6

SECTION 4 - SCHEDULED MAINTENANCE

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

Engine visual inspection

Perform a thorough check before start-up in order to obtain

maximum engine duration.

Check for any leaks (oil, coolant and fuel), broken or weake-

ned pipes, loose clips and bolts, worn belt, wiring (loose con-

nections, worn or frayed cables) and a build-up of dirt; in the

event of any problems, perform the operations necessary to

restore the engine.

Any spilt fluid must be removed for all types of

leak (coolant, oil or fuel).

If a leak is discovered then find its source and carry

out the necessary repair.

!

A build-up of oil or grease on the engine repre-

sents a fire risk.

Clean the cock tap (1) before performing the

operation so as to minimize the risk of contamina-

ting the system.

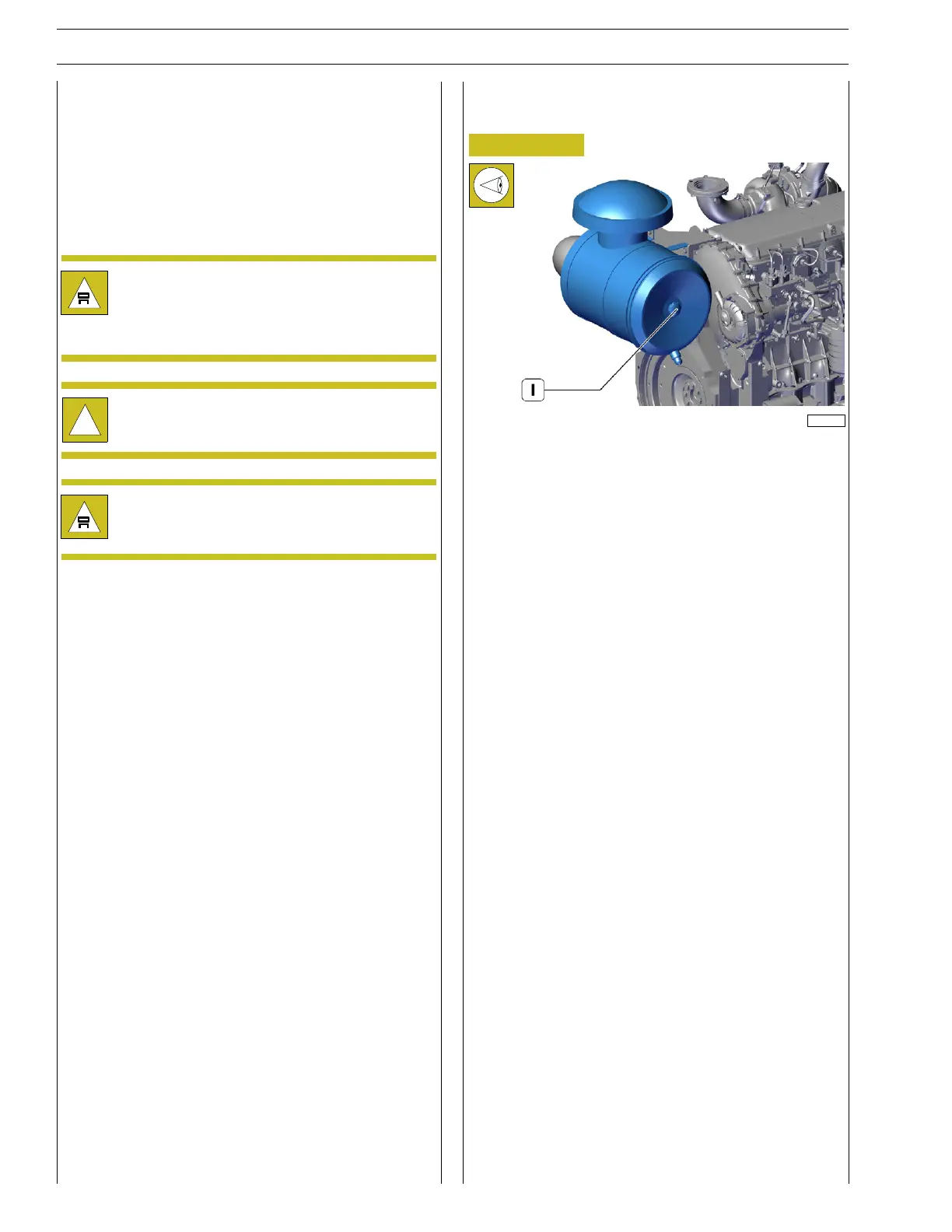

Inspection cleaning of the air filter and relative

seat

Figure 2

227777

Proceed only wiith engine off:

Remove the air filter (1).

Remove the filter cartridge .

Make sure there are no impurities. Otherwise, clean the filter

element according to the instructions provided below.

Blow dehumidified compressed air on the filtering element,

working from the inside outward (maximum pressure

200 kPa).

Do not use cleaners; do not use diesel oil.

Never strike the filter element with tools and check its condi-

tion before refitting it.

Replace it if broken or torn.

Check the condition of the gasket at its base.

Mount following the steps for removal in the reverse order.

Loading...

Loading...