SECTION 4 - SCHEDULED MAINTENANCE

13

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

UNSCHEDULED MAINTENANCE

- HOW TO PROCEED

Visual turbocharger inspection

Only proceed when the engine is not turning over.

Visually check that the turbine, impellers of the compresser

and the relative intake/outlet pipes are not obstructed or da-

maged. Otherwise replace as necessary.

Check for any soot between the intake manifold and the tur-

bocharger, replace the gasket if soot is found.

Check the conditions of the turbocharger gasket (e.g. breaka-

ges, deformation, ...), replace if necessary.

Make sure that the wastegate control tie-rod is well tighte-

ned, lubricated and not out of shape.

Clean the heat exchanger (radiator)

Figure 14

227785

Check that the air intake surfaces of the radiators are free of

impurities (dust, mud, straw etc.).

Clean them if necessary using compressed air or steam.

!

When using compressed air, it is required to use

suitable personal protections for hands, face and

eyes.

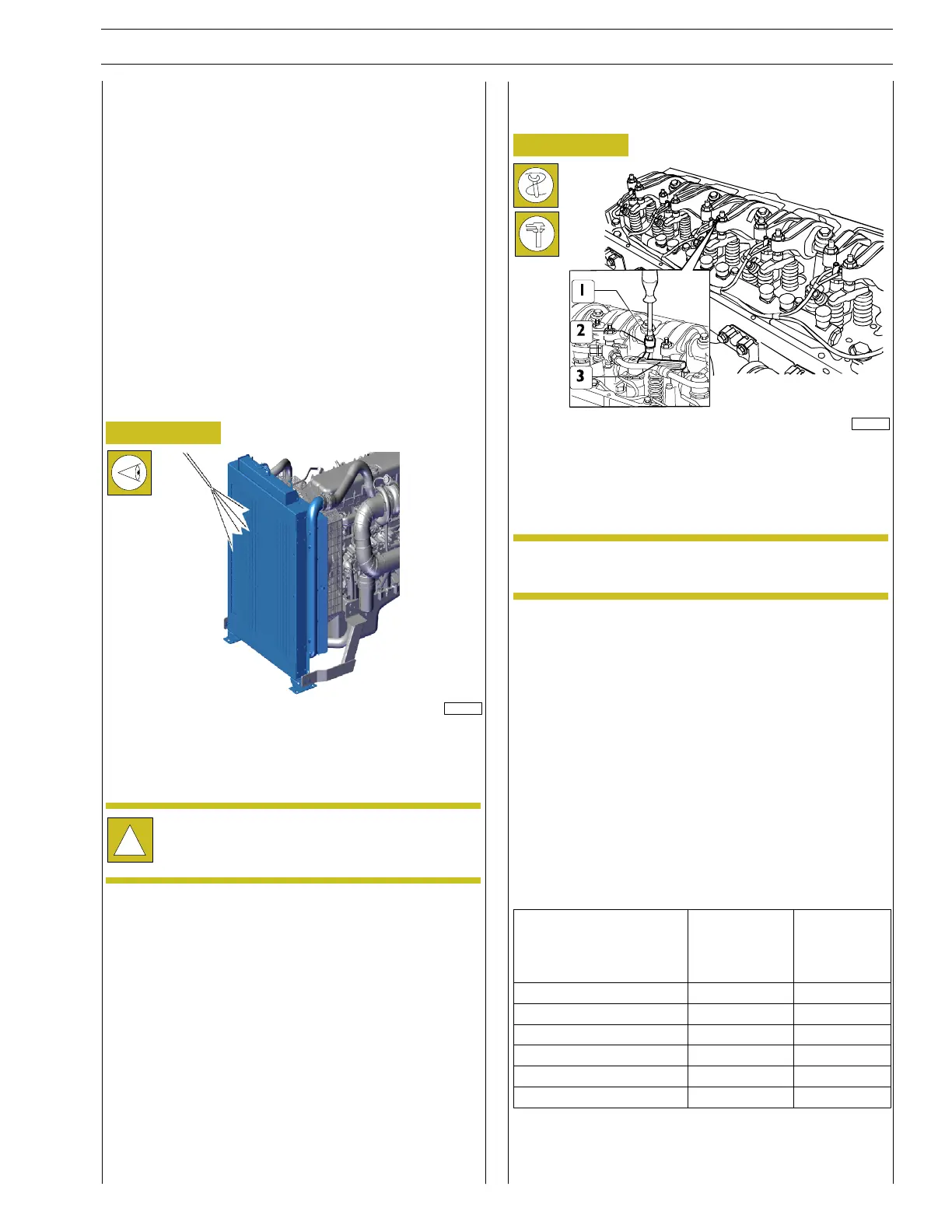

Check the tappet clearances and adjusting if

necessary

Figure 15

114287

Remove the tappet cover

Take the cylinder whose clearance has to be adjusted into the

combustion phase; the valves of this cylinder are closed as

they balance those of the symmetric cylinder.

NOTE The correspondence of the symmetrical cylin-

dersis1-6,2-5and3-4.

In order to properly operate, follow these instructions and

data specified on the table.

By means of a ratchet spanner, loosen the nut (1) locking the

adjustment screw.

Insert the feeler gauge blade (3) corresponding to the opera-

ting clearance indicated in the table “Data and assembly clea-

rance” in SECTION 7 - Technical specifications.

Use a suitable wrench to screw or unscrew rocker arm (2)

adjusting screw.

Check that the thickness gauge blade (3) can slide with a slight

friction.

Lock the nut (1) holding the adjustment screw still.

To carry out the adjustments stated above, the sequence

showninthetableismandatory.

Start and rotation in the

engine direction

Balancing

cylinder

valves no.

Adjust valve

clearance

for cylinder

no.

1 and 6 at T.D.C. 6 1

120 degree of angle [˚] 3 4

120 degree of angle [˚] 5 2

120 degree of angle [˚] 1 6

120 degree of angle [˚] 4 3

120 degree of angle [˚] 2 5

Complete the operation by mounting the tappet cover and

its gasket.

Loading...

Loading...