Programming technological functions (cycles)

8.3 Contour milling

Milling

Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

347

8.3.10 Milling contour pocket (CYCLE63)

Function

Before you can machine a pocket with islands, you must enter the contour of the pocket and

islands. The first contour you specify is interpreted as the pocket contour and all the others

as islands.

From the programmed contours and the input screen form for stock removal, the cycle

generates a program that removes the pockets with islands from inside to outside in parallel

to the contour.

The islands can also be located partially outside the pocket or overlap each other.

Procedure

1. The part program or ShopMill program to be processed has been

created and you are in the editor.

2. Press the "Contour milling" and "Pocket" softkeys.

The "Mill pocket" input window opens.

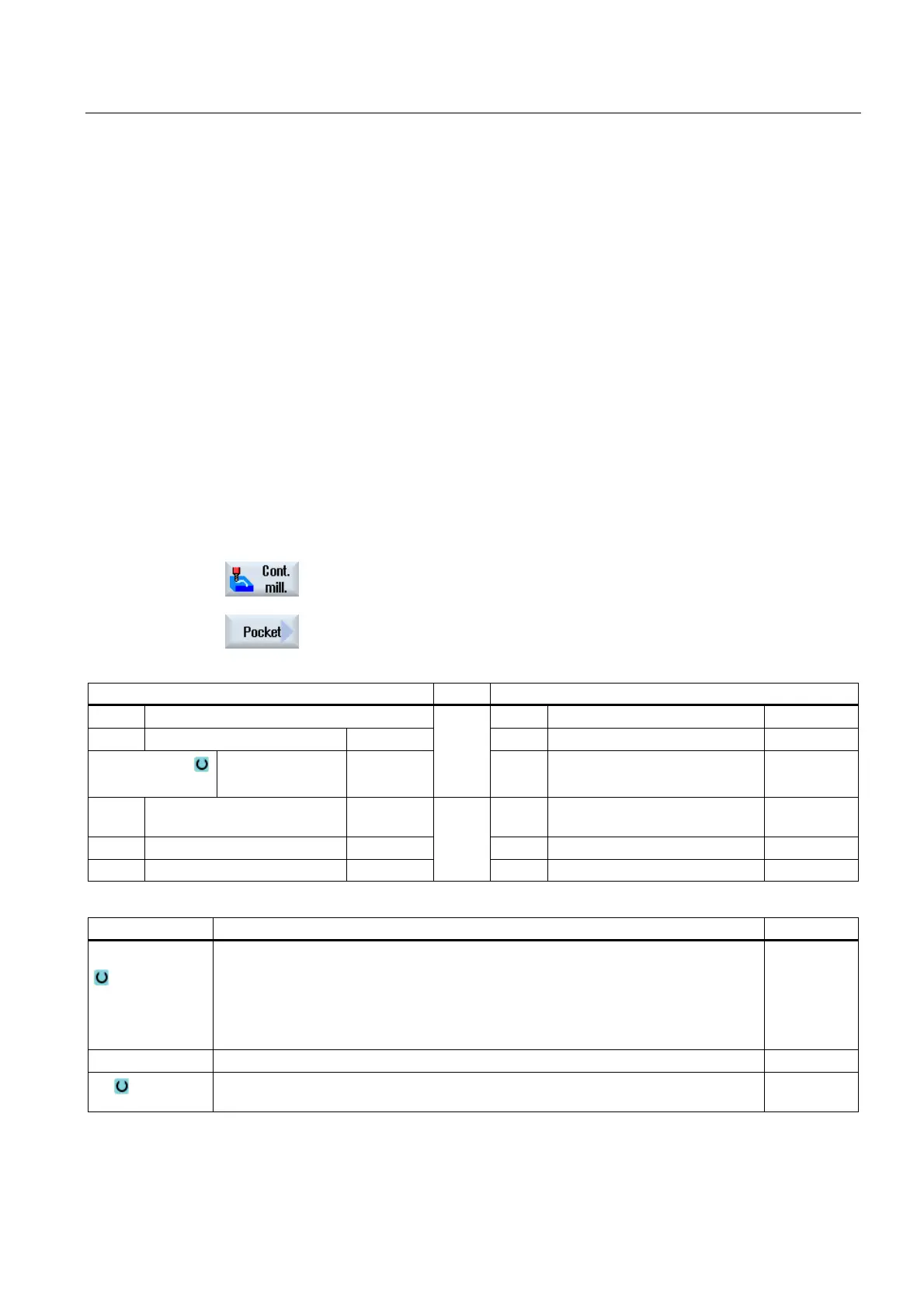

Parameters, G code program Parameters, ShopMill program

PRG Name of the program to be generated T Tool name

PL Machining plane D Cutting edge number

Milling direction

Climbing

Conventional

F Feedrate mm/min

mm/rev

RP Retraction plane mm S / V Spindle speed or constant

cutting rate

rpm

m/min

SC Safety clearance mm

F Feedrate mm/min

Parameter Description Unit

Machining

The following machining operations can be selected:

∇ (roughing)

∇∇∇ base (base finishing)

∇∇∇ edge (edge finishing)

Chamfering

Z0 Reference point Z mm

Z1 Pocket depth (abs) or depth relative to Z0 (inc)

- (only for ∇, ∇∇∇ base or ∇∇∇ edge)

mm

Loading...

Loading...