92

SECTION 6 - GENERAL MECHANICAL OVERHAUL

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

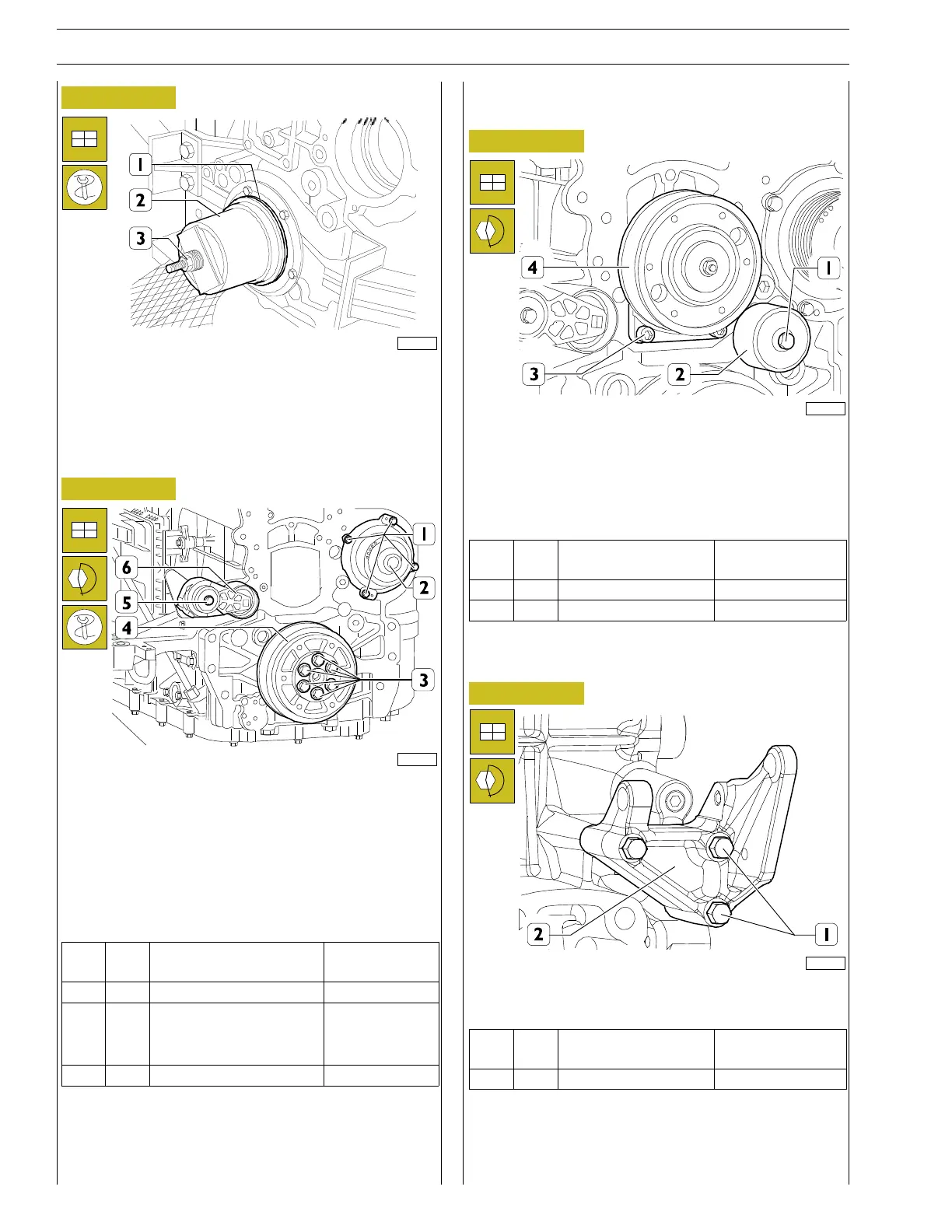

Figure 228

60564

Position the sealing gasket (1) onto the crankshaft, fit the keying

device 99346250 (2) and while tightening the nut of the tool

(3) drive in the sealing gasket (1).

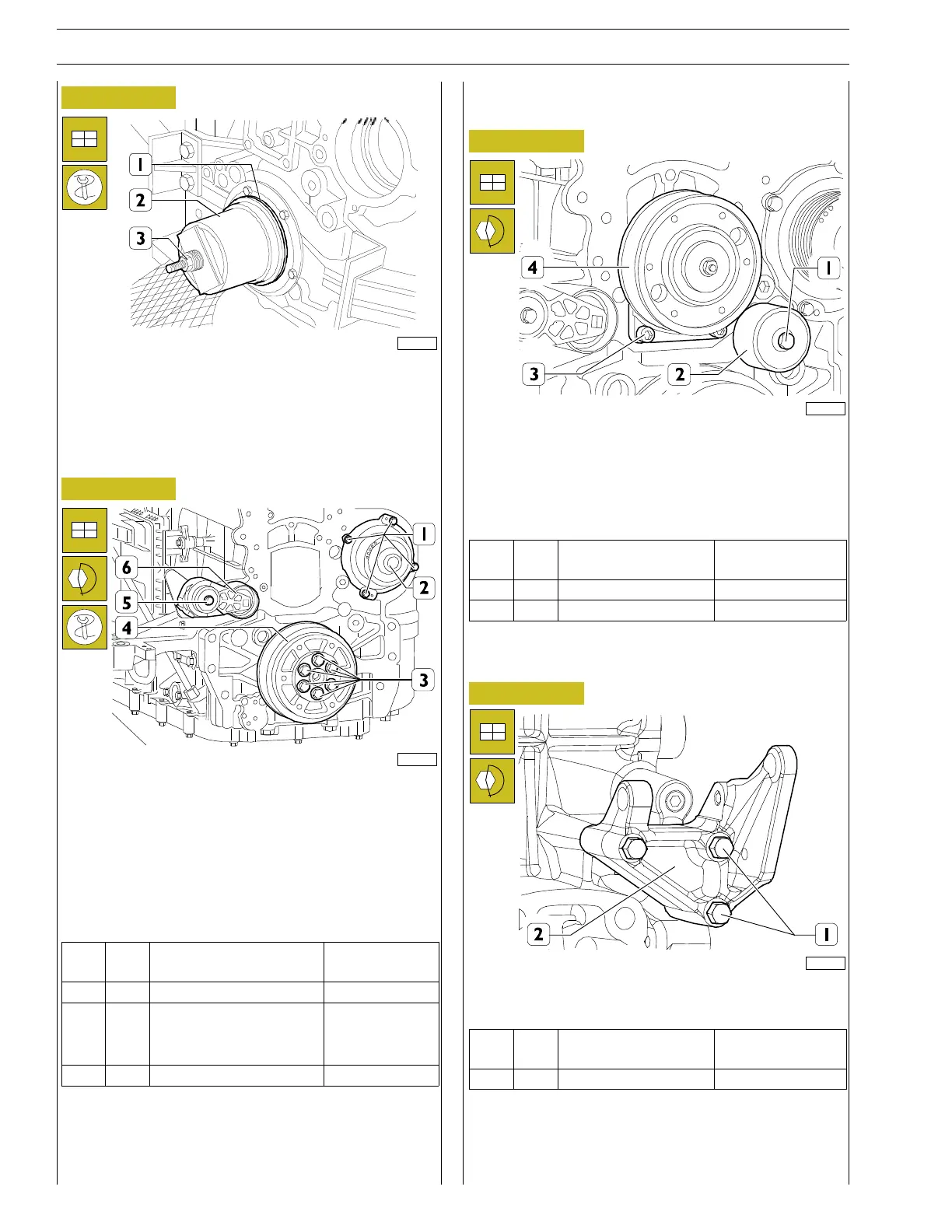

Assembly of auxiliary parts

Figure 229

225016

Block rotation of the flywheel with the tool 9936035I.

Mount the automatic belt tensioner (6) and the nuts (5) to the

torque indicated in the table.

Fit the crankshaft pulley (4) and tighten the screws (3) to the

torque indicated in the table.

Fit the water pump (2) together with the new gasket and

tighten the screws (1) to the torque indicated in the table.

Ref.

No. Description

Tightening

torques

(1) 4 Screws M8 X 1.25 X 20 25 ± 2.5 Nm

(3) 6

M14 x 2 screws

Step 1 70 Nm

Step 2 50˚

(5) 1 M10x1.5screw 45 ± 5 Nm

Electromagnetic coupling assembly

Figure 230

225023

Fit the pulley electromagnetic coupling assembly (4) and

tighten the screws of the plate (3) to the torque indicated in

the table.

Mount the fixed belt tensioner (2) and the nuts (1) to the

torque indicated in the table.

Ref.

No. Description

Tightening

torques

(1) 1 Screws M12 X 1.75 105 ± 5 Nm

(3) 5 Screws M12 X 1.75 100 ± 5 Nm

Alternator support assembly

Figure 231

224063

Fit the alternator support (2) and tighten the screws (1) to the

torque indicated in the table.

Ref.

No. Description

Tightening

torques

(1) 3 M10x1.5screws 44 ± 4 Nm

Loading...

Loading...