Creating a ShopMill program

7.3 Basic information

Milling

224 Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

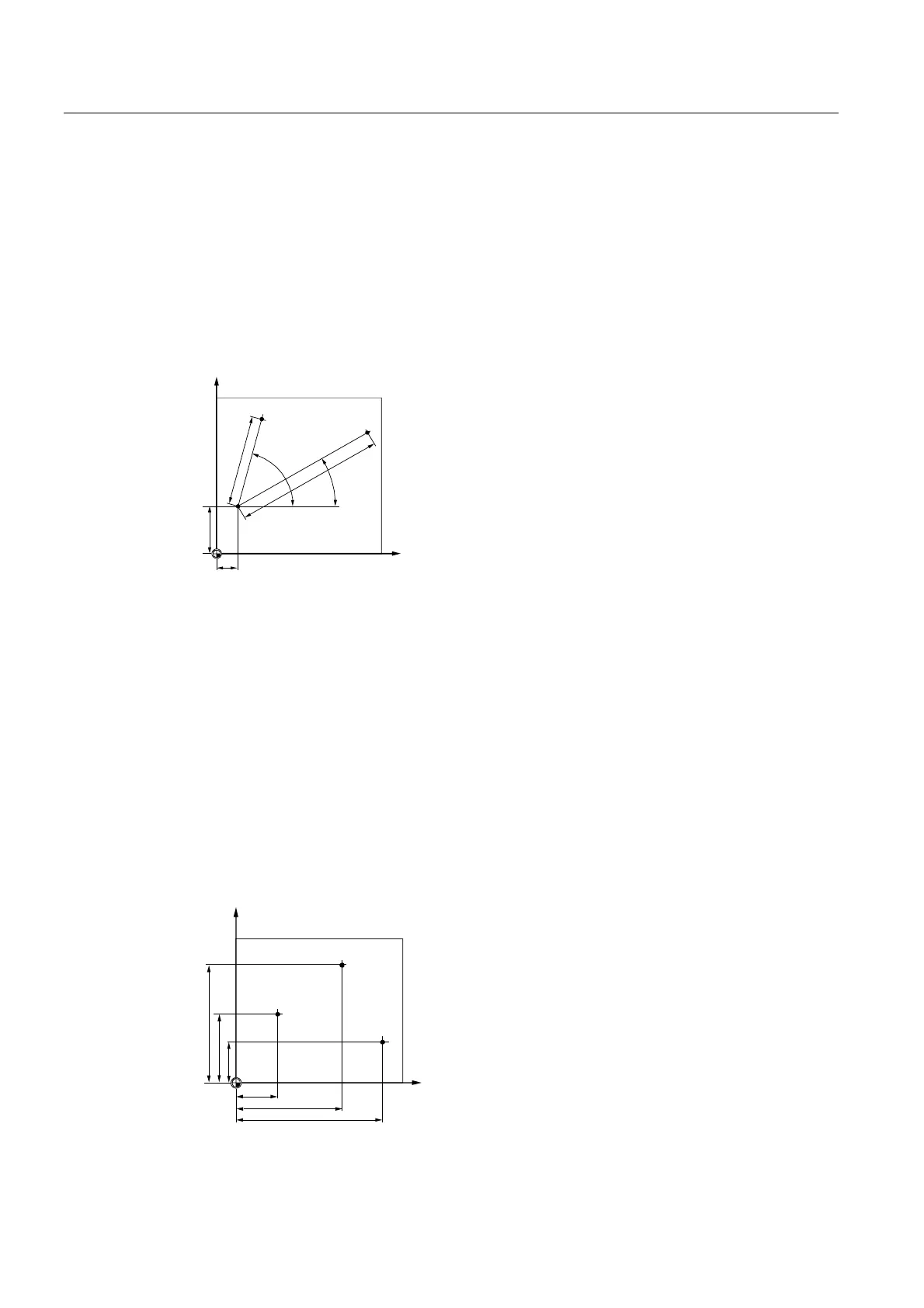

7.3.2 Polar coordinates

The rectangular coordinate system is suitable in cases where dimensions in the production

drawing are orthogonal. For workpieces dimensioned with arcs or angles, it is better to

define positions using polar coordinates. This is possible if you are programming a straight

line or a circle.

Polar coordinates have their zero point at the "pole".

Example

3RO

r

r

3

3

<

;

Points P1 and P2 can then be described – with reference to the pole – as follows:

P1:Radius =100 / angle =30°

P2:Radius =60 / angle =75°

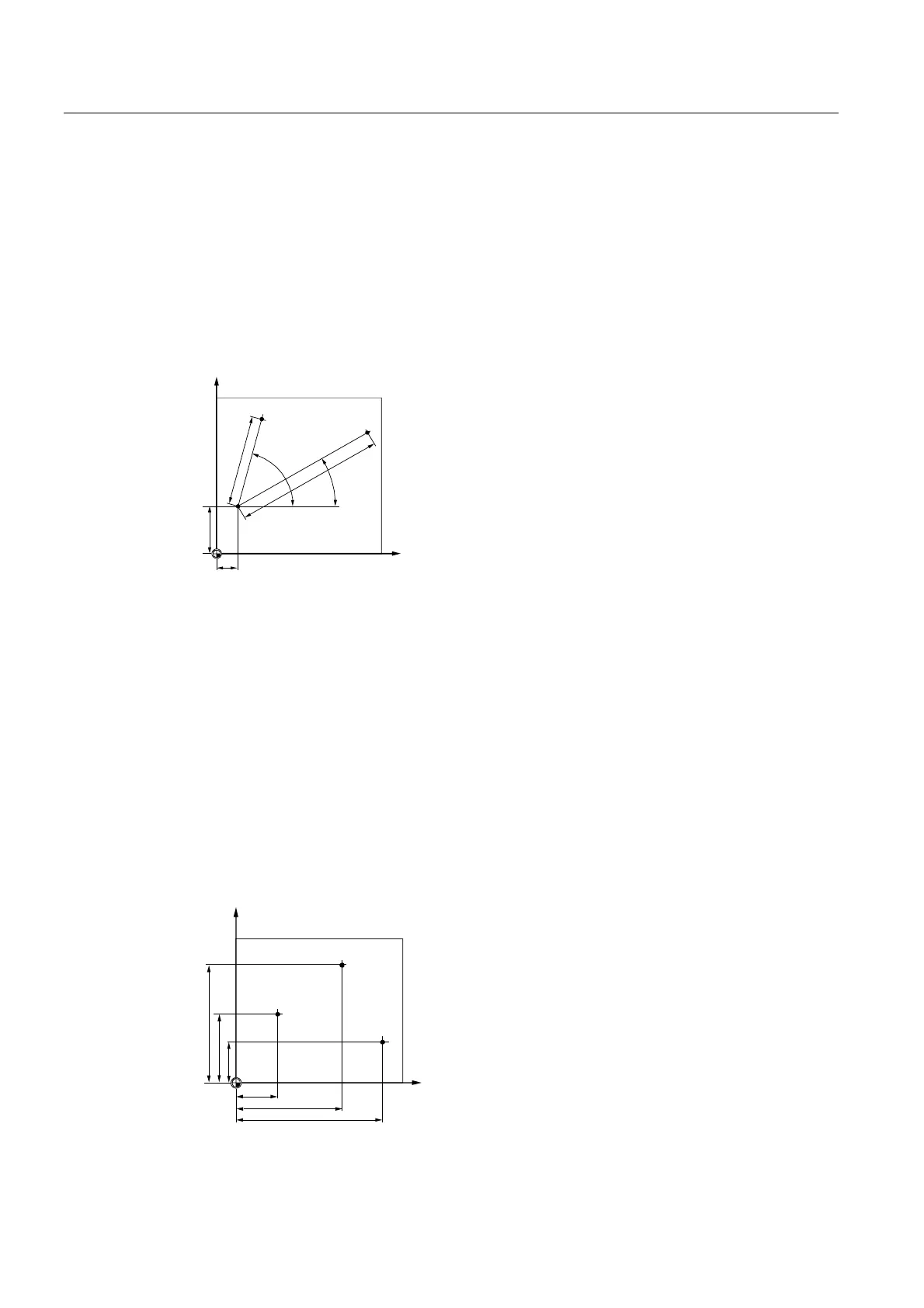

7.3.3 Absolute and incremental dimensions

Absolute dimensions

With absolute dimensions, all the position specifications refer to the currently valid zero

point. Applied to tool movement this means: The absolute dimension data defines the

position, to which the tool is to travel.

Example

3

3

3

<

;

Loading...

Loading...