SECTION 4 - SCHEDULED MAINTENANCE

9

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

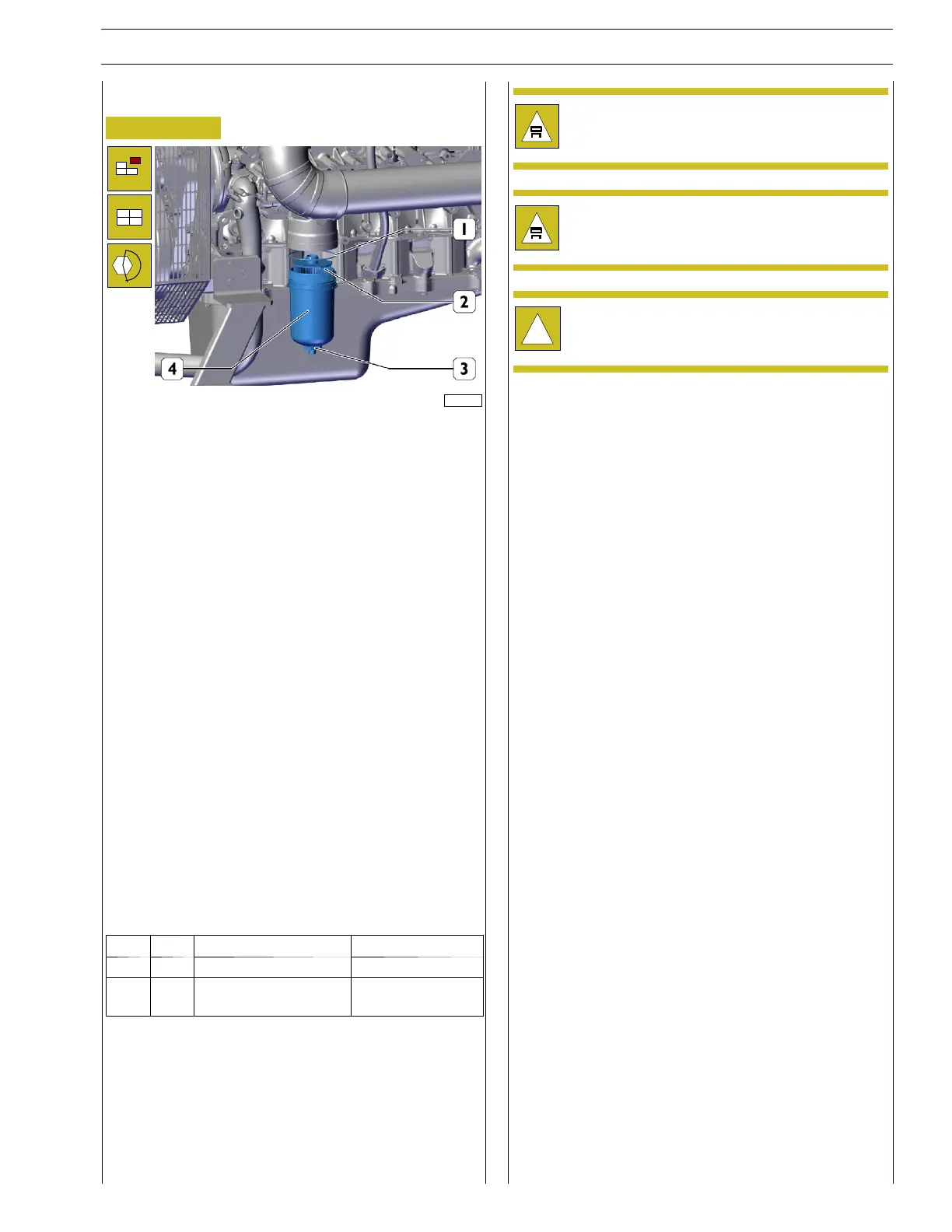

Change lubricant oil filter

Figure 7

227780

Only use filters with the following specifications:

- degree of filtering < 12m.

- filtering efficiency ß > 200 (99.5%).

Only proceed when the engine is not turning and is at low

temperature so as not to run the risk of burns.

- Proceed with draining the spent lubricant oil (see para-

graph ENGINE LUBRICANT OIL REPLACEMENT).

- Place a suitable container for collecting the spent oil un-

der the oil filter next to the drain plug (3).

- Remove the filter (4) by unscrewing it.

- Replace the filter element (2) and the O-ring seal (1) con-

tained inside the filter (4).

- Clean the surface carefully.

- Moisten the O-ring seal (1) of the new filter with oil.

- Tighten the drain plug (3) and the filter body (4) to the

torque indicated in the table.

- Proceed with the refilling operation of the lubricant oil

(see paragraph ENGINE LUBRICANT OIL REPLACE-

MENT).

Operate the engine for a few minutes and then check the

level using the dipstick.

If necessary, top up to compensate for the quantity of oil used

to fill up the filtering cartridge.

Ref.

No. Description Torque

4 1 Engine oil filter 60 ± 5 Nm

3 1

Drainplugonengine

oil filter

6.5 ± 1.5 Nm

After changing the engine lubricant oil make sure

that the level does not exceed the ”Max” limit on

the oil level dipstick.

Make sure that the dipstick is fully inserted and

that the filler plug is tightened fully in the clockwise

direction.

!

Dispose of consumable materials and the parts in

contact with them (for example filters) in accor-

dance with the law.

Loading...

Loading...