SECTION 6 - GENERAL MECHANICAL OVERHAUL

63

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

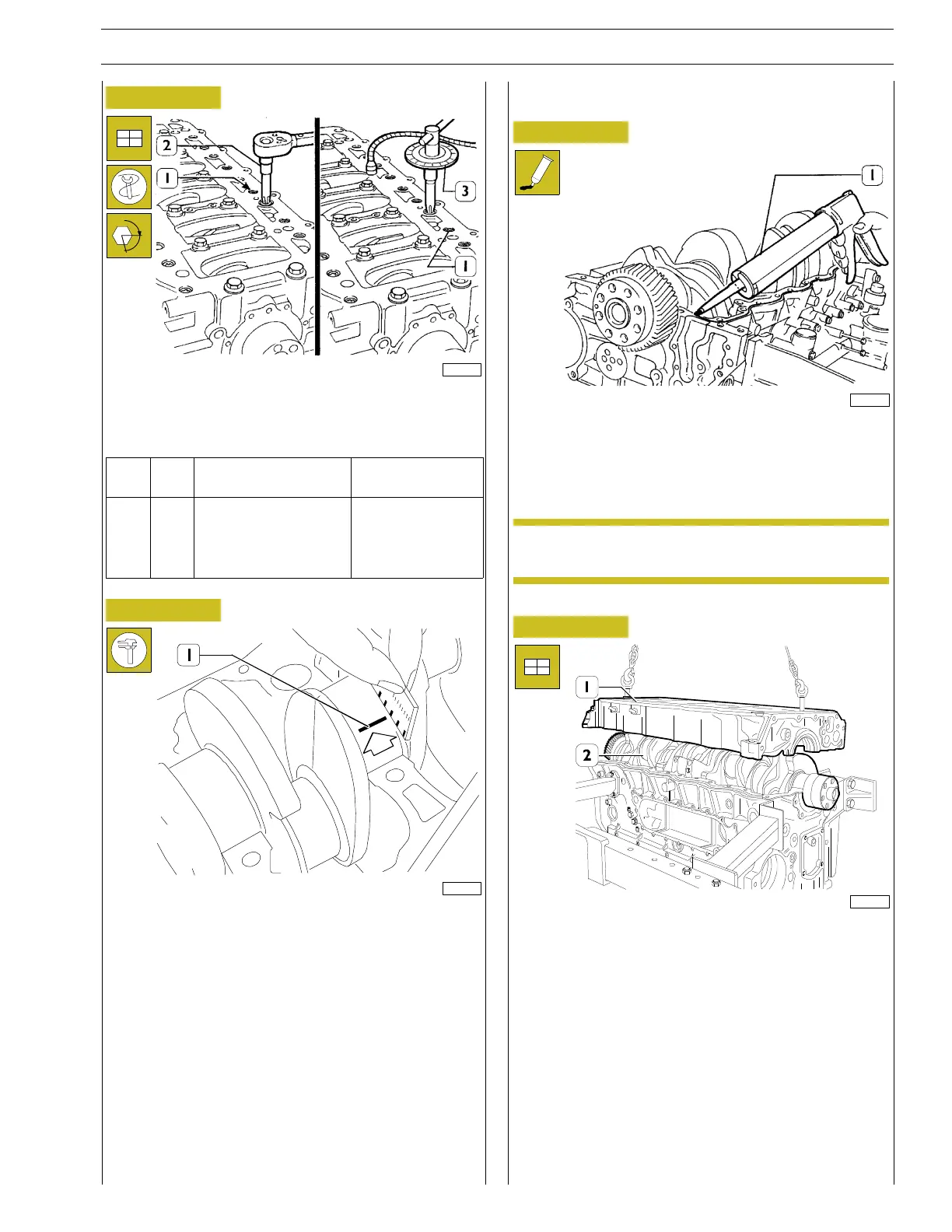

Figure 147

α

47581

Using a torque wrench 99395216 (2), tighten the outer

hex-socket screws (1) to the prescribed torque, then use the

specific tool (3) tighten to a specific angle.

Ref.

No. Description

Tightening

torques

(1) 26

Outer screws fixing

lower crankcase

M12X 1.75

Step 1 30 Nm

Step 2 60˚

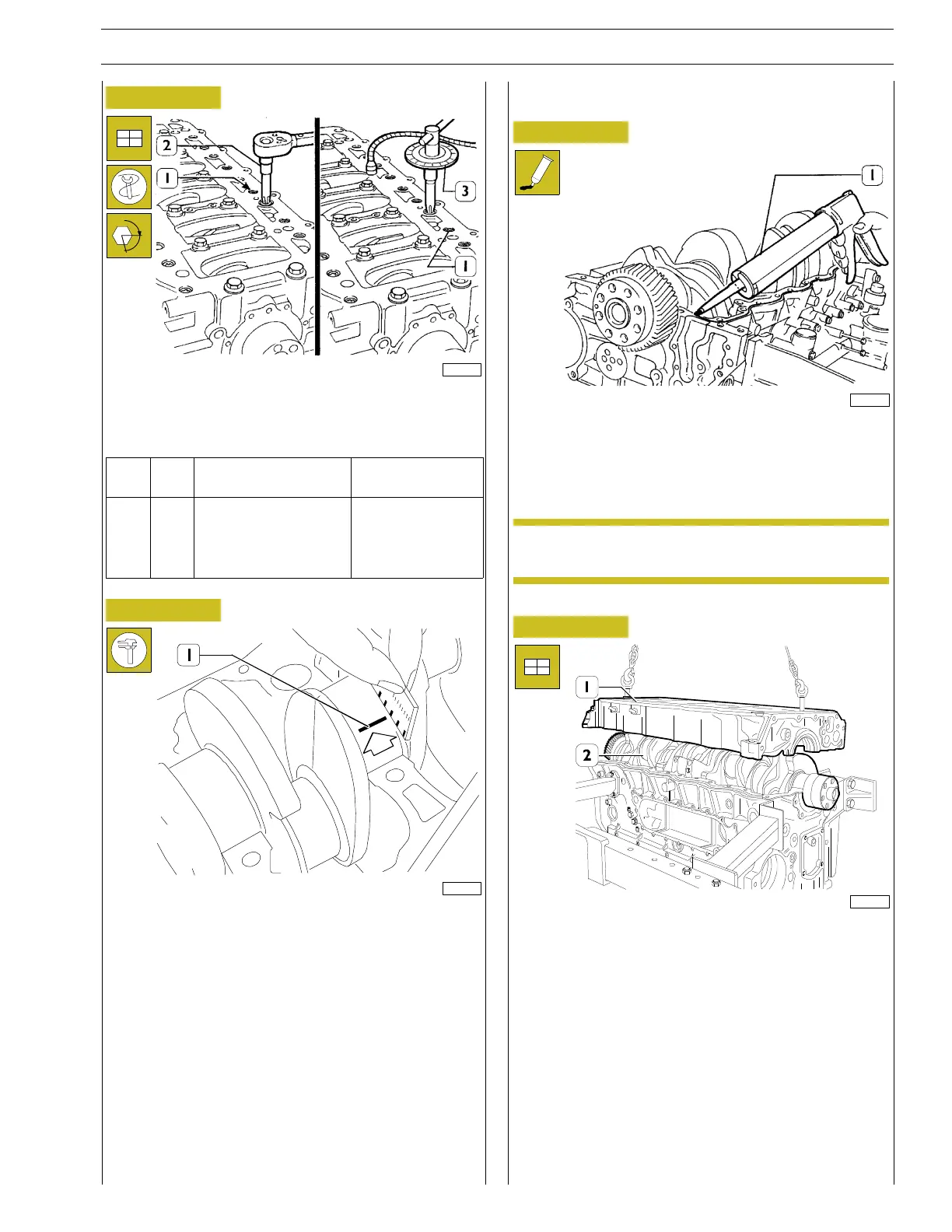

Figure 148

75310

Remove the lower crankcase.

The clearance between the main bearings and their pins is

measured by comparing the width of the calibrated wire (1),

at the point subjected to the greatest crushing forces, with the

graduated scale on the casing containing the calibrated wire.

The numbers on the scale indicate the clearance in millimetres

which should be between 0.055 and 0.083 mm.

If the clearance is not as prescribed, replace the bearings and

repeat the check.

lower crankcase assembly

Figure 149

47595

Apply LOCTITE 5970 onto the crankcase using the designated

tool (1)

Apply the sealant (LOCTITE 5970) following the indications

the figure.

NOTE Fit the lower crankcase within 10 minutes of ap-

plying the sealant.

Figure 150

60559

Fit the lower crankcase by means of a suitable hoist and hooks

(1).

Loading...

Loading...