SECTION 6 - GENERAL MECHANICAL OVERHAUL

83

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

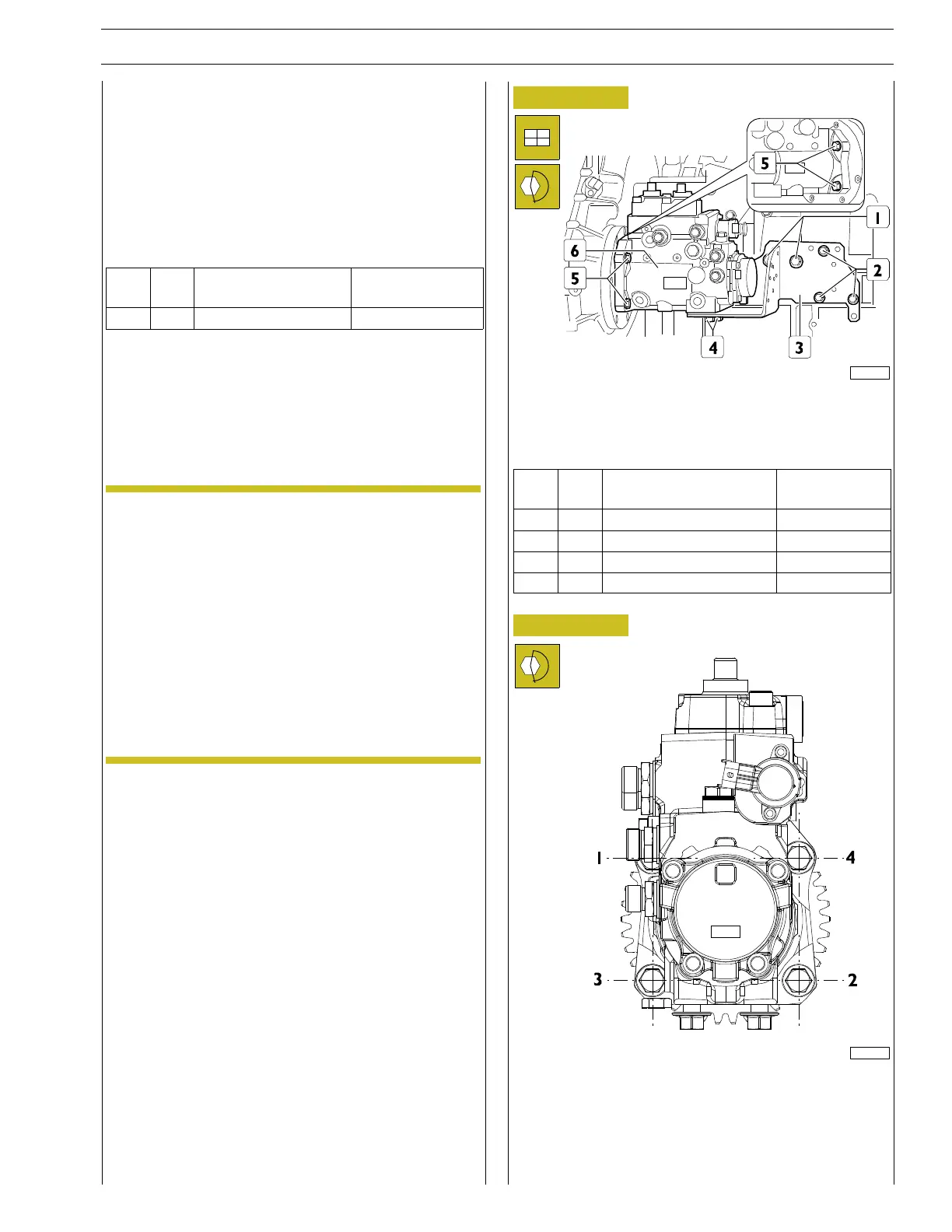

Fit tool 99360612 (5) into the flywheel sensor seat (6).

Through the timing sensor, insert the tool for phonic disc ti-

ming on the camshaft 99360613 (2) on the tooth (")recove-

red from the phonic wheel.

If the tool (2) is difficult to fit, loosen the screws (3) and direct

the phonic wheel (1) properly so as to position the tool (2)

on the tooth correctly.

Tighten the screws (3).

Ref.

No. Description

Tightening

torques

(3) 4 M8X1.25 screws 24.5 ± 2.5 Nm

Remove tools 99360612 and 99360613.

ASSEMBLY OF ENGINE AT BENCH

(COMPONENTS AT THE INTAKE SIDE)

High pressure pump assembly

Bring the flywheel to 36˚ before TDC of the first cylinder.

NOTE This position can be obtained by turning the en-

gine flywheel in the opposite direction to the

operating direction in the 30˚ position marked

by THREE notches (4) and continuing to turn

the flywheel in the same direction until reaching

thenexthole(by6˚).

If the engine flywheel does not have 3 notches,

to identify the reference hole simply: turn the

flywheel in the opposite direction to the opera-

ting direction until reaching the position marked

with 2 notches (54˚ before cyl. 1 T.D.C.); conti-

nue rotating in the engine operating direction

for 3 holes (remember that each hole corre-

sponds to a flywheel rotation of 6˚).

Insert the specific tool 99360612 through the seat of the fly-

wheel sensor into the corresponding hole on the flywheel.

Figure 200

221104

Position the bracket (3) and tighten the screws (1,2).

Position the high pressure pump (6) and tighten the screws (4,

5) to torque shown in the table.

Ref.

No. Description

Tightening

torques

(1) 2 Screws M10 X 1.5 X 20 37.5 ± 5 Nm

(2) 3 Screws M8 X 1.25 X 20 24.5 ± 2.5 Nm

(4) 2 Screw M12 X 1.75 X 30 32.5 ± 2.5 Nm

(5) 4 Screws M12 X 1.5 37.5 ± 2.5 Nm

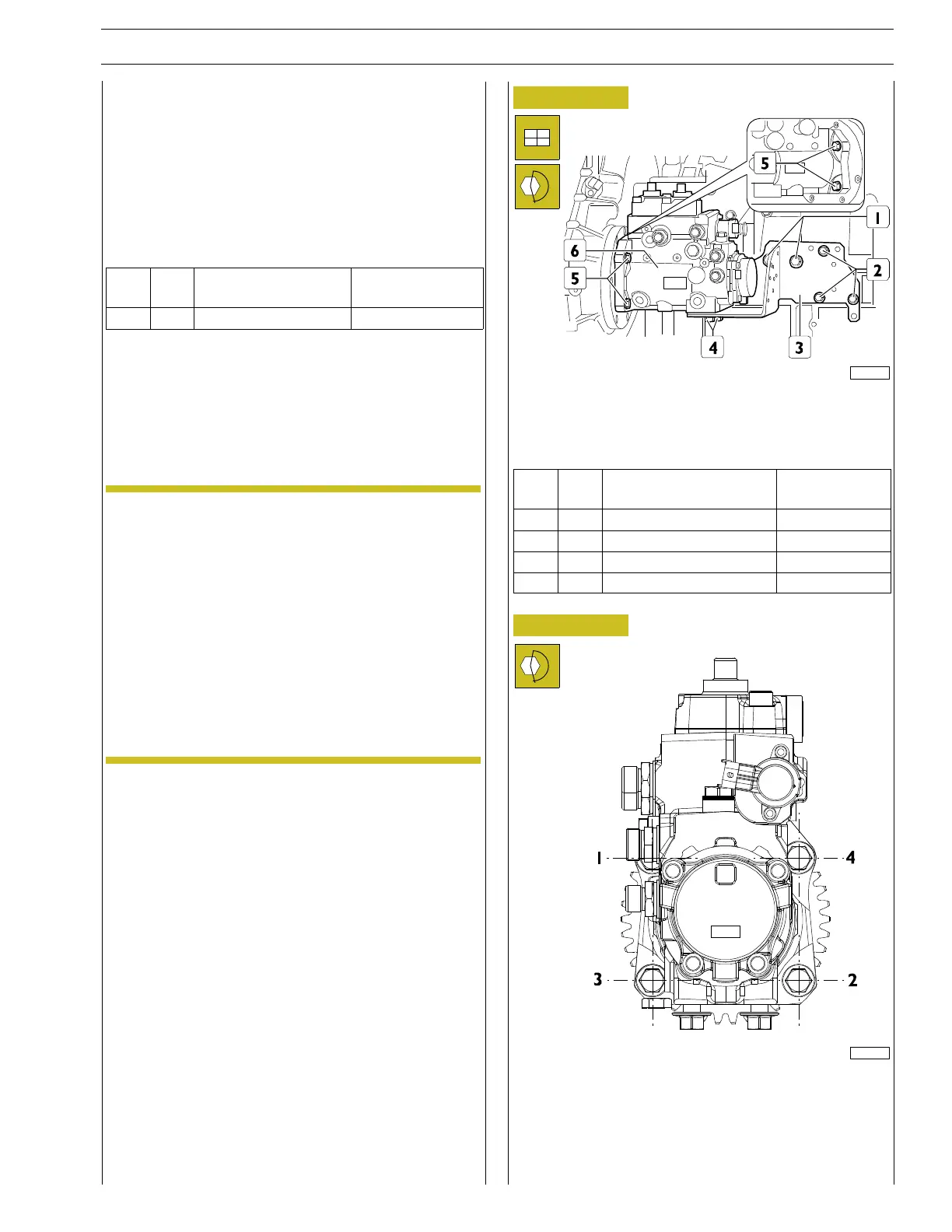

Figure 201

225012

Observe the order of tightening indicated in the diagram.

Loading...

Loading...