Programming technological functions (cycles)

8.2 Milling

Milling

Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

303

Parameter Description Unit

X0

Y0

Z0

The positions refer to the reference point:

Reference point X – (for single position only)

Reference point Y – (for single position only)

Reference point Z – (for single position only)

mm

mm

mm

∅ Diameter of spigot mm

L Length of spigot mm

R Corner radius mm

α0 Angle of rotation Degrees

Z1 Spigot depth (abs) or depth relative to Z0 (inc) - (only for ∇ and ∇∇∇) mm

DZ Maximum depth infeed - (only for ∇ and ∇∇∇) mm

UXY Plane finishing allowance for the length (L) and width (W) of the circular spigot.

Smaller circular spigot dimensions are obtained by calling the cycle again and

programming it with a lower finishing allowance. - (only for ∇ and ∇∇∇)

mm

UZ Depth finishing allowance (tool axis) - (only for ∇ and ∇∇∇) mm

∅1 Diameter of blank spigot (important for determining approach position) - (only for ∇ and

∇∇∇)

mm

FS Chamfer width for chamfering - (for chamfering only) mm

ZFS Insertion depth of tool tip (abs or inc) - (for chamfering only) mm

8.2.6 Multi-edge (CYCLE79)

Function

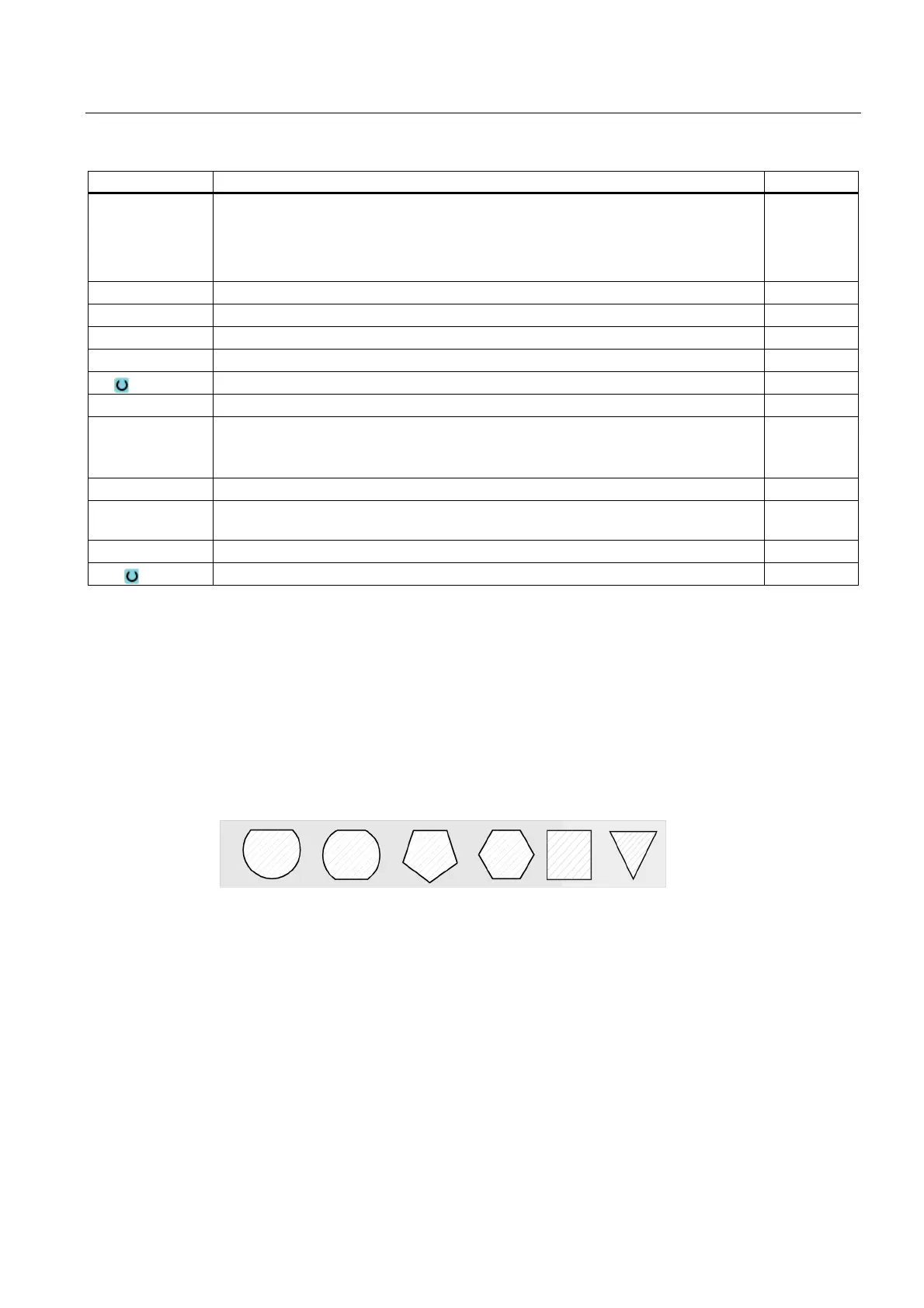

You can mill a multi-edge with any number of edges with the "Multi-edge" cycle.

You can select from the following shapes with or without a corner radius or chamfer:

Approach/retraction

1. The tool approaches the starting point at rapid traverse at the height of the retraction

plane and is fed in to the safety clearance.

2. The tool traverses the multi-edge in a quadrant at machining feedrate. The tool first

executes infeed at machining depth and then moves in the plane. The multi-edge is

machined depending on the programmed machining direction (up-cut/down-cut) in a

clockwise or counterclockwise direction.

3. When the first plane has been machined, the tool retracts from the contour in a quadrant

and then infeed to the next machining depth is performed.

Loading...

Loading...