SECTION 5 - REMOVAL - REFITTING OF THE MAIN ENGINE COMPONENTS

41

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

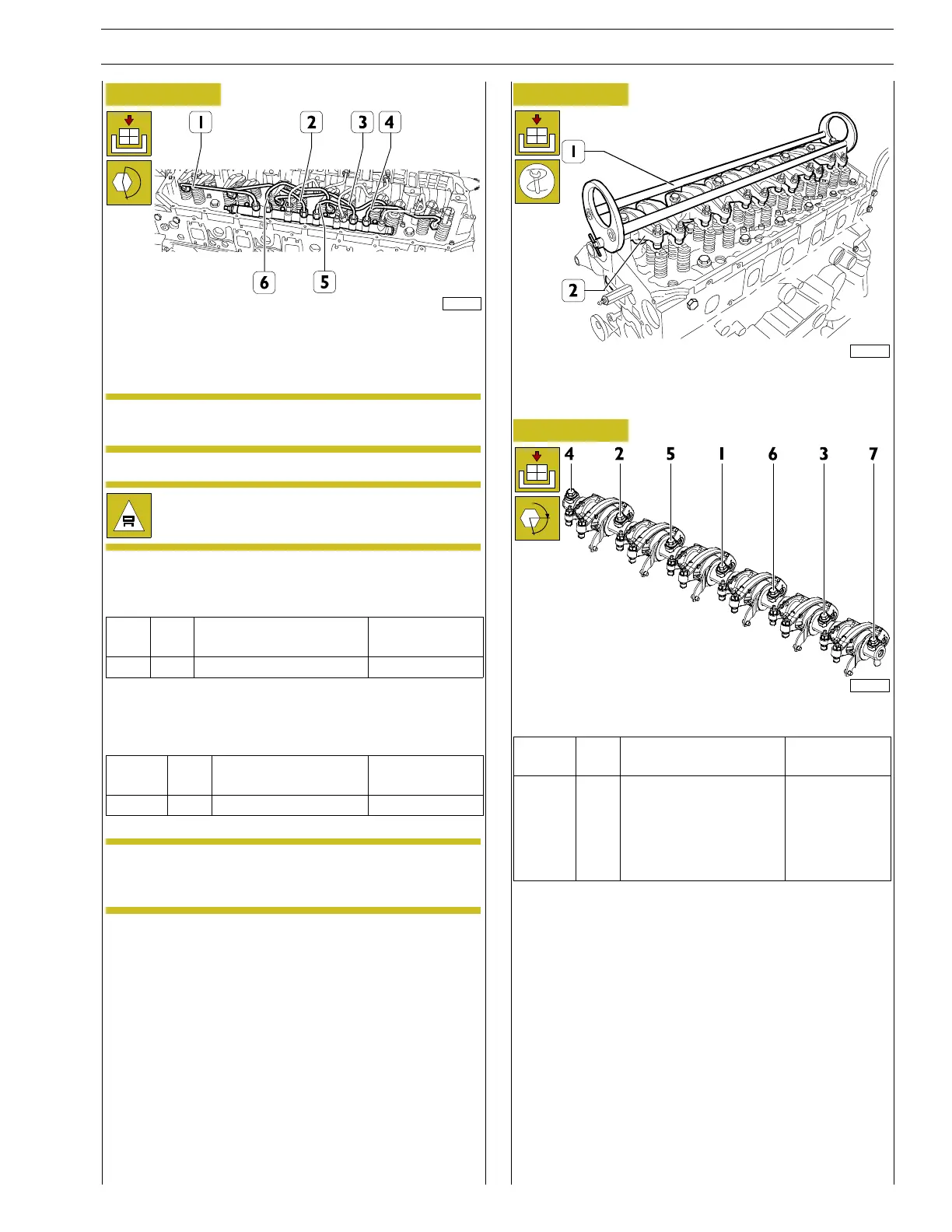

Figure 117

225054

Connect the high pressure fuel pipes and tighten the fittings by

hand in the sequence (1, 2, 3, 6, 5, 4) to the rail and the

injectors.

NOTE Before tightening the fittings to torque make sure

that the pipes (1) are not touching each other.

The high pressure fuel pipes must be replaced at each

disassembly.

Complete injector assembly operations by tightening the

bracket fastening screws to the torque shown in the table.

Ref.

No. Description

Tightening

torques

(-) 6 Screws M8 X 1.25 X 45 35 ± 2 Nm

Complete assembly of the high pressure fuel pipes (1, 2, 3, 6,

5, 4) by first tightening the injector side fittings and then those

ontherailsidetothetorqueshowninthetable.

Ref.

No. Description

Tightening

torques

(1 - 6) 12 Fittings M16 X 1.5 42.5 ± 2 Nm

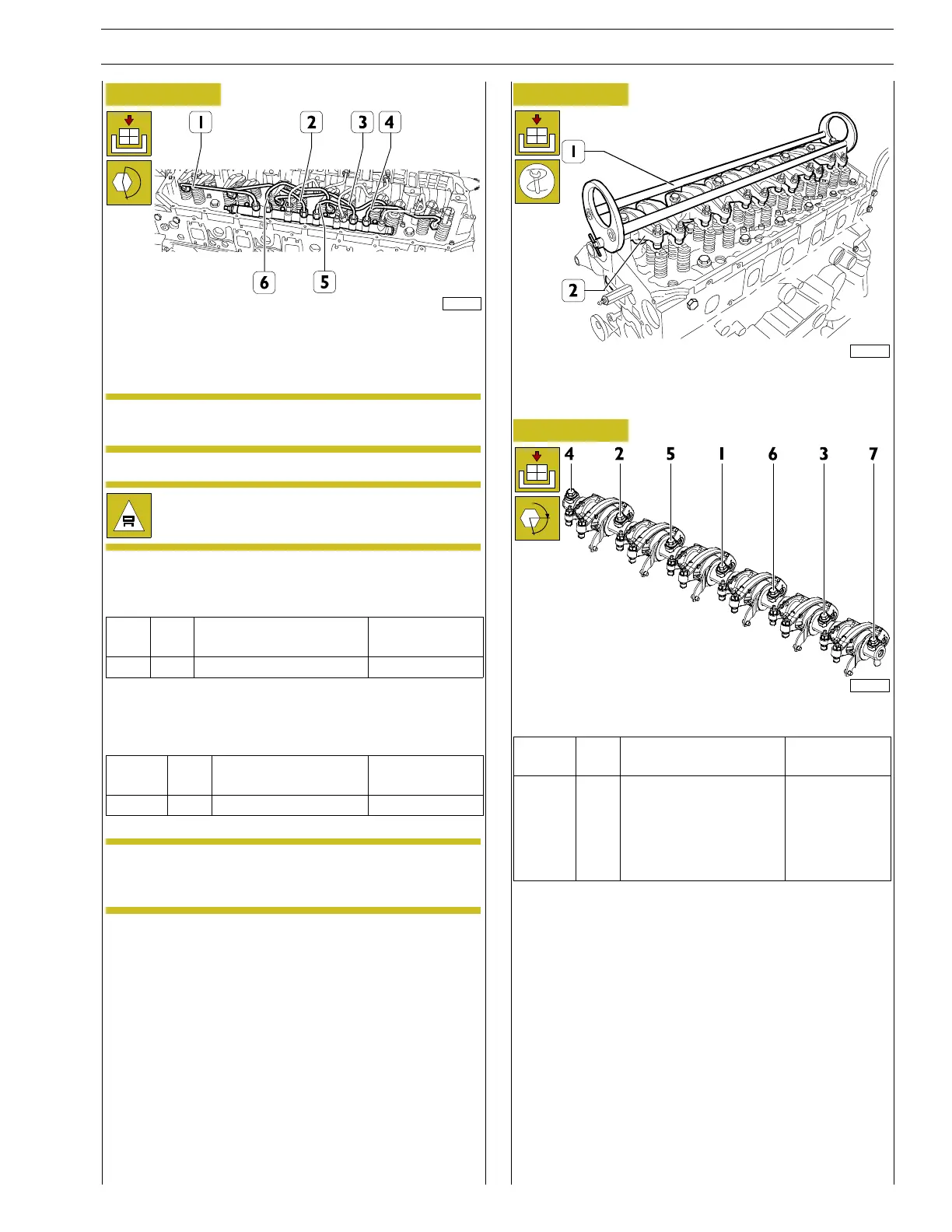

NOTE before refitting the rocker-arm shaft assembly,

make sure that all the adjustment screws have

been fully unscrewed.

Figure 118

225045

Apply the tool 99360553 (1) to the rocker arm shaft (2) and

mount the shaft on the cylinder head.

Figure 119

α

227746

Screw the screws in four steps as follows:

Ref.

No. Description

Tightening

torques

(1 - 7) 7

Screws M16 X 1.5 X 76

Step 1 25 Nm

Step 2 60 Nm

Step 3 80 Nm

Step 4 60˚

Tighteningsequence:1-2-3-4-5-6-7.

Loading...

Loading...