SECTION 6 - GENERAL MECHANICAL OVERHAUL

53

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

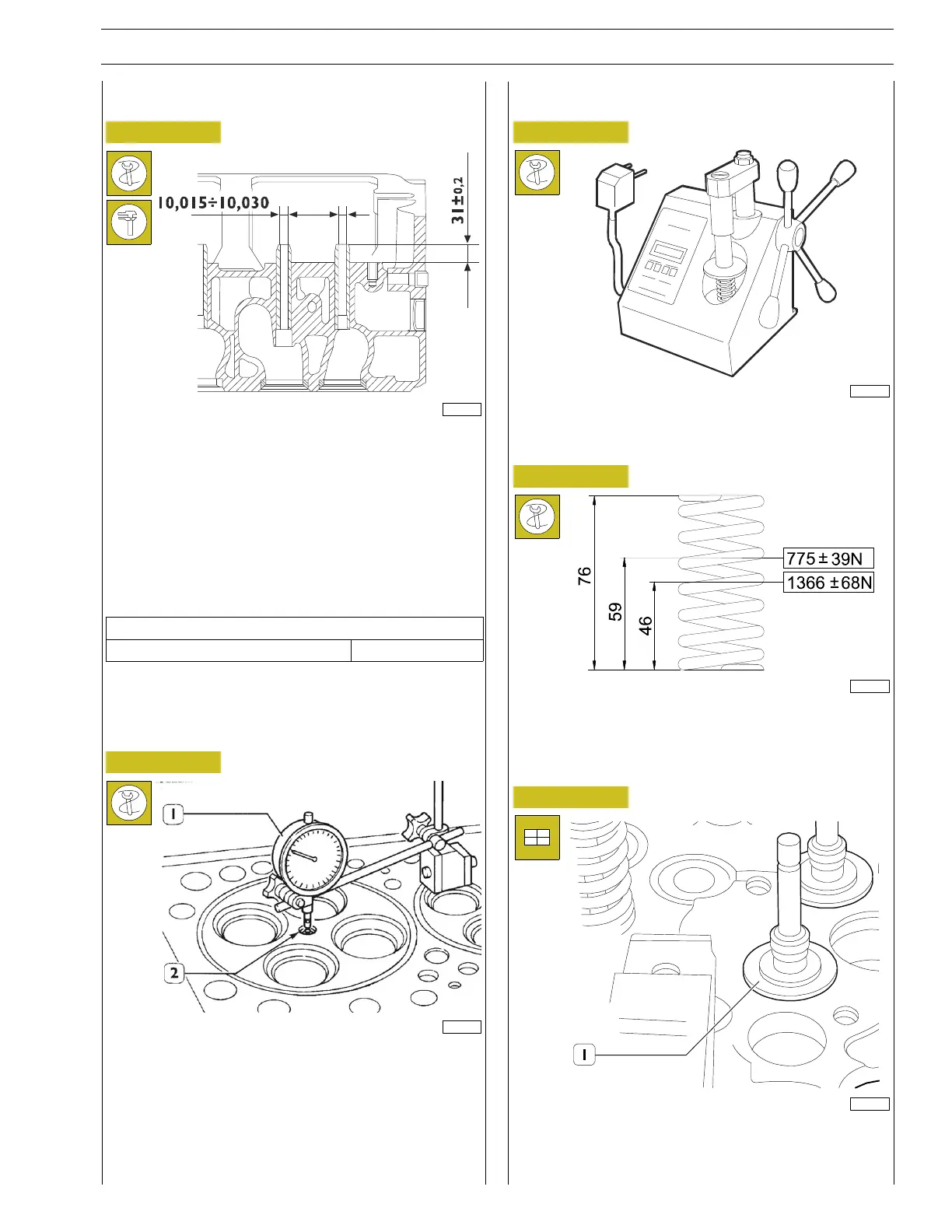

Replacing the valve guides

Figure 117

163815

* = Measurement to be obtained after driving in the valve

guides

The valve guides are removed with the drift 99360143.

Assembly is carried out with the drift 99360296 equipped with

tool 99360143.

It determines the exact position of the valve guides fitted in

the cylinder head; if they are not available, you need to drive

the valve guides into the cylinder head so they protrude by a

value equal to the one given below .

Technical data

Valve guide standout 30.80 - 31.2 mm

After driving in the valve guides, smooth their holes with

sleeker 99390330.

Checking protrusion of injectors

Figure 118

47585

Check injector protrusion (2) using a dial gauge (1).

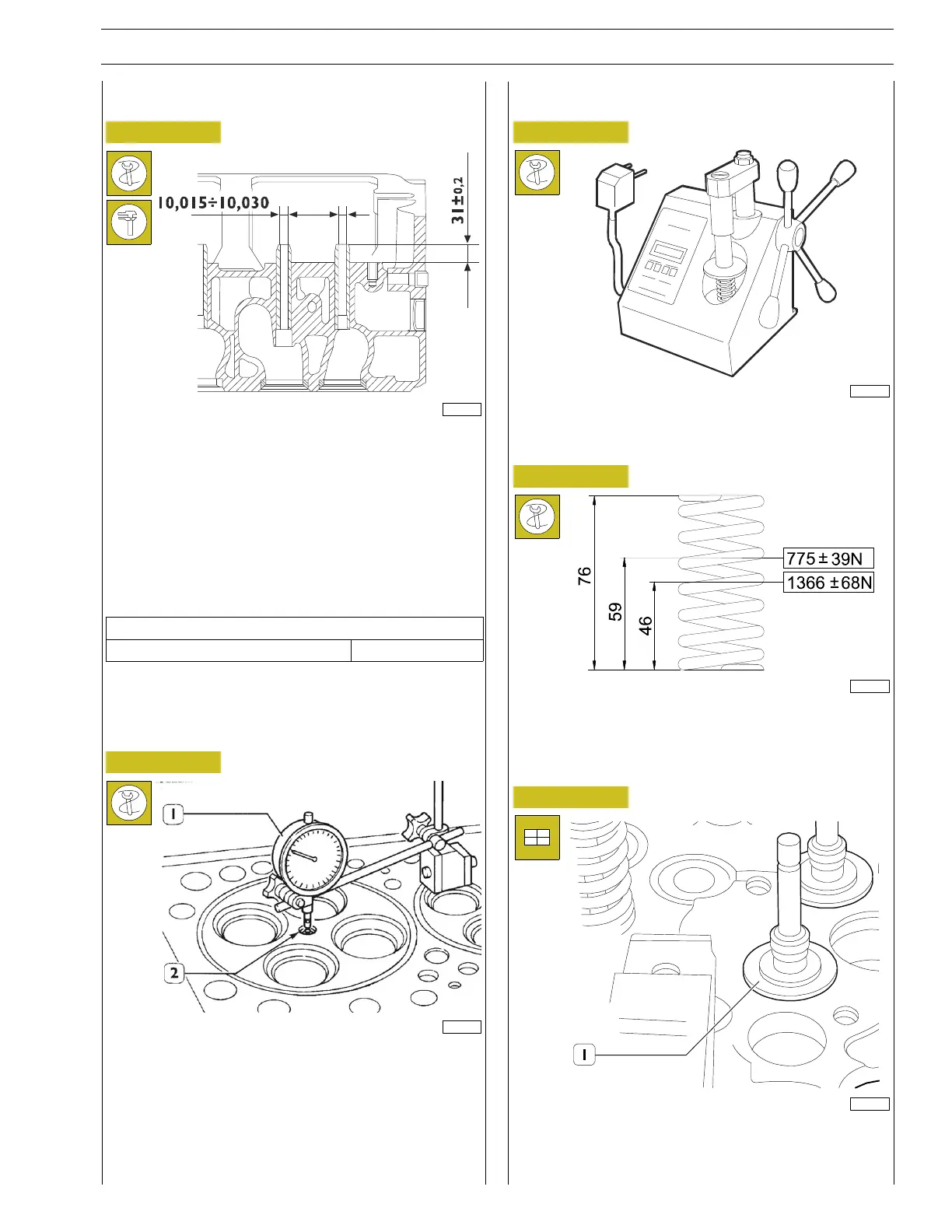

Valve spring check

Figure 119

70000

Before fitting, the flexibility of the valve springs has to be

checked using a suitable device.

Figure 120

108842

Compare the load and elastic deformation data with that of

the new springs indicated in the figure.

Valve assembly

Figure 121

193982

Lubricate the valve stem and insert the valves in the respective

valve guides; fit the lower plates (1).

Loading...

Loading...