Setting up the machine

2.6 Measuring the workpiece zero

Milling

Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

83

Automatic measurement

1. Prepare the measurement (see steps 1 to 6 above).

2. Approach measuring point P1 with the workpiece probe and press the

<CYCLE START> key.

This starts the automatic measuring process. The position of

measuring point 1 is measured and stored.

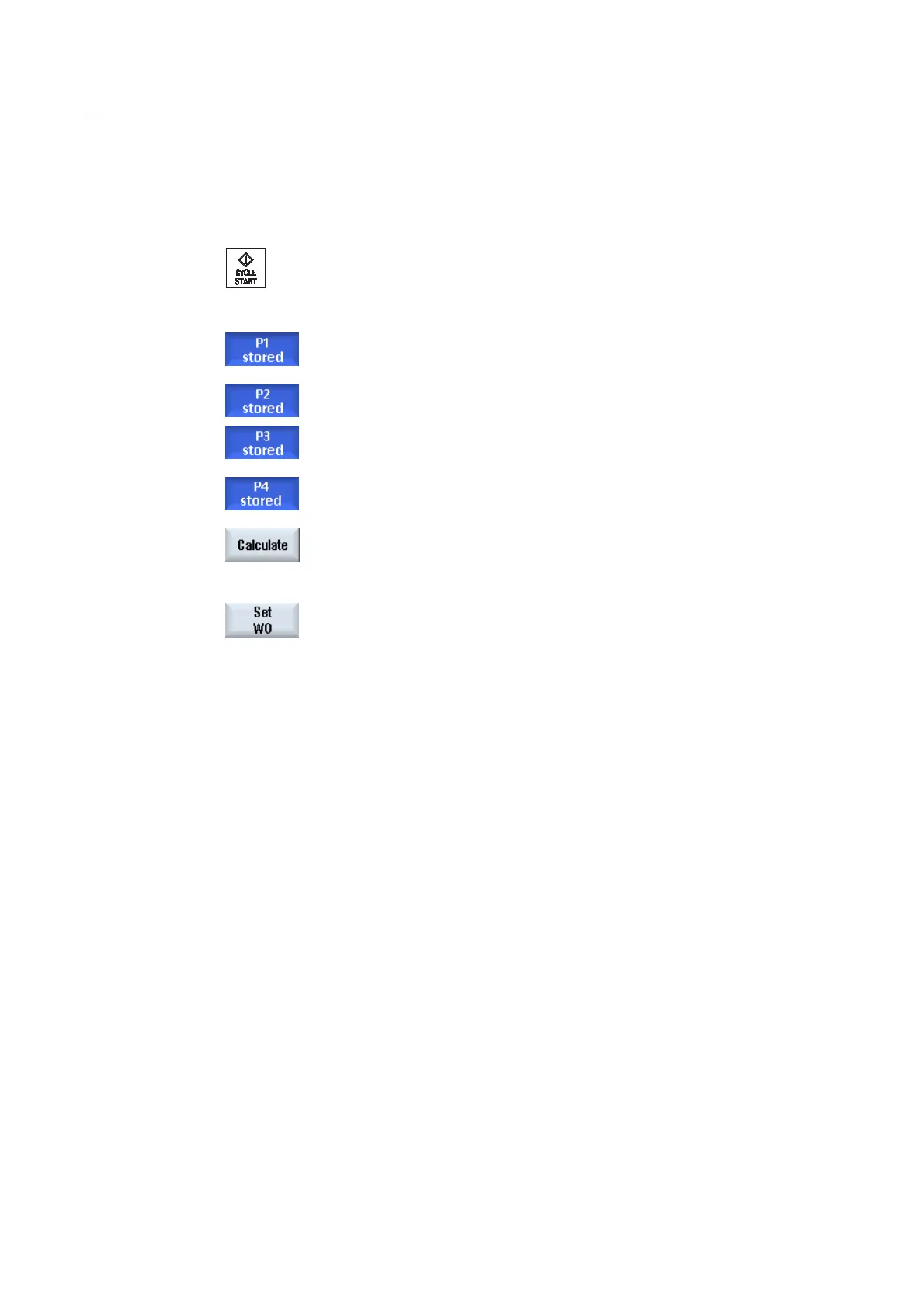

The "P1 stored" softkey becomes active.

3. Repeat the operation to measure and store points P2 and P3.

If you are measuring a corner not equal to 90°, repeat the procedure

to measure and store point P4.

4. Press the "Calculate" softkey.

The corner point and angle α are calculated and displayed.

- OR -

Press the "Set WO" softkey.

The corner point now corresponds to the setpoint position. The

calculated offset is stored in the offset target that you have selected.

2.6.8 Measuring a pocket and hole

You can measure rectangular pockets and one or more holes and then align the workpiece.

Measuring a rectangular pocket

The rectangular pocket must be aligned at right-angles to the coordinate system. By

automatically measuring 4 points inside the pocket, its length, width and center point can be

determined.

Measuring 1 hole

The workpiece with the hole to be measured is clamped to the work table in any position. In

the hole, 4 points are automatically measured, and from this measurement, the diameter and

center point of the hole are determined.

Measuring 2 holes

The workpiece with the two holes to be measured is clamped to the work table in any

position. 4 points are automatically measured in both holes and the hole centers are

calculated from them. Angle α is calculated from the connecting line between both center

points and the reference axis, and the new zero point that corresponds to the center point of

the 1st hole is determined.

Loading...

Loading...