SECTION 4 - SCHEDULED MAINTENANCE

3

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

SCHEDULED MAINTENANCE

Introduction

To ensure best operating conditions, on the following pages are indicated the checks, tests and adjustmen ts which shall be carried

out on the different parts at the established time.

The frequenc ies of the maintenance operations are indicative since t he engine use and its characteristics are essential to evaluate

replacements and checks.

Not only it is permitted, but we also suggest that the staff in charge of maintenance should also perform those checking and main-

tenance operations which do not fall among those listed below, but are recommended by good-practices and particular conditions

of use of the engine.

Furthermore, in case of clear malfunctioning of the engine, for example excessive grade of smoke of exhaust gases, high tempera-

ture of the coolant or low oil pressure, prompt measures must be taken to verify the causes of the defect.

Operators are also reminded that any maintenanc e operation, even the easiest one, is to be performed in compliance with acci-

dent-prevention laws for the s afety of the staff in charge of maintenance.

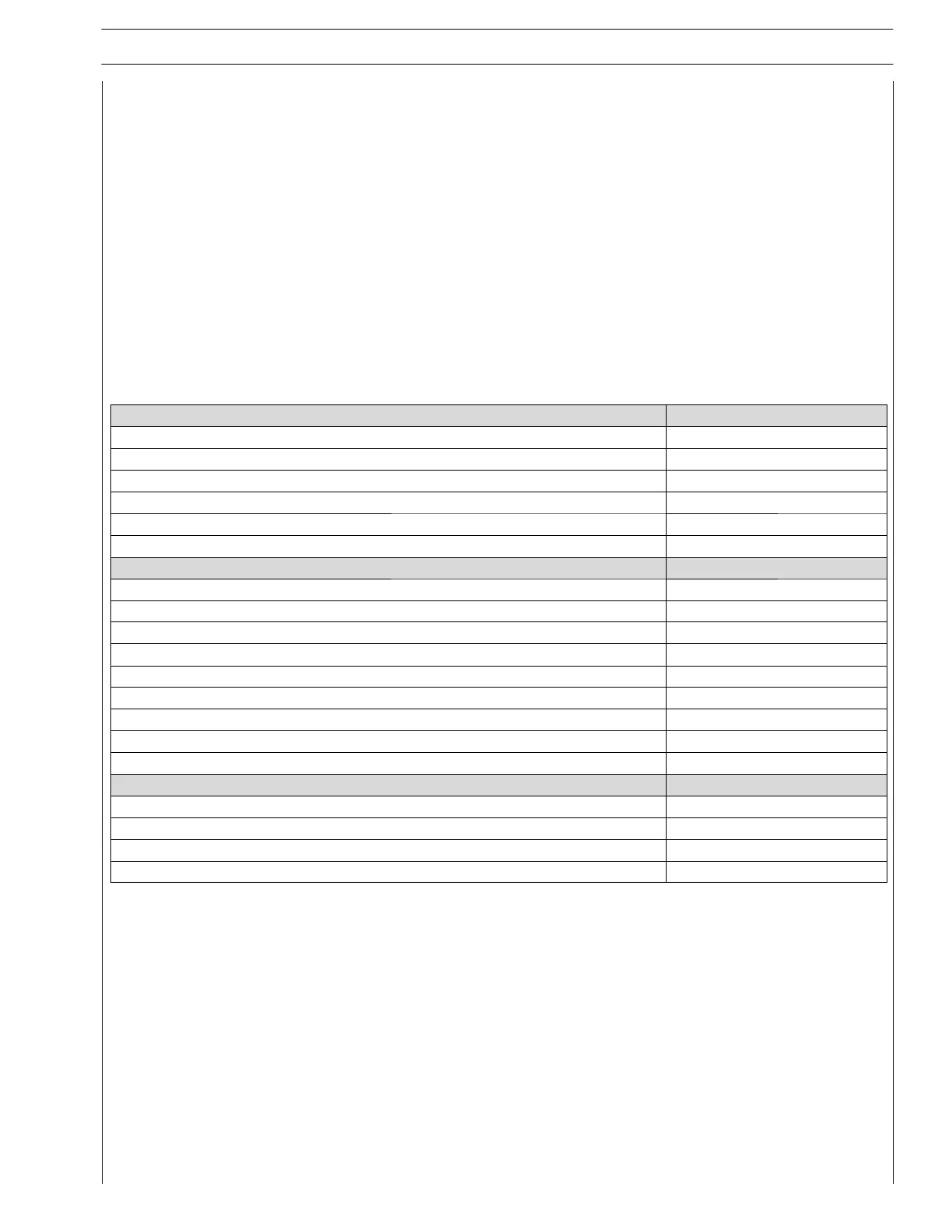

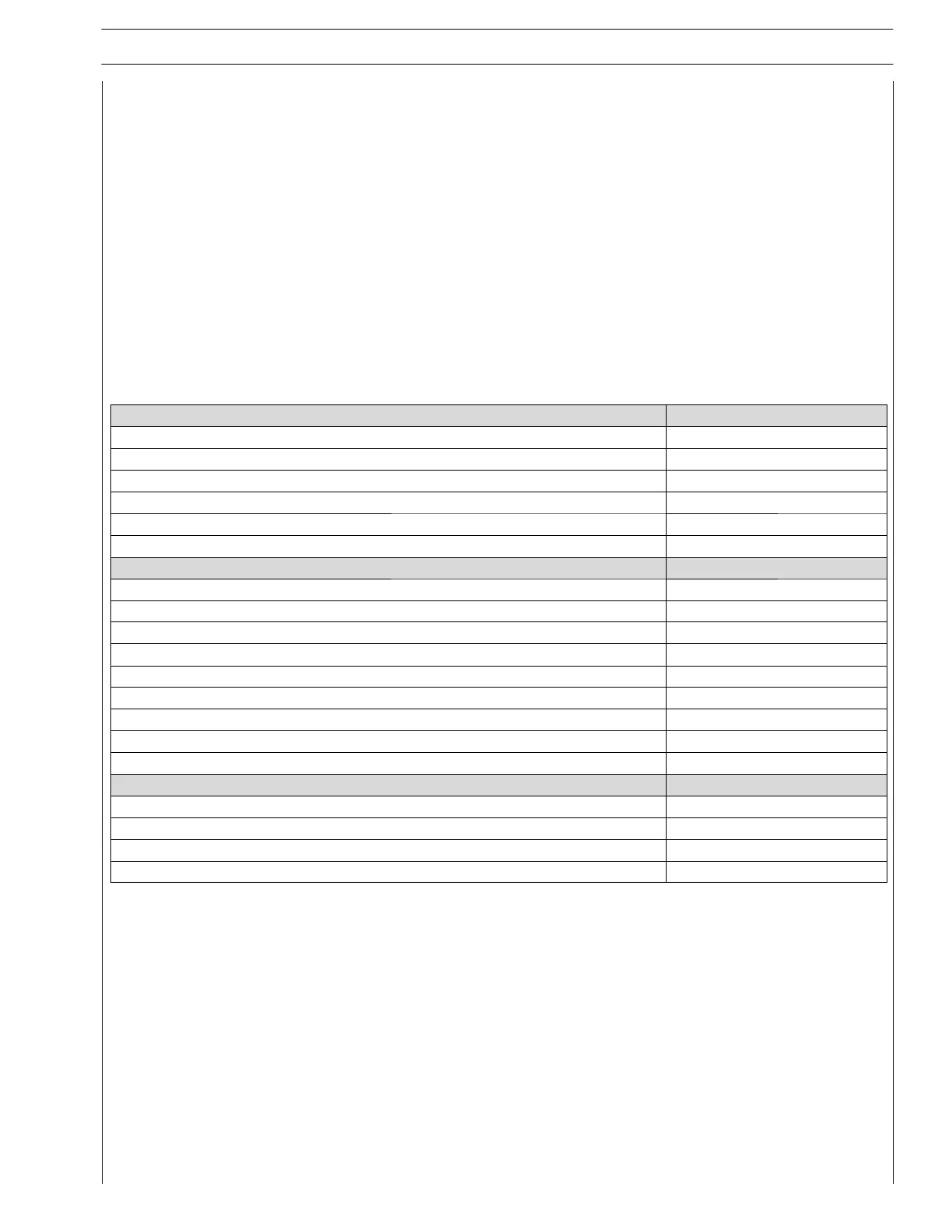

Checks and scheduled maintenance procedures

Checks to be made during periods of use Frequency

Check th e engine lubricant oil level daily

Check engine coolant level daily

Engine visual inspection 50 hours / 15 days

Inspection cleaning of the air filter and relative seat 1monthly

Check tension and con dition of anc illary belt 300 hours / 6 months

Exhaust gas pipes(s) condition check 6months

Periodical maintenance Frequency

Draining the water from the fuel prefilter (if any) 150 hours / 6 months

Condensed water drainage from fuel tank 150 hours / 6 months

Change engine lu bricant oil 600 hours/1 year

(2) (3)

Change lubricant oil filter 600 hours/1 year

(2) (3) (4)

Replace fuel prefilter (if fitted) 600 hours/1 year

Replacing fuel filter 600 hours/1 year

(1) (2) (3)

Change air filter 1200 hours / 2 years

Replace auxiliary member drive belt 1200 hours / 3 years

Replacing blow-by filter element 1800 hours/1 year

Unscheduled maintenance: Frequency

Visual turbocharger in spection 1200 hours / 2 years

Clean the heat exchanger (radiator) 1200 hours / 2 years

Check the tappet clearances and adjusting if necessary 2,400 hours

Replaceenginecoolant 3000 hours / 2 years

(5)

1) Maximum period relating to the us e of high quality fuel, (specification ASTM D975 or EN 590); w hich is reduced in the event

of fuel co ntamination and alarm signals caused by filter clogging and/or the presence of water in the prefilter. The filter clogging

signal indicates th at the filter must be replaced. If the warning light of water present in the prefilter does not go off after drai-

nage, then the prefilter must be replaced.

2) To be performed every year even if the specified operating hours interval has not been reached.

3) Frequencies are valid for lubricant oils which comply with the international specifications as in dicated in Section 1 - General

table ”General Characteristics”.

4) Only use filters with the following specifications:

- degree of filtering < 12 m

- filtering efficiency 99.5% (ß > 200).

5) To be performed every two years even if the specified operating hours interval has not been reached.

Loading...

Loading...