42

SECTION 5 - R EMOVAL - REFITTING OF THE MAIN ENGINE COMPONENTS

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

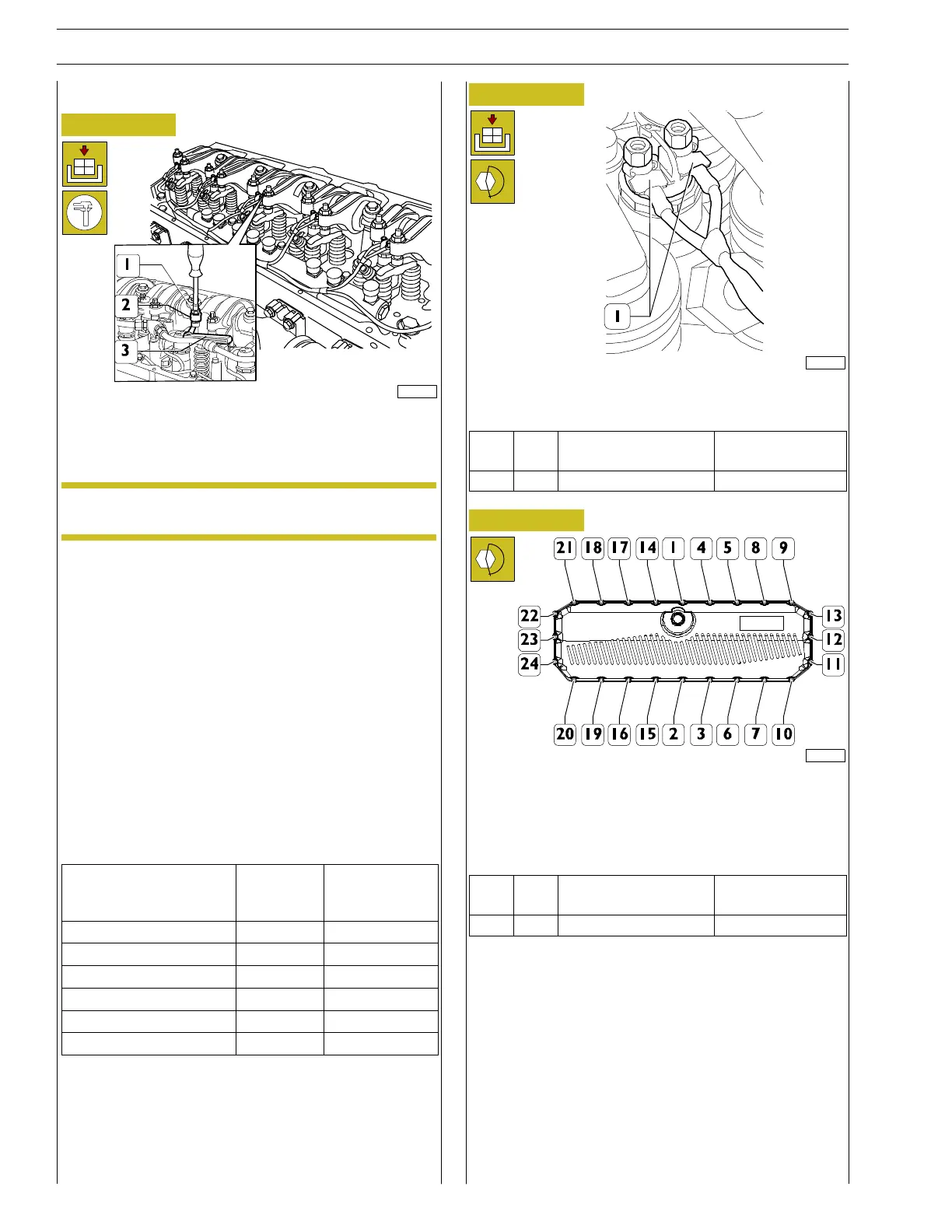

Setting rocker free play

Figure 120

114287

Take the cylinder whose clearance has to be adjusted into the

combustion phase; the valves of this cylinder are closed as they

balance those of the symmetric cylinder.

NOTE Thecorrespondenceofthe symmetrical cylinders

is1-6,2-5and3-4.

In order to properly operate, follow these instructions and

data specified on the table.

By means of a ratchet spanner, loosen the nut (1) locking the

adjustment screw.

Insert the feeler gauge blade (3) corresponding to the

operating clearance indicated in the table “Data and assembly

clearance” in SECTION 7 - Technical specifications.

Use a suitable wrench to screw or unscrew rocker arm (2)

adjusting screw.

Check that the thickness gauge blade (3) can slide with a slight

friction.

Lock the nut (1) holding the adjustment screw still.

To carry out the adjustments stated above, the sequence

showninthetableismandatory.

Start and rotation in the

engine direction

Balancing

cylinder

valves no.

Adjust valve

clearance for

cylinder no.

1and6atT.D.C. 6 1

120 degree of angle [˚] 3 4

120 degree of angle [˚] 5 2

120 degree of angle [˚] 1 6

120 degree of angle [˚] 4 3

120 degree of angle [˚] 2 5

Figure 121

183457

Connect the electrical connections (1) to the injectors and

block the cables using cable clamps.

Ref.

No. Description

Tightening

torques

(1) 12 Nuts M4 1.5 ± 0.25 Nm

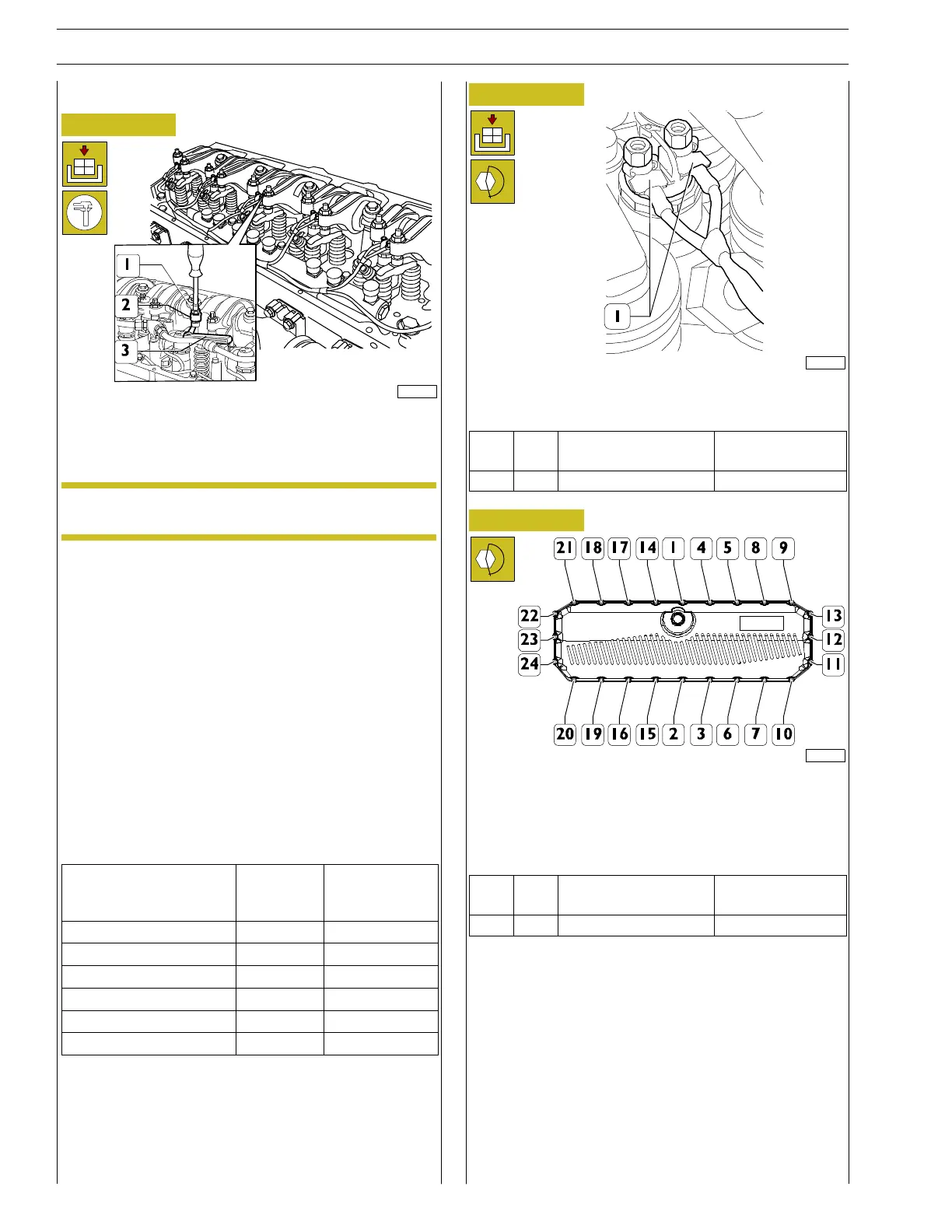

Figure 122

221122

Position the cover and new gasket and insert all the screws.

Replace the screws in the sequence 1-10-20-21-9 and then in

the sequence shown in the figure until contact.

Tighten the screws (1-24 ) to the torque specified in the table.

Ref.

No. Description

Tightening

torques

(-) 24 M6 x 1 screws 8.5 ± 1.5 Nm

Connect the electric connection of engine crankcase pressure

sensor.

Loading...

Loading...