SECTION 6 - GENERAL MECHANICAL OVERHAUL

67

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

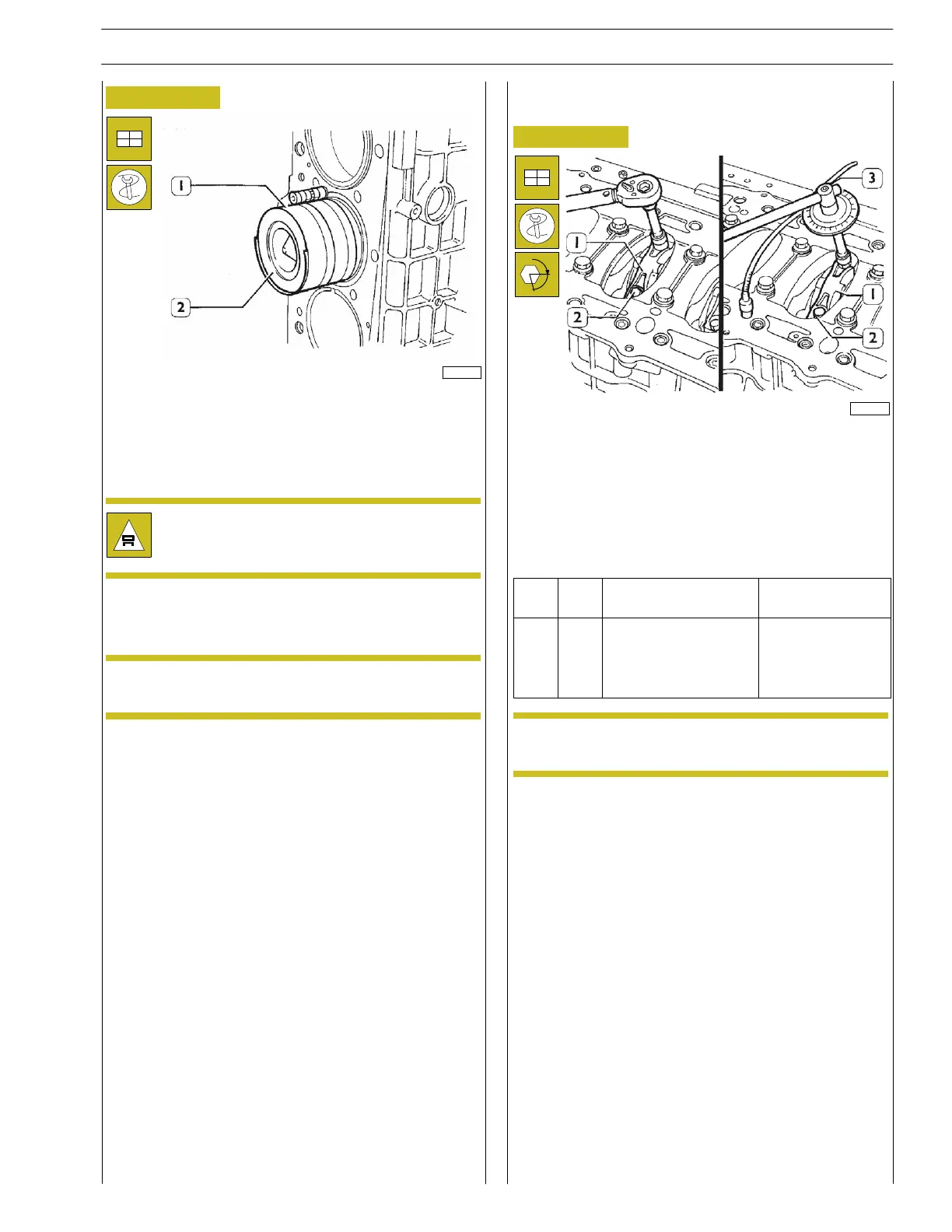

Figure 155

60616

Using the clamp to introduce the piston into the cylinder liner

99360603 (1), fit the piston-connecting rod assembly (2) into

the cylinder liners following the diagram in the previous Figure.

Check that the number of each connecting rod corresponds

to the cap coupling number .

During assembly, make absolutely sure that the

connecting rod does not hit against the cylinder

liner walls.

Check that the ideogram stamped on the piston crown faces

the engine flywheel; or the recess in the piston skirt matches

the position of oil nozzles .

NOTE The pistons are supplied as class A spare parts

and can also be fitted in class B cylinder liners.

Crankpin fitting clearance check

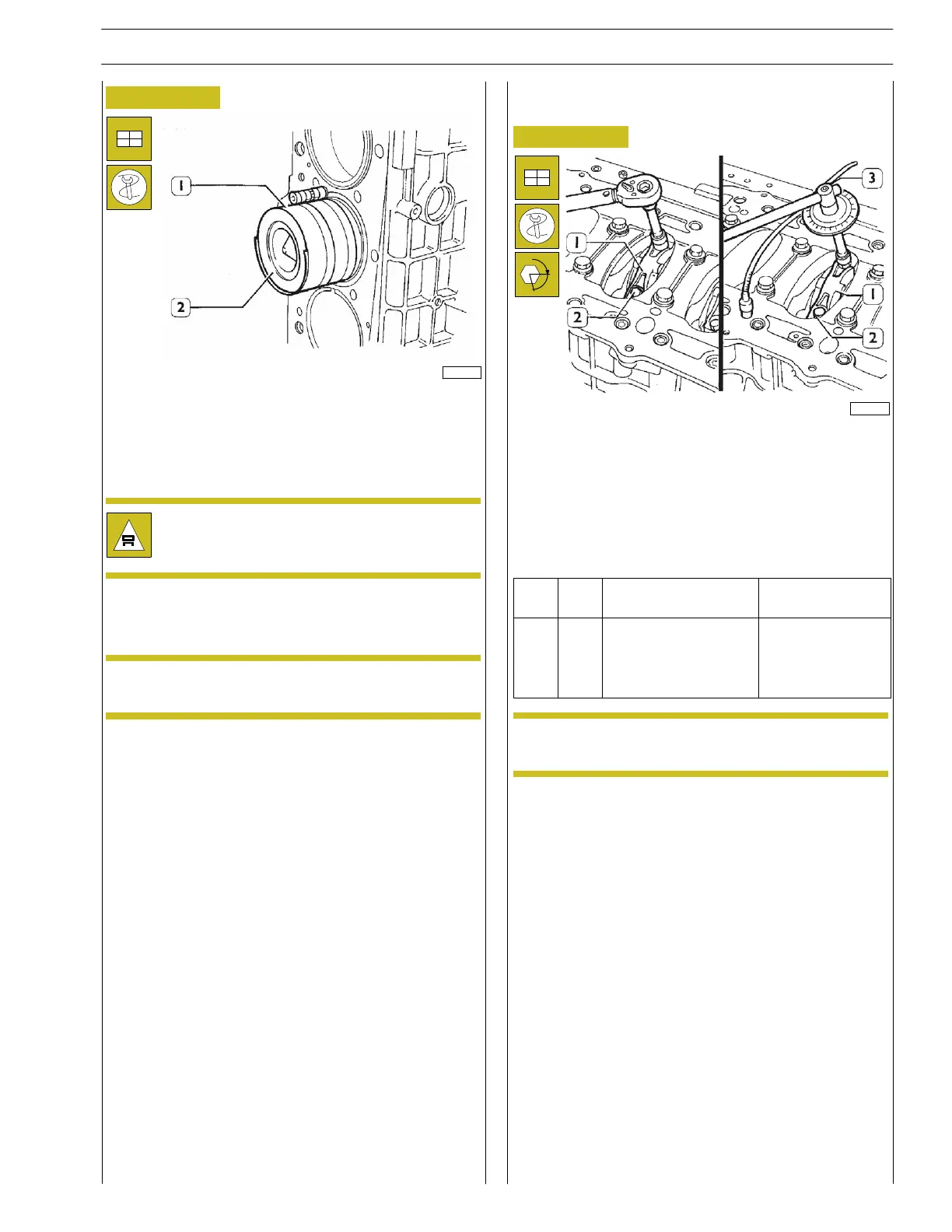

Figure 156

α

47594

Connect the connecting rods to the relevant journals of the

crankshaft, placing a length of calibrated wire on the journals.

mount the connecting rod caps (1) together with half-bearings;

tighten the screws (2) securing the connecting rod caps to the

prescribed torque.

Use tool 99395216 (3) to additionally tighten the screws to

the prescribed angle.

Ref.

No. Description

Tightening

torques

(2) 12

Screws fixing connec-

ting rod cap

M14 X 2

Step 1 70 Nm

Step 2 60˚

NOTE The thread of the screws (2), before assembly,

has to be lubricated with engine oil.

Remove the caps and check the clearance by comparing the

width of the calibrated wire with the scale calibration on the

envelope containing the wire.

Upon final assembly: check the diameter of the threading of the

screws (2) which must not be less than 13.4 mm, otherwise

replace the screw;

lubricate the crankpins and big end bearings; tighten the screws

(2) as described above.

Loading...

Loading...