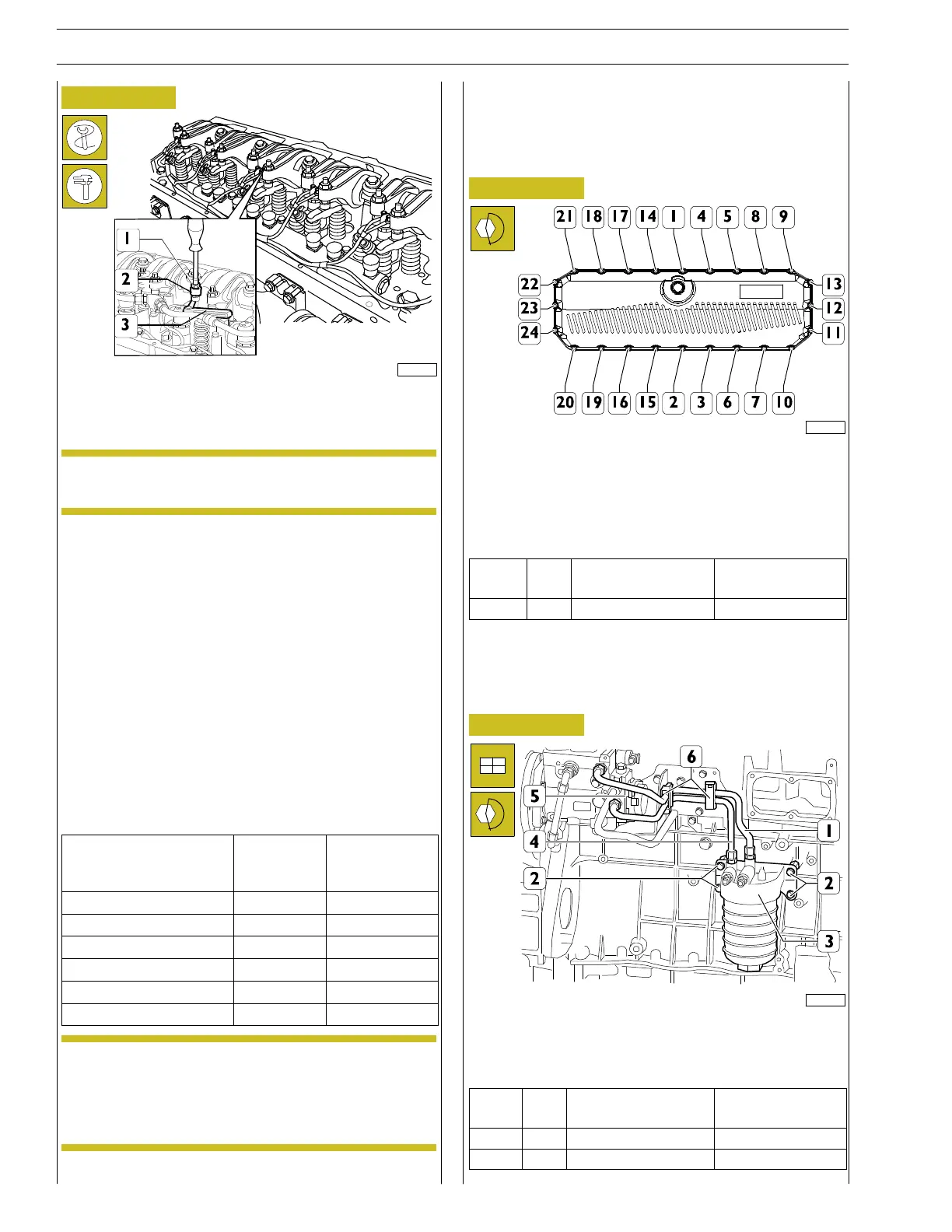

Figure 207

221122

Position the cover and insert all the screws.

Replace the screws in the sequence 1-10-20-21-9 and then in

the sequence shown in the figure until contact.

Tighten the screws 1-24 in the sequence shown to the prescri-

bed torque.

Ref.

No. Description

Tightening

torques

(1 - 24) 24 Screws M6x1 8.5 ±1.5 Nm

ASSEMBLY OF ENGINE AT BENCH

(COMPONENTS AT THE INTAKE SIDE)

Fuel filter assembly

Figure 208

225014

Position the fuel filter together with the support (3), tighten the

screws (2) to the prescribed torque, connect the fuel inlet (4)

and outlet (1) pipes onto the filter support

Ref.

No. Description

Tightening

torques

(2) 4 M8x1.25 24.5 ± 2.5Nm

(1,4) 2 Fittings M18x1.5 37 ± 3Nm

Loading...

Loading...