4 Transport, installation and commissioning

Installation

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

Page

4 - 15

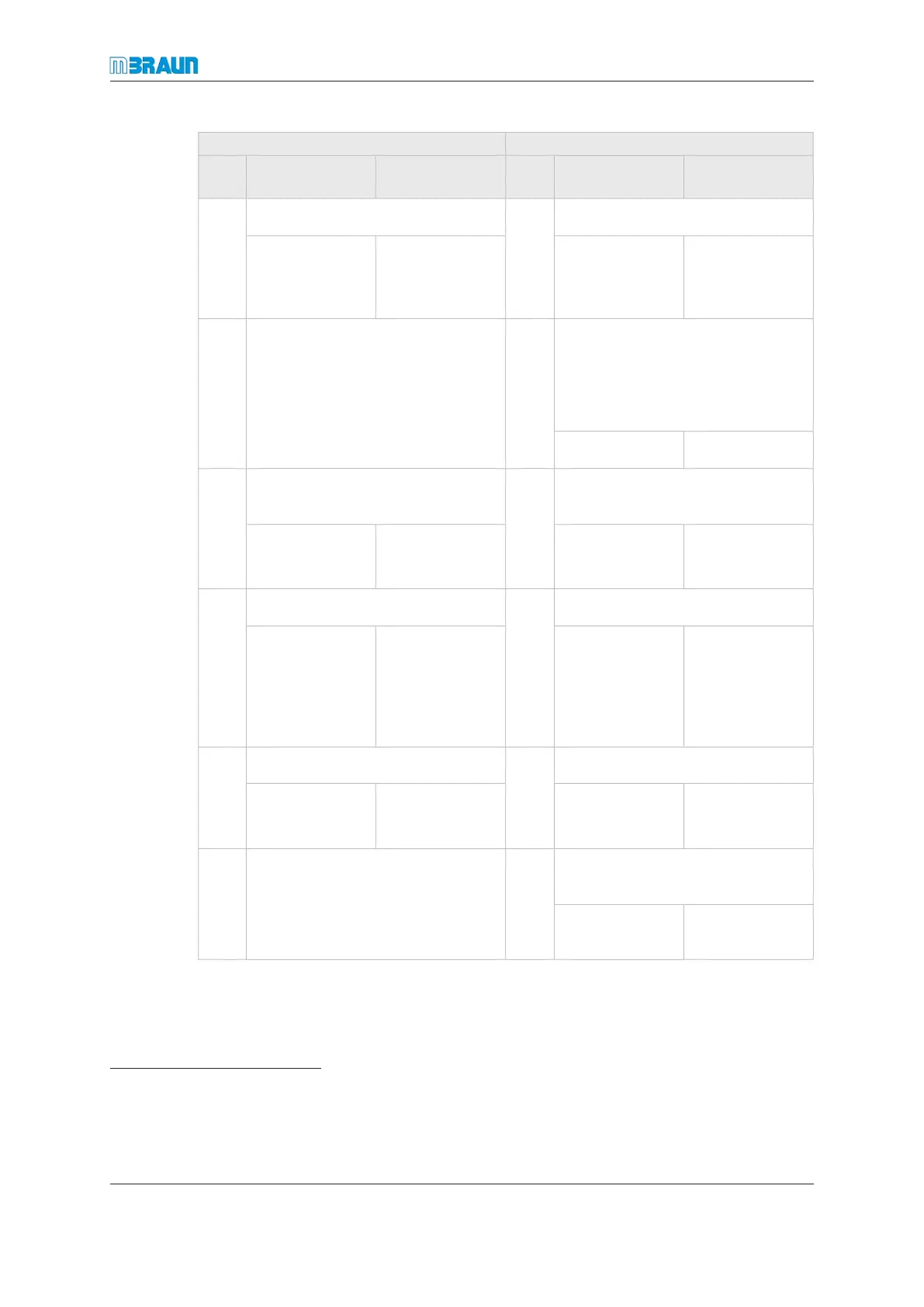

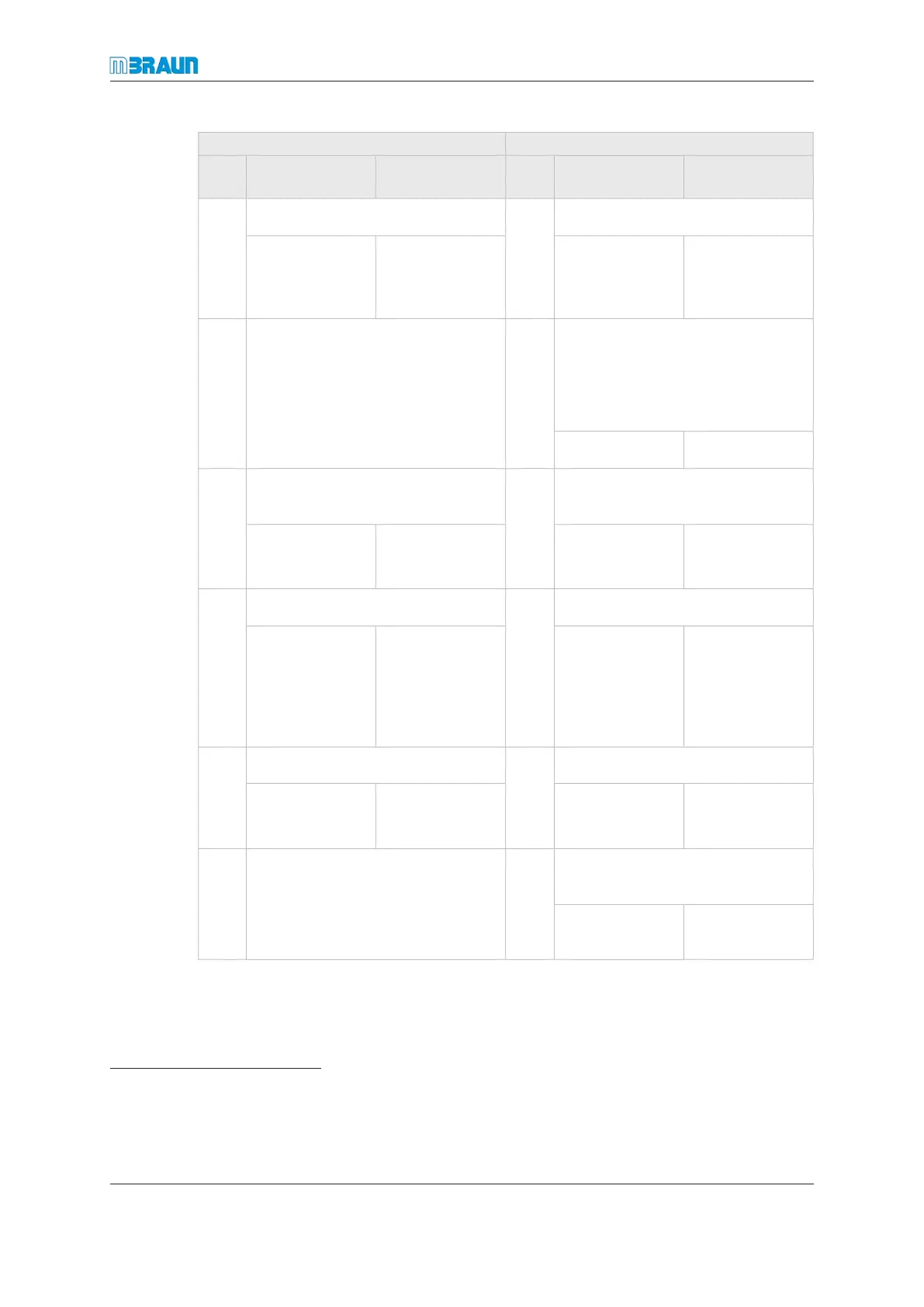

Inlet Outlet

Pressure at sup-

ply point

Flange at connec-

tion point

Pressure at con-

nection point

Flange at connec-

tion point

1a Working gas INLET 1b Vacuum pump EXHAUST

5.5 – 6.0 bar

(0.55 – 0.60

MPa)

∅ 10 mm

Depressurized DN 25

2b Working gas purge outlet with op-

tional features

¡ glovebox purge (MB-BS-200)

¡ ECO Mode (MB-ECO Mode)

Depressurized Ø 42.5 mm

3a Regeneration gas INLET (for

RKM )

3b Regeneration gas EXHAUST (for

RKM and MB-LMF 2/40 REG )

0.3 … 0.5 bar

(30 … 40 kPa)

Ø 10 mm Depressurised Ø 10 mm

4a Cooling water INLET 4b Cooling water OUTLET

2.0 bar (0.2

MPa) … max.

2.5 bar (0.25

MPa)

10°C … 15°C

Ø 10 mm Low pressure Ø 10 mm

5a Box Purge

11

INLET 5b Box Purge* OUTLET

2.0 bar

(0.2 MPa)

Ø 10 mm Low pressure KF40, Ø

44.5mm

6b Option: Pressure relief valve OUT-

LET (OSV valves)

Low pressure KF40, Ø

44.5mm

The table above shows an overview about the inlets and outlets. The following sections

give further information. The numbers used in the titles correspond to the numbers in the

table.

11

Glovebox is purged directly from an external working gas source (gas purifier is bypassed):

¡ during manual inertisation through an open flange and a hose,

¡ as an optional (Siemens PLC-controlled feature) for glovebox operation.

Loading...

Loading...