SECTION 5 - REMOVAL - REFITTING OF THE MAIN ENGINE COMPONENTS

33

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

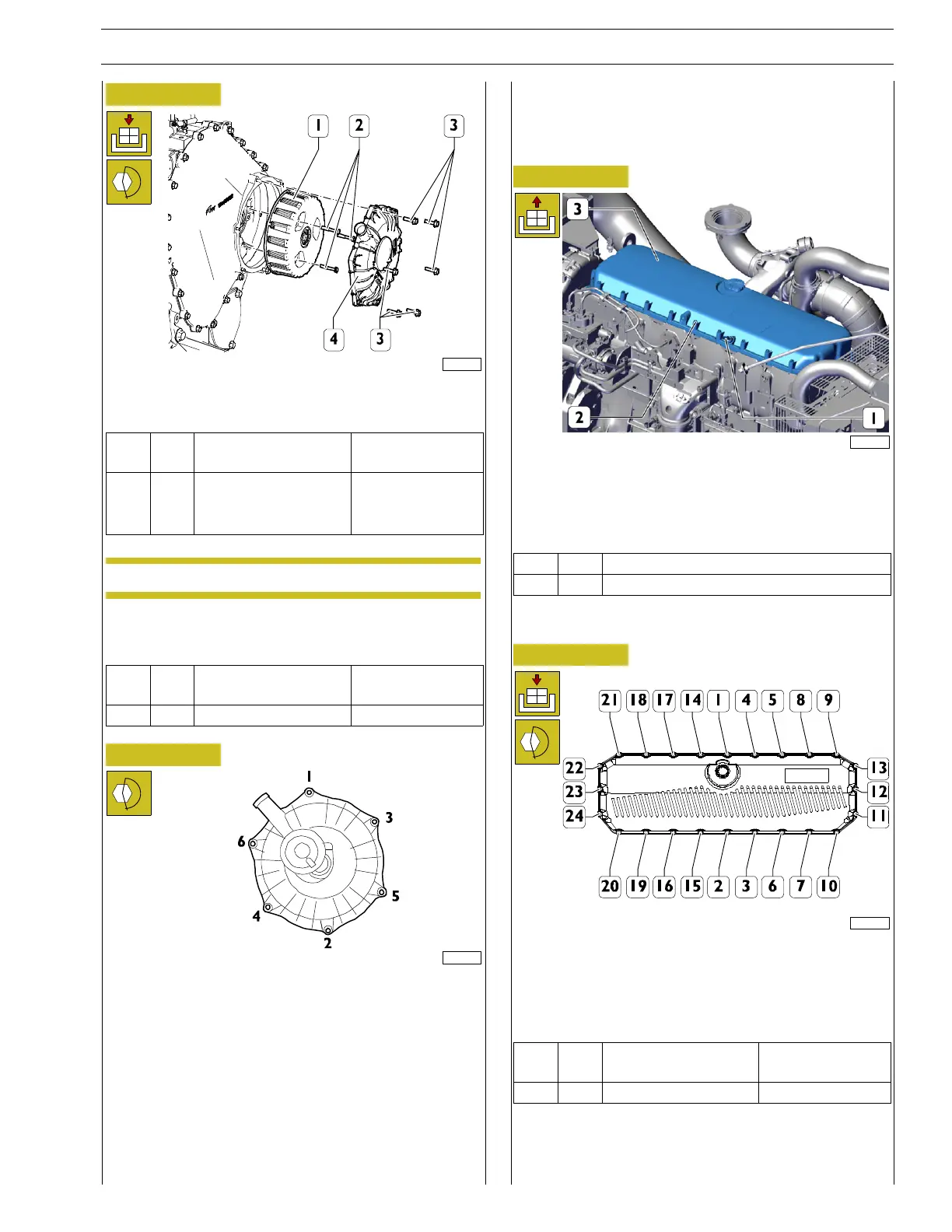

Figure 89

221043

Fit the new blow-by filtering element (1) into its seat and

tighten the screws (2) to the torque indicated in the table.

Ref.

No. Description

Tightening

torques

(2) 3

ScrewsM6X1X40

Step 1 5Nm

Step 2 15 ± 1.5 Nm

NOTE Apply Loctite 243 to the screws (2).

Position the blow-by cover (4) and tighten the screws (3) to

thetorqueindicatedinthetable.

Ref.

No. Description

Tightening

torques

(3) 6 ScrewsM6X1X25 7±1Nm

Figure 90

221126

Tighten the fastening screws following the sequence indicated

in the figure.

Refit the air filter as described in the procedure “AIR FILTER

REMOVAL - REFITTING”.

TAPPET COVER

REMOVAL-REFITTING

Removal

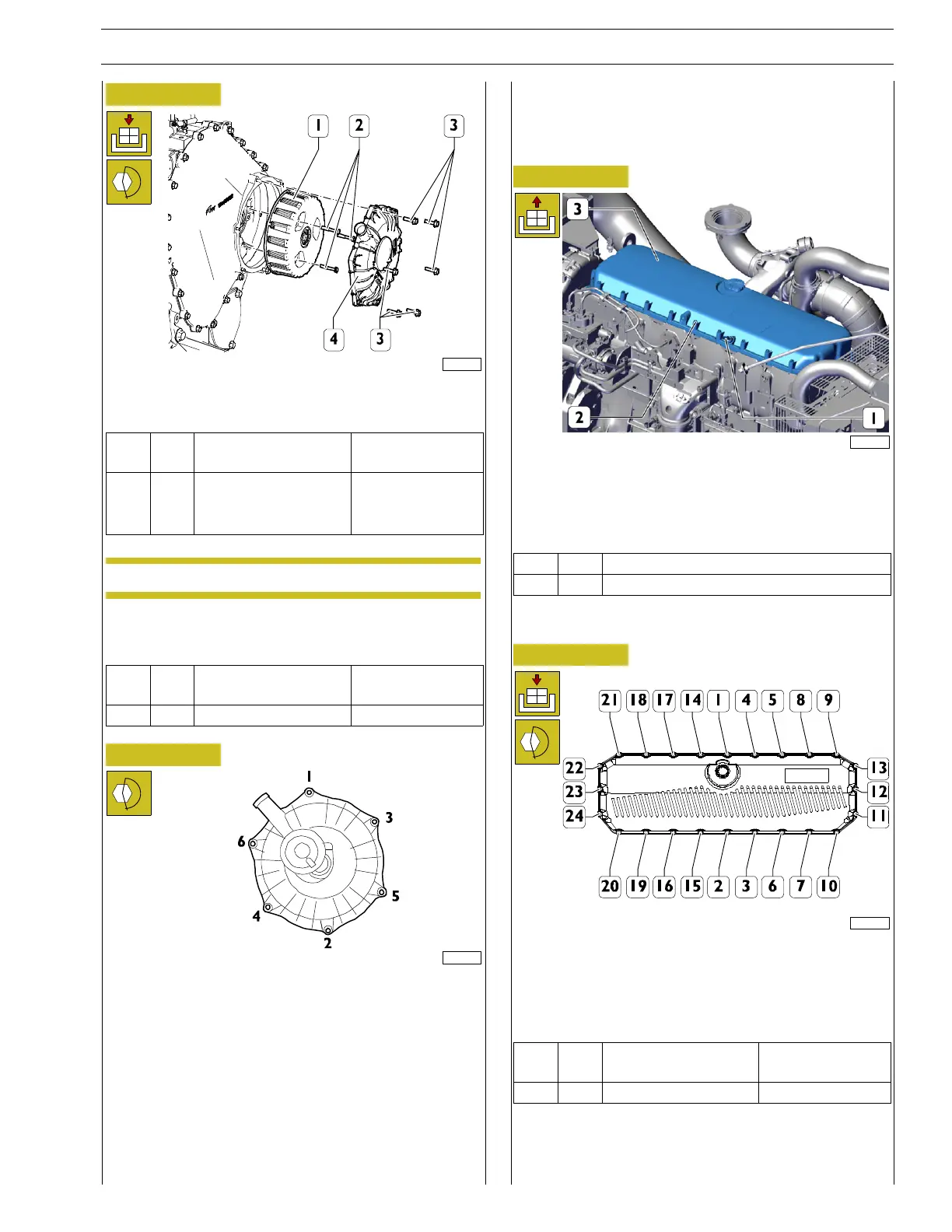

Figure 91

227771

Disconnect the electric connection of engine crankcase

pressure sensor (1).

Unscrew the fastening screws (2) and remove the tappet

cover (3) together with the gasket.

Ref.

No. Description

(2) 24 M6 x 1 screws

Refitting

Figure 92

221122

Position the cover and new gasket and insert all the screws.

Replace the screws in the sequence 1-10-20-21-9 and then in

the sequence shown in the figure until contact.

Tighten the screws (1-24 ) to the torque specified in the table.

Ref.

No. Description

Tightening

torques

(-) 24 M6 x 1 screws 8.5 ± 1.5 Nm

Connect the electric connection of engine crankcase pressure

sensor (1).

Loading...

Loading...