Programming technological functions (cycles)

8.2 Milling

Milling

310 Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

Procedure

1. The part program or ShopMill program to be processed has been

created and you are in the editor.

2. Press the "Milling" softkey.

3. Press the "Groove" and "Circumferential groove" softkeys.

The "Circumferential Groove" input window opens.

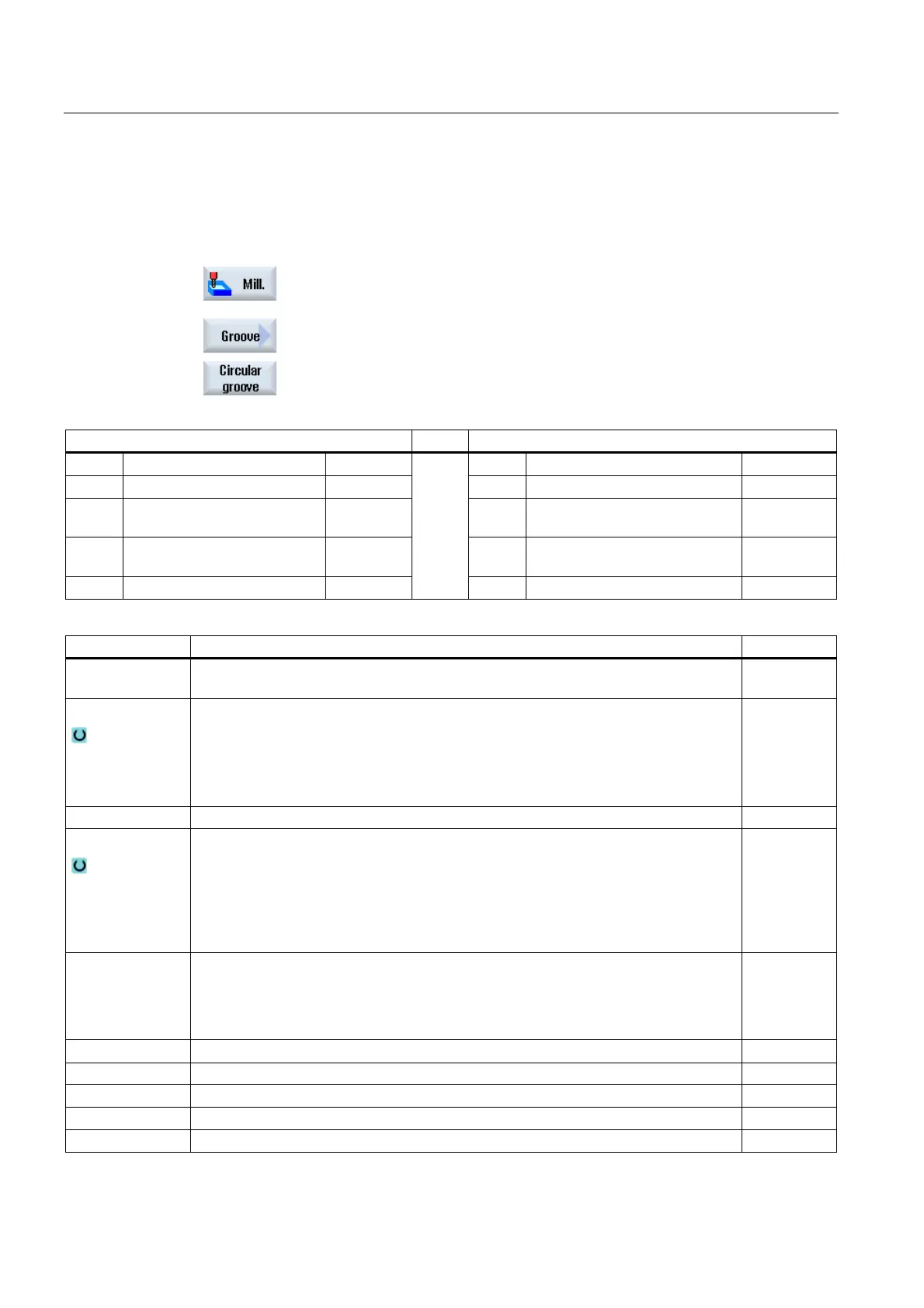

Parameters, G code program Parameters, ShopMill program

PL Machining plane T Tool name

Milling direction D Cutting edge number

RP Retraction plane mm F Feedrate mm/min

mm/rev

SC Safety clearance mm S / V Spindle speed or constant

cutting rate

rpm

m/min

F Feedrate mm/min

Parameter Description Unit

FZ

(only for G code)

Depth infeed rate mm/min

in/tooth

Machining

∇ (roughing)

∇∇∇ (finishing)

∇ + ∇∇∇ (roughing and finishing) - (only for ShopMill)

∇∇∇ edge (edge finishing) - (only for G code)

Chamfering

FZ Depth infeed rate - (only for ∇ and ∇∇∇) mm/min

Circular pattern

Full circle

The circumferential grooves are positioned around a full circle. The groove spacing

is uniform and is calculated by the controller.

Pitch circle

The circumferential grooves are positioned around a pitch circle. The groove

spacing can be determined on the basis of angle α2.

X0

Y0

Z0

The positions refer to the center point:

Reference point X

Reference point Y

Reference point Z

mm

mm

mm

N Number of grooves

R Radius of circumferential groove mm

α0 Starting angle Degrees

α1 Opening angle of the groove Degrees

α2 Advance angle - (for pitch circle only) Degrees

Loading...

Loading...