Field Service Ver. 1.0 Jun. 2008 3. Periodical check

9

Maintenance

Maintenance

3. Periodical check

3.1 Maintenance items

NOTE

• Cleaning/replacement cycle for each maintenance item of main body/options can

be evaluated with each life counter value of [Service mode] o [Counter] o [Life].

3.1.1 Main body

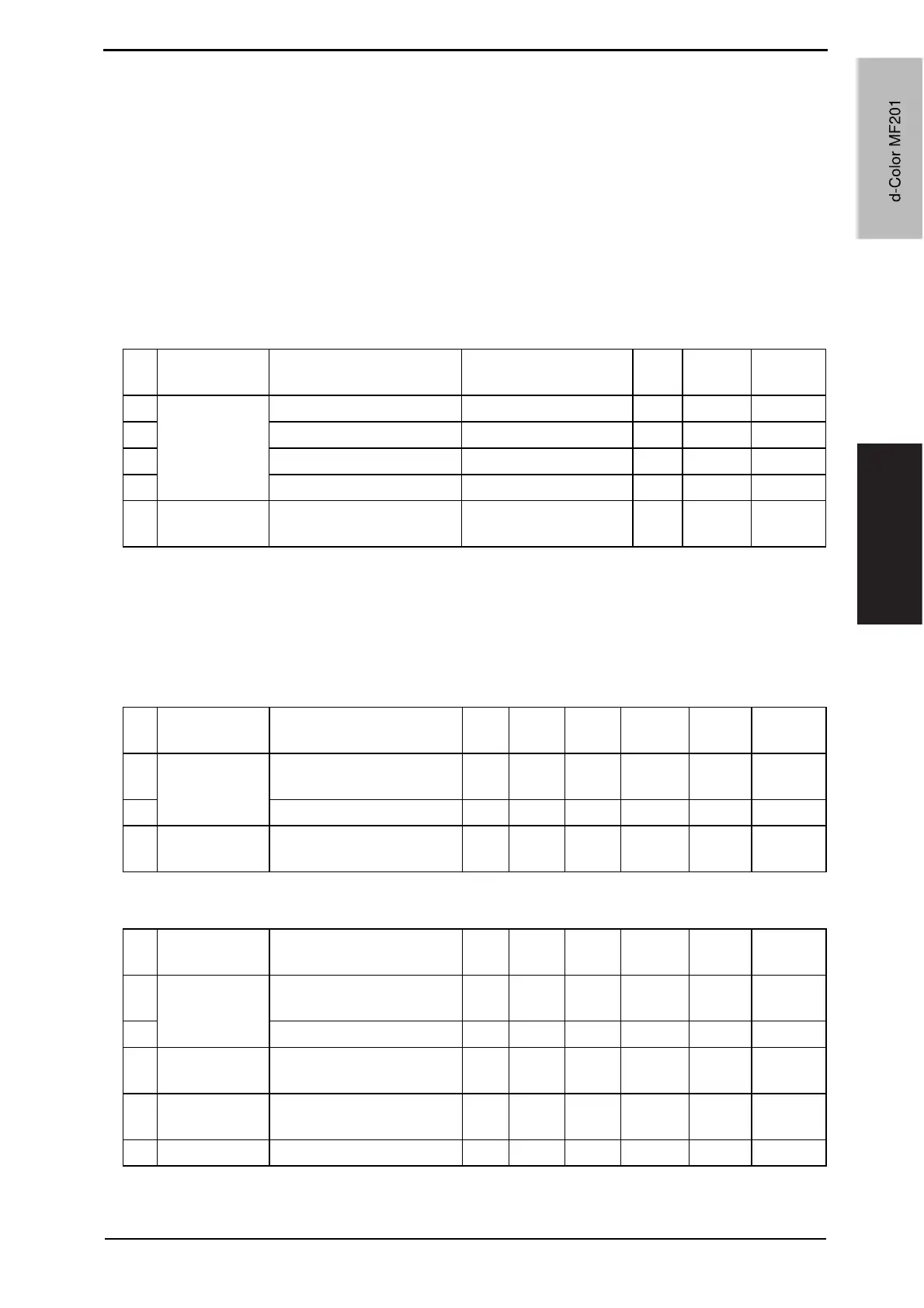

A. Parts to be replaced by users (CRU)

*1: The parts can be replaced either by user or service engineer.

For details of setting, see [Unit Change] on “Adjustment/Setting.”

See P.251

*2: A waste toner full condition is detected with detecting the actual waste toner emissions.

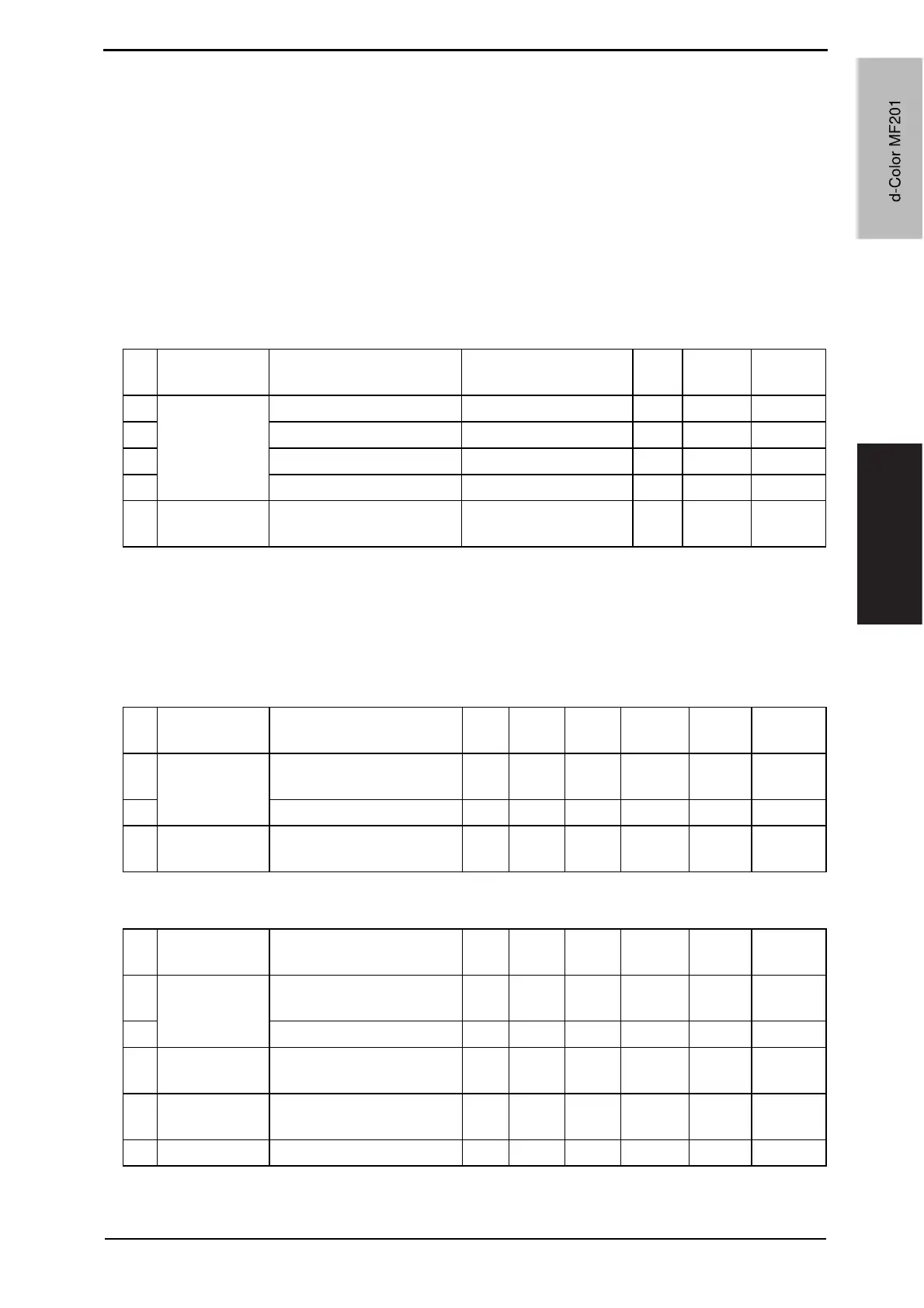

B. Maintenance call (per 30,000-sheet scan)

C. Maintenance call (per 60,000-print)

No Class Parts to be replaced Cycle Clean Replace

Descrip-

tions

1

Processing

sections

Imaging unit Y,M,C 45,000 ● *1

2 Imaging unit K 60,000 ● *1

3 Toner cartridge Y,M,C 18,500 ● *1

4 Toner cartridge K 24,000 ● *1

5

Image transfer

section

Waste toner box (50,000) ● *1,2

No. Class Parts to be replaced Qt. Check Clean Replace

Lubri-

cation

Descrip-

tions

1

Overall

Paper feed and image

conditions

●

2 Appearance ●●

3

Scanner

section

Original glass assy ●

No. Class Parts to be replaced Qt. Check Clean Replace

Lubri-

cation

Descrip-

tions

1

Overall

Paper feed and image

conditions

●

2 Appearance ●●

3

Conveyance

section

Timing roller ●

4

Image transfer

section

Around waste toner port ●

5 AD-505 Duplex transport roller ●

Y109660-1 Sevice Manual

d-Color MF201

Loading...

Loading...