Programming technological functions (cycles)

8.2 Milling

Milling

300 Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

Procedure

1. The part program or ShopMill program to be processed has been

created and you are in the editor.

2. Press the "Milling" softkey.

3. Press the "Multi-edge spigot" and "Rectangular spigot" softkeys.

The "Rectangular Spigot" input window opens.

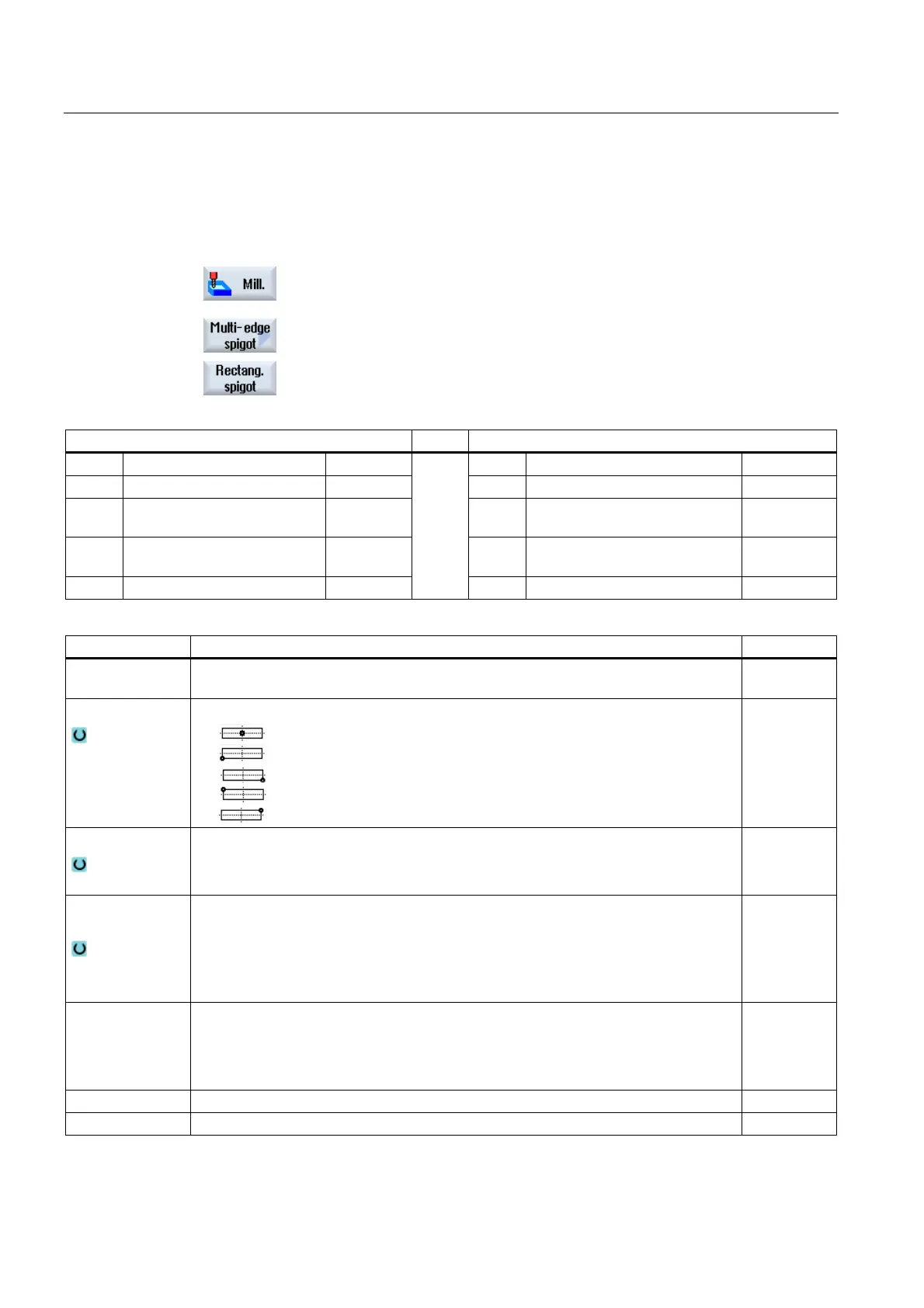

Parameters, G code program Parameters, ShopMill program

PL Machining plane T Tool name

Milling direction D Cutting edge number

RP Retraction plane mm (in) F Feedrate mm/min

mm/rev

SC Safety clearance mm S / V Spindle speed or constant

cutting rate

rpm

m/min

F Feedrate mm/min

Parameter Description Unit

FZ

(only for G code)

Depth infeed rate mm/min

Reference point

The following different reference point positions can be selected:

(center)

(bottom left)

(bottom right)

(top left)

(top right)

Machining

∇ (roughing)

∇∇∇ (finishing)

Chamfering

Machining

position

Single position

A rectangular spigot is machined at the programmed position (X0, Y0, Z0).

Position pattern

Several rectangular spigots are machined in a position pattern

(e.g. full circle, pitch circle, grid, etc.).

X0

Y0

Z0

The positions refer to the reference point:

Reference point X – (for single position only)

Reference point Y – (for single position only)

Reference point Z – (for single position only)

mm

mm

mm

W Width of spigot mm

L Length of spigot mm

Loading...

Loading...