SECTION 6 - GENERAL MECHANICAL OVERHAUL

51

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

Checking the planarity of the head on the

cylinder block

Figure 112

198344

Check the supporting surface (1) of the head on the cylinder

assembly with a rule (2) and a feeler gauge (3).

If you find any deformation, level the head on a surface grinder;

maximum amount of material that can be removed 0.2 mm.

NOTE After this operation, check valve recessing and

injector protrusion.

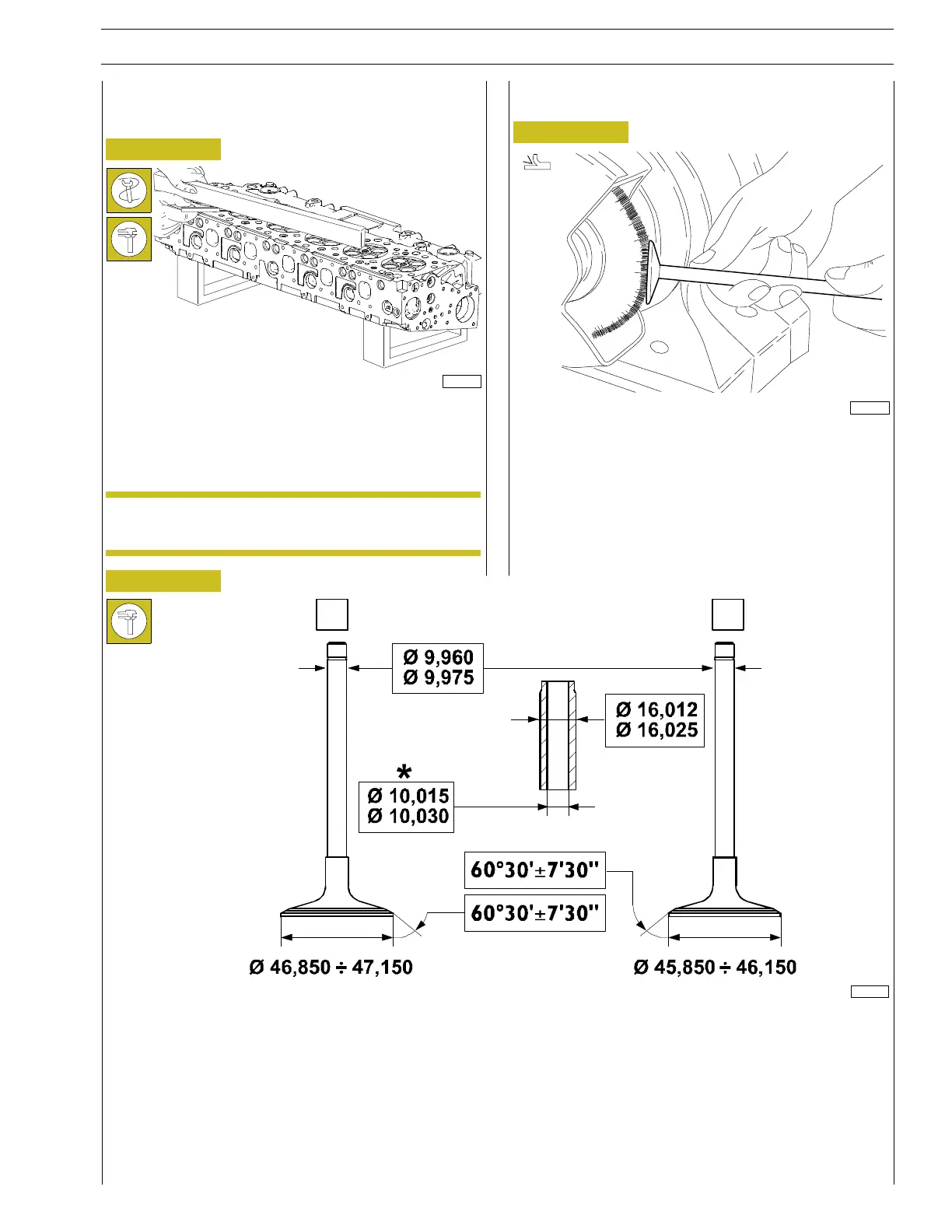

Valve descale and check

Figure 113

204301

Remove all carbon deposits from the valves using a wire brush.

Figure 114

A B

155953

* = Value to be obtained after driving in the valve guides

A = intake - B = exhaust

Check that the valves show no signs of seizure or cracking and also check with a micrometer that the valve stem diameter is within

the required values: replace the valves if it is not.

Regrind the valve seats, if required,usingagrindingmachineandremovingaslessmaterialaspossible.

Use a bore gauge to check that the diameter inside the valve guide corresponds to the value indicated, after fitting.

Loading...

Loading...