46

SECTION 6 - GENERAL MECHANICAL OVERHAUL

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

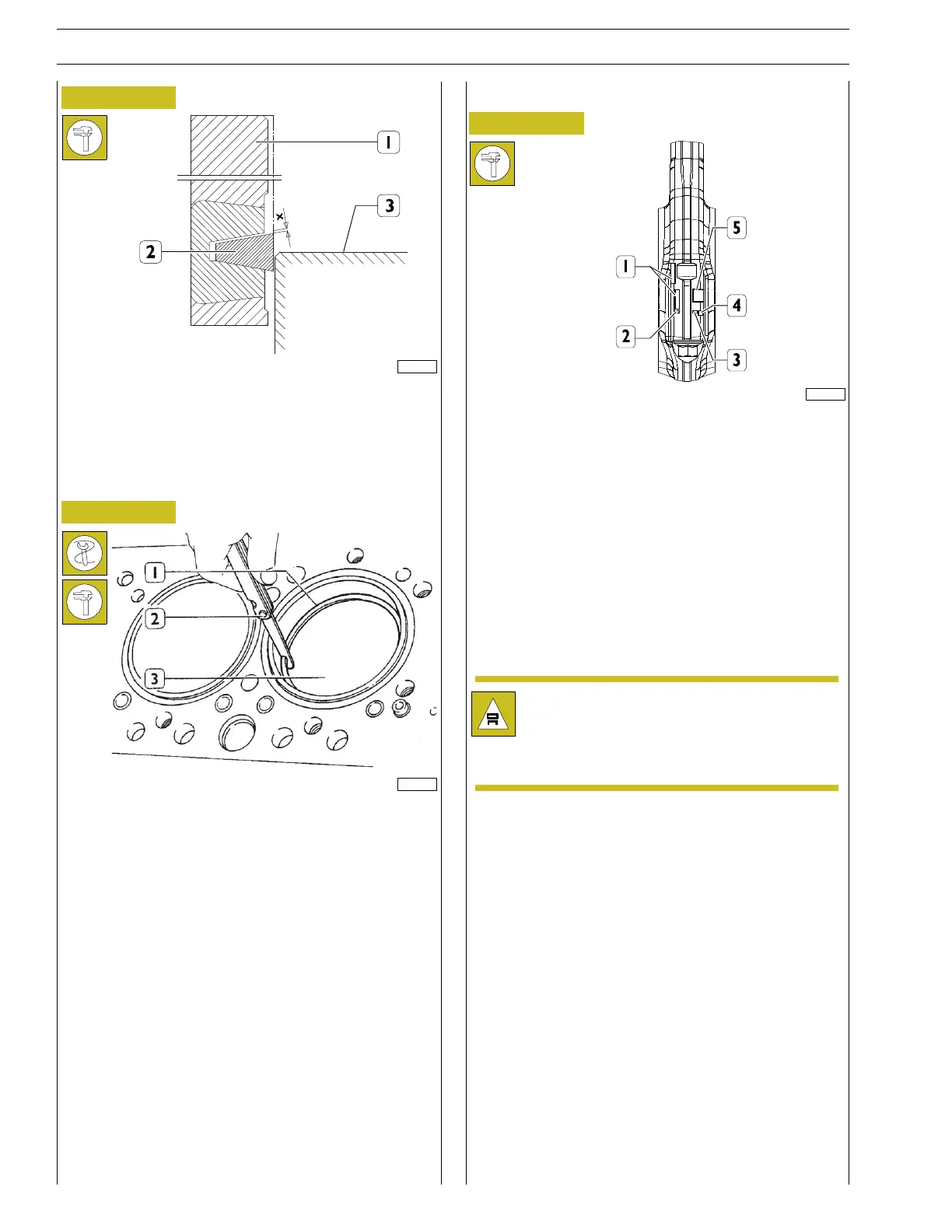

Figure 100

214628

The sealing ring (2) of the 1

º

seat is trapezoidal.

The clearance measurement ”X” between the sealing ring and

the housing is done by placing the piston (1) with the related

ring in the cylinder sleeve (3) so the half of the sealing ring

protrudes from the cylinder sleeve.

Figure 101

36134

Check the end gap of the sealing rings (1), using a feeler gauge

(2), entered in the cylinder liner (3).

If the distance between ends is lower or higher than the value

required, replace the circlips.

Connecting rod checks

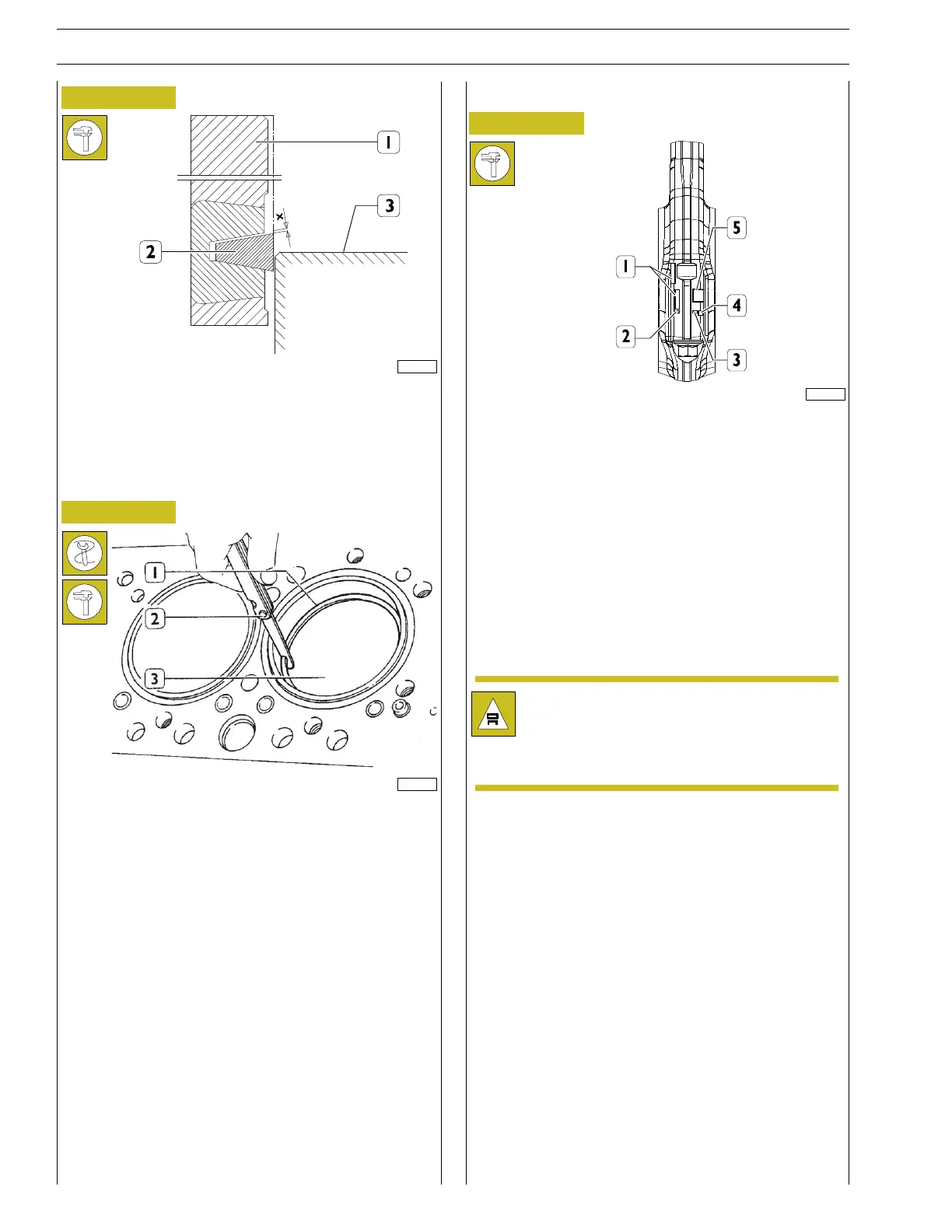

Figure 102

155939

1Standardnumbers

2 Letter indicating the weight class

A = 5502 - 5535 g.

B = 5536 - 5569 g.

C = 5570 - 5602 g.

3 Number indicating the selection of the diameter of the

big end bearing seat:

1 = 100.000 ÷ 100.010 mm

2 = 100.011 ÷ 100.020 mm

3 = 100.021 ÷ 100.030 mm

4Enginetype

5 Connecting rod identification plate

Connecting rods weight class

warning during assembly

When installing connecting rods, make sure they all

belong to the same weight class.

Data concerning the class section of connecting rod housing

and weight are stamped on the connecting rod.

Loading...

Loading...