52

SECTION 6 - GENERAL MECHANICAL OVERHAUL

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

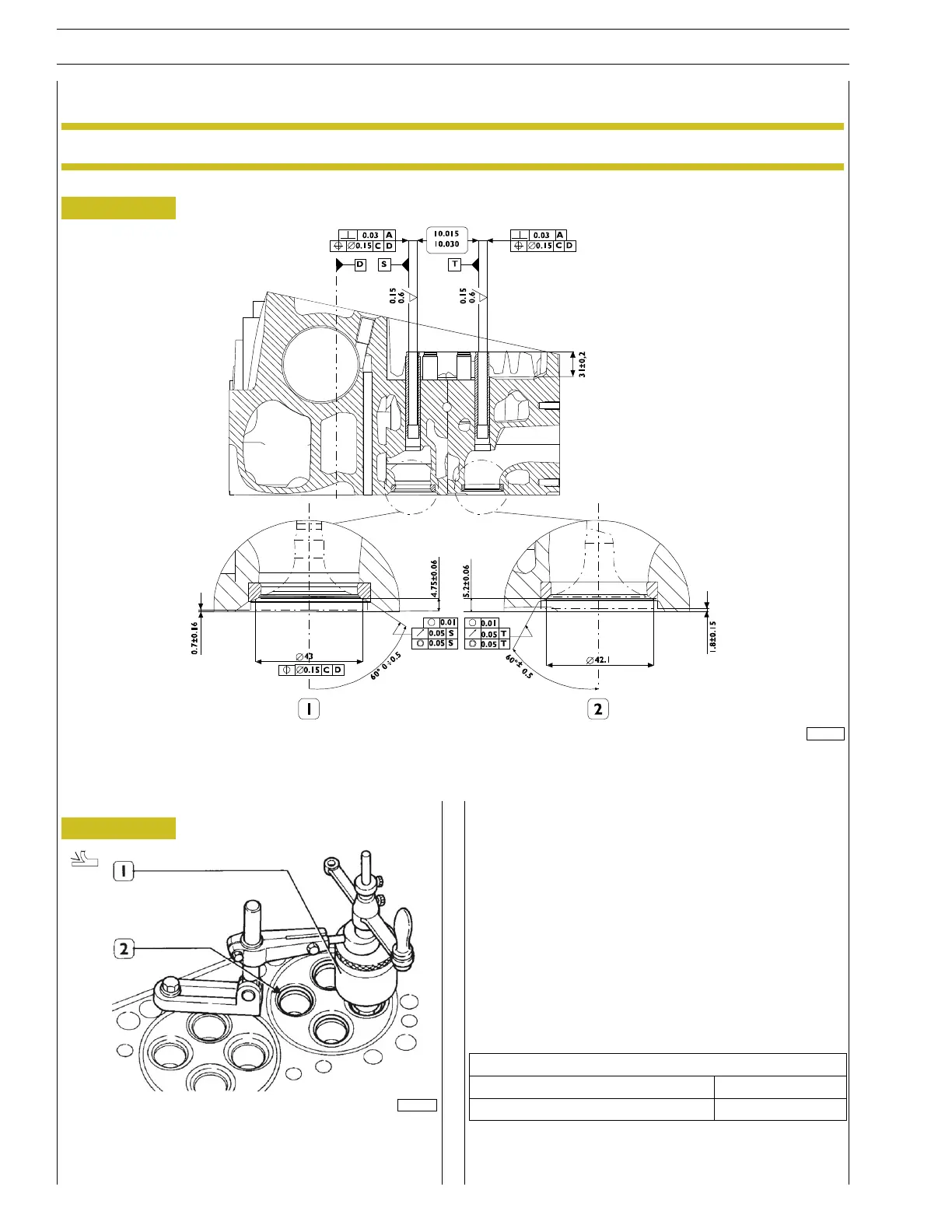

Regrinding - replacing the valve seats

NOTE The valve seats are reground whenever the valves or the valve guides are ground and replaced.

Figure 115

181831

1 Intake valve seat 2 Exhaust valve seat

When replacing/checking the valve seats, refer to the main data provided in the figure.

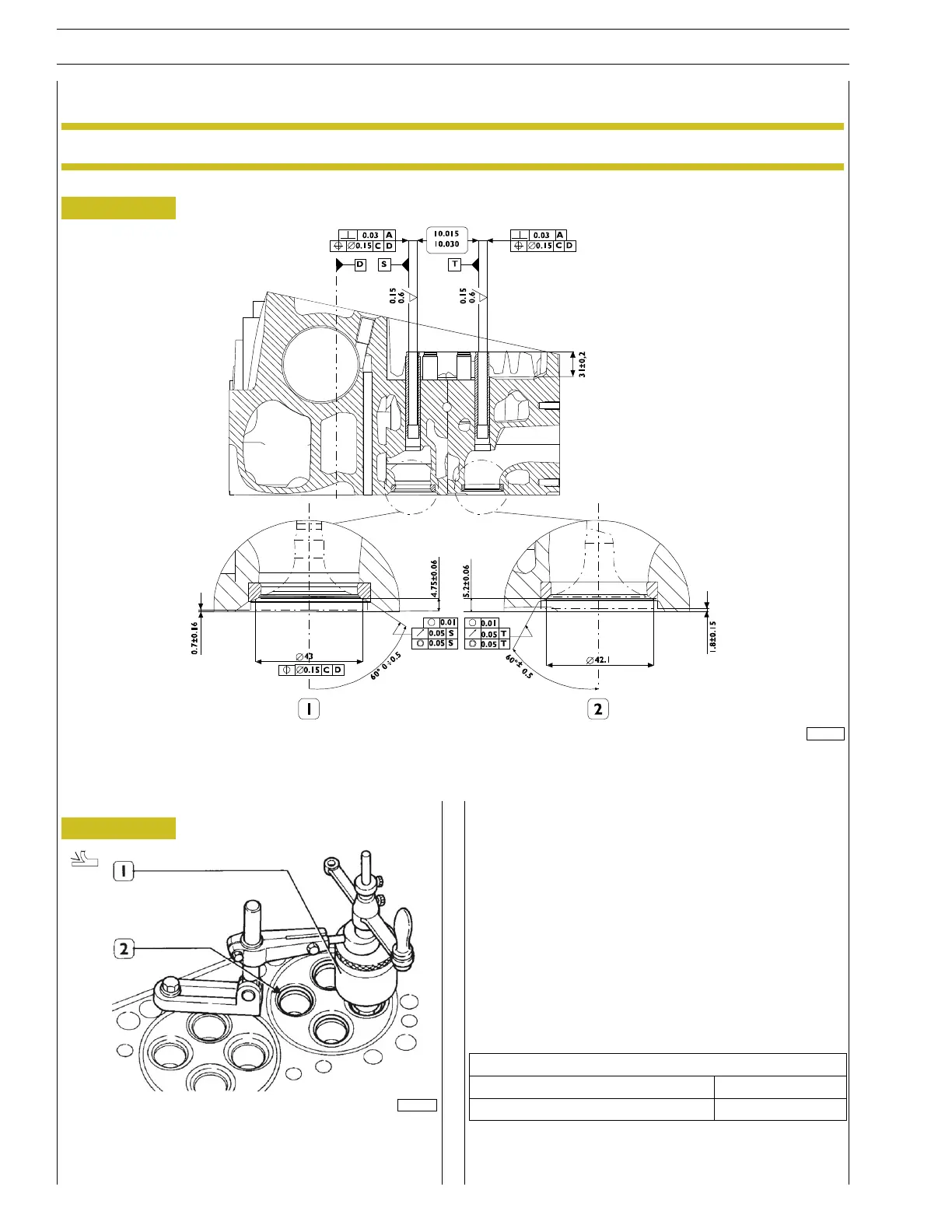

Figure 116

41032

Check the valve seats (2). If there are light scorings or burnings,

regrind them with a suitable tool (1) according to angles

shown in the previous figure.

If they need to be replaced, using the same tool and taking care

not to accidentally damage the cylinder head, remove as much

material as possible from the valve seats until it is possible to

extract them from the cylinder head using a punch .

Heat the cylinder head to 80 - 100 ºC and, using a drift, fit in

the new valve seats (2), chilled beforehand in liquid nitrogen.

Using the tool (1), regrind the valve seats according to the

angles shown in the previous figure .

After regrinding the valve seats and using a dial gauge (0-5mm)

99395603 with base 99370415, check that the position of the

valves in relation to the cylinder head surface respects the

values shown below:

Technical data

Intake valves recessing -0.54 - -0.86 mm

Exhaust valves recessing -1.47÷-1.79mm

Loading...

Loading...