80

SECTION 6 - GENERAL MECHANICAL OVERHAUL

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

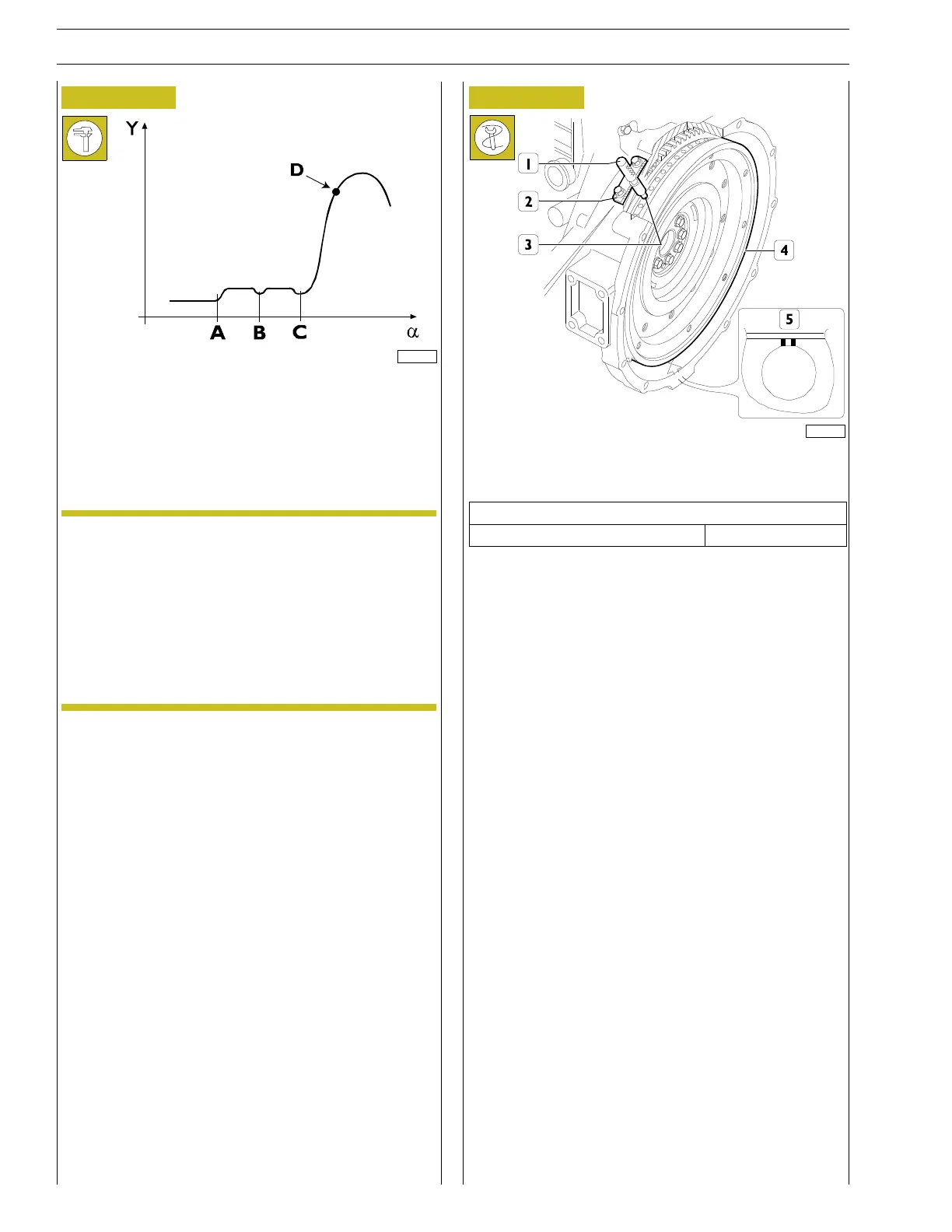

Figure 194

185524

Camshaft rotation angle

Y Cam lift based on the rotation angle of the camshaft

D Cam lift in correspondence of the 54˚ before the top

dead centre , 1st cylinder end of compression

Reset the dial gauge first in point A.

NOTE The dial gauge is to be zeroed with the rocker arm

roller in contact with the base radius of the cam

profile .

For this, turn the flywheel until it exceeds protru-

sions (A-B) and (B-C) on the cam profile connec-

ted to the engine brake operation.

This condition occurs when the flywheel is turned

in the opposite direction of the operating direction

by approx. 1 and 1/4 rotations.

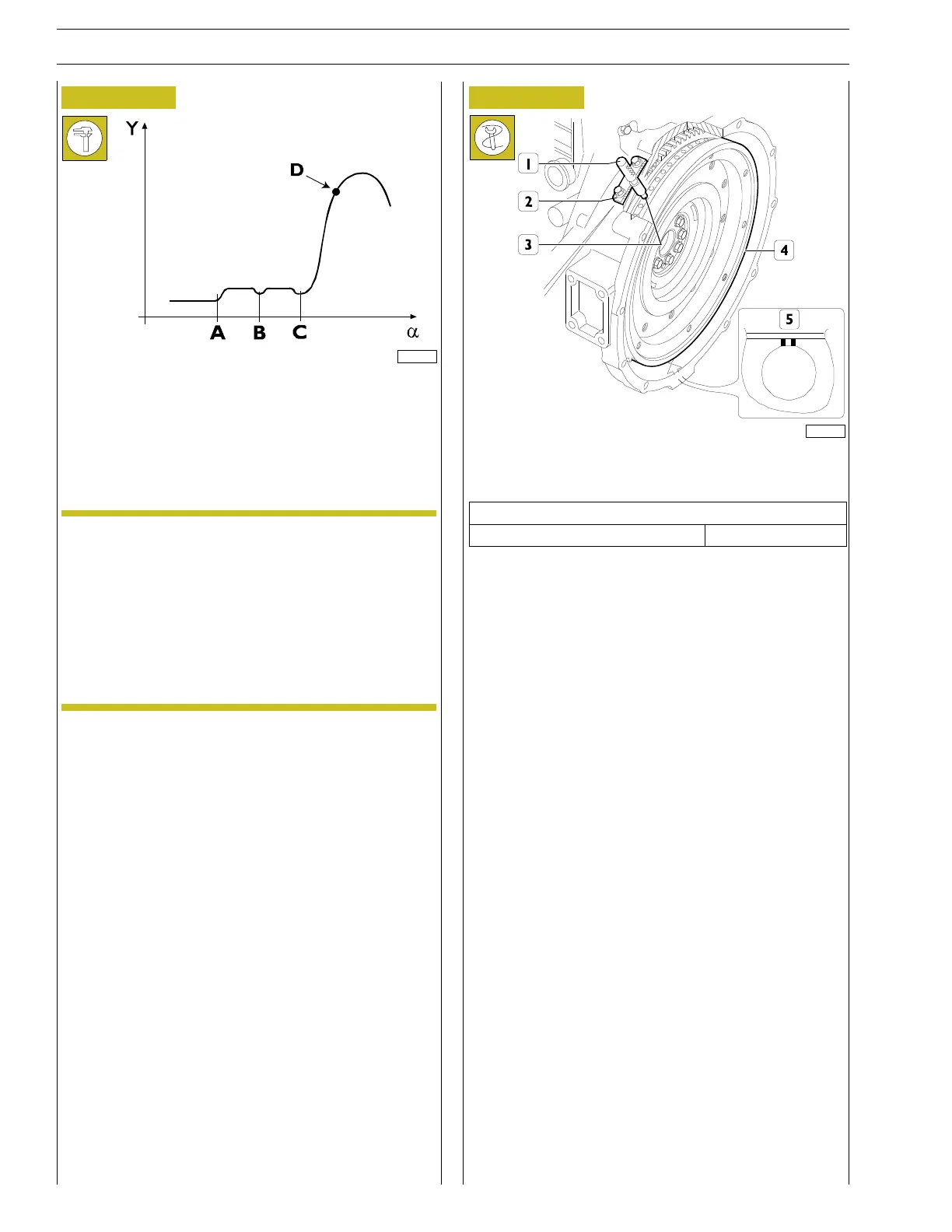

Figure 195

185523

Turn the engine flywheel in the engine operating direction until

the dial gauge indicates the required camshaft lift value.

Technical data

Cam timing dial gauge value 5.95 ± 0.05 mm

Check that the required cam lift values are displayed under the

following conditions:

- Theholewithtwonotches(5)isvisiblethroughthesmall

inspection window.

- The tool 99360612 (1), through the seat (2) of the engine

speed sensor , enters the hole (3) in the engine flywheel

(4).

Loading...

Loading...