48

SECTION 6 - GENERAL MECHANICAL OVERHAUL

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

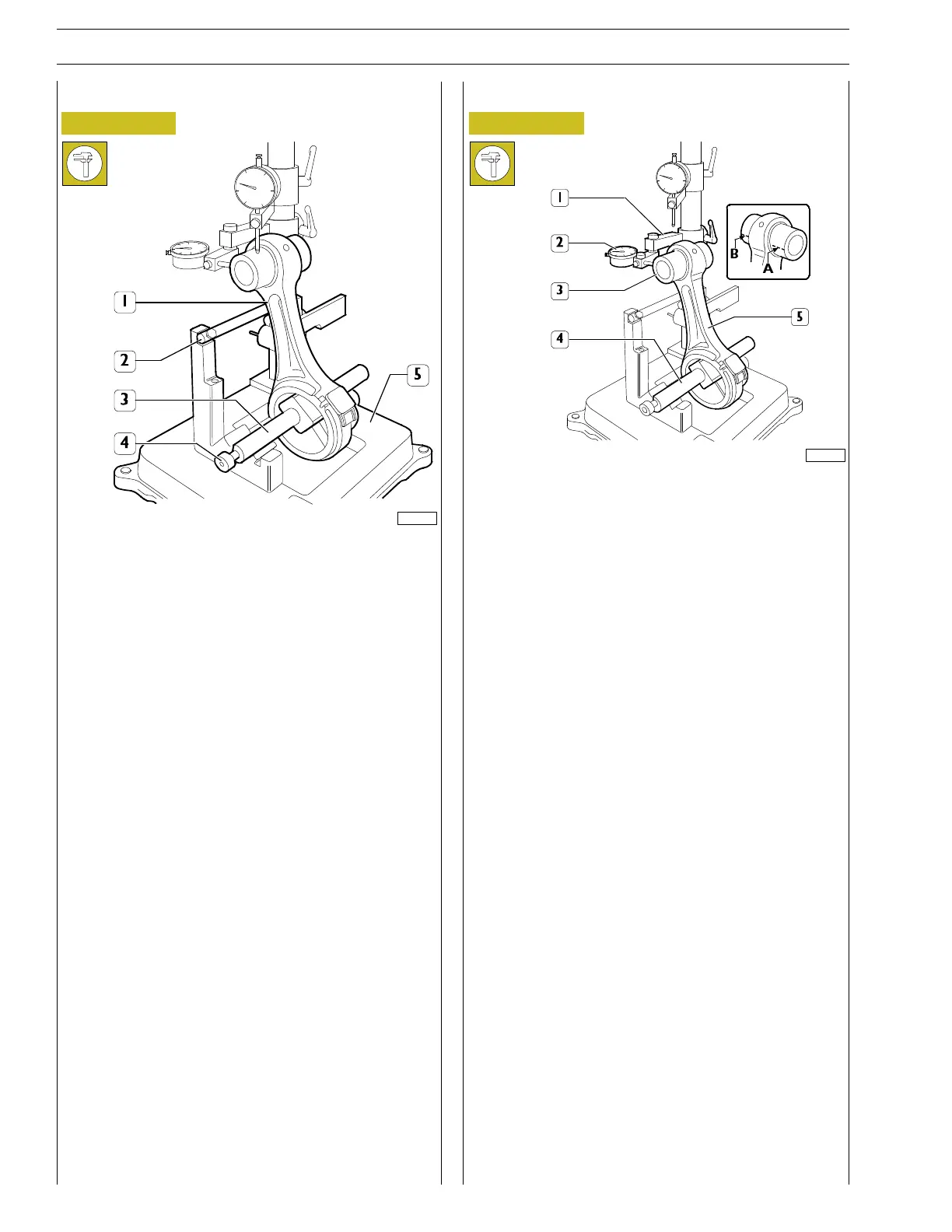

Axis alignment check

Figure 104

61696

Check the connecting rods axes for parallelism (1) using a

suitable device (5) and proceeding as follows.

Fit the connecting rod (1) on the spindle of the tool (5) and

lock it with the screw (4).

Set the spindle on the on the V prisms resting the connecting

rod 1 on the stop bar (2).

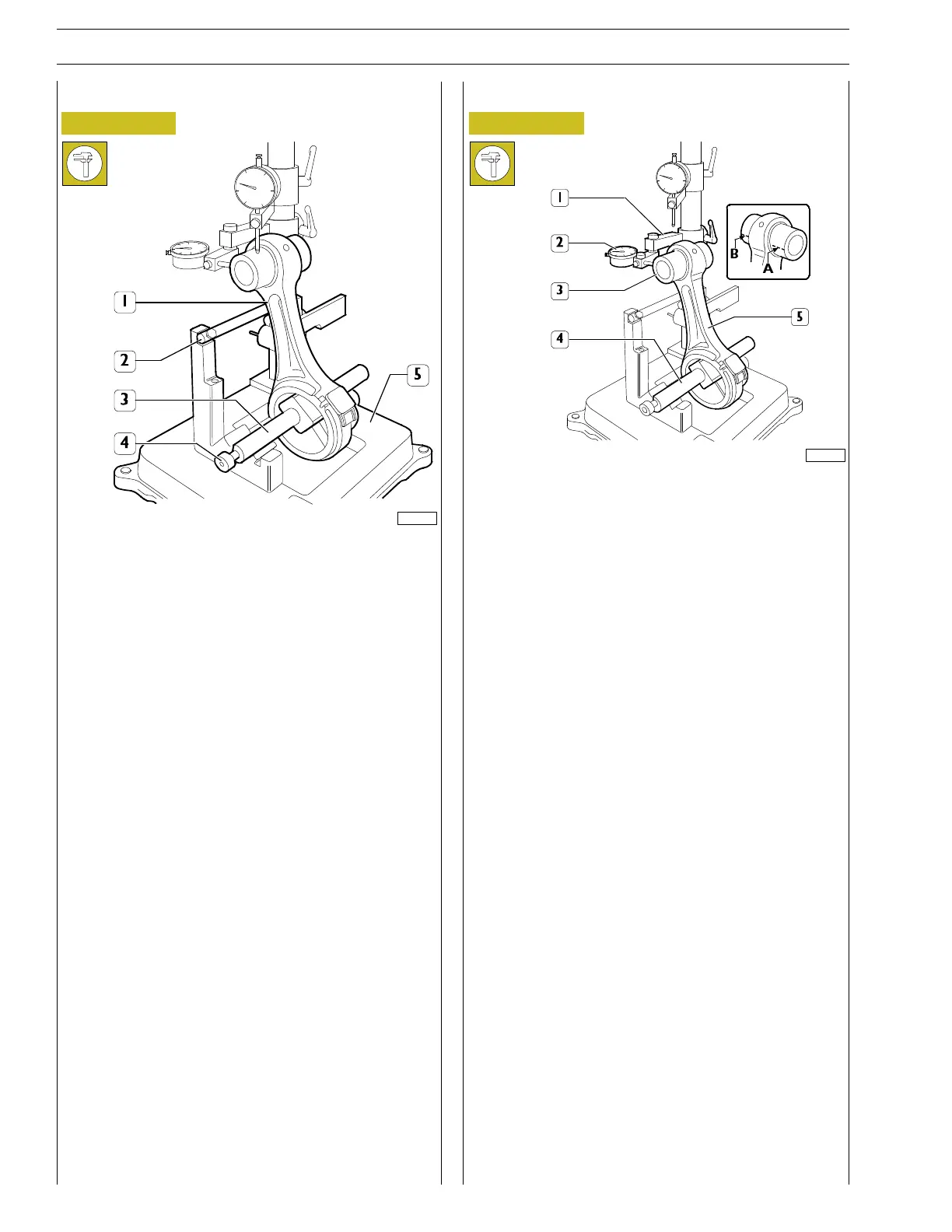

Torsion check

Figure 105

61694

Check the torsion of the connecting rod (5) by comparing two

points (A and B) of the pin (3) on the horizontal plane of the

axis of the connecting rod.

Position the mount (1) of the dial gauge (2) so that this

pre-loads by approx. 0.5 mm on the pin (3) at point A and zero

the dial gauge (2). Move the spindle (4) with the connecting

rod (5) and compare any deviation on the opposite side B of

the pin (3): the difference between A and B must be no

greater than 0.08 mm.

Loading...

Loading...