Programming technological functions (cycles)

8.3 Contour milling

Milling

350 Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

Procedure

1. The part program or ShopMill program to be processed has been

created and you are in the editor.

2. Press the "Contour milling" and "Pocket Res. Mat." softkeys.

The "Pocket Res. Mat." input window opens.

3. For the ShopMill program, press the "All parameters" softkey if you

want to enter additional parameters.

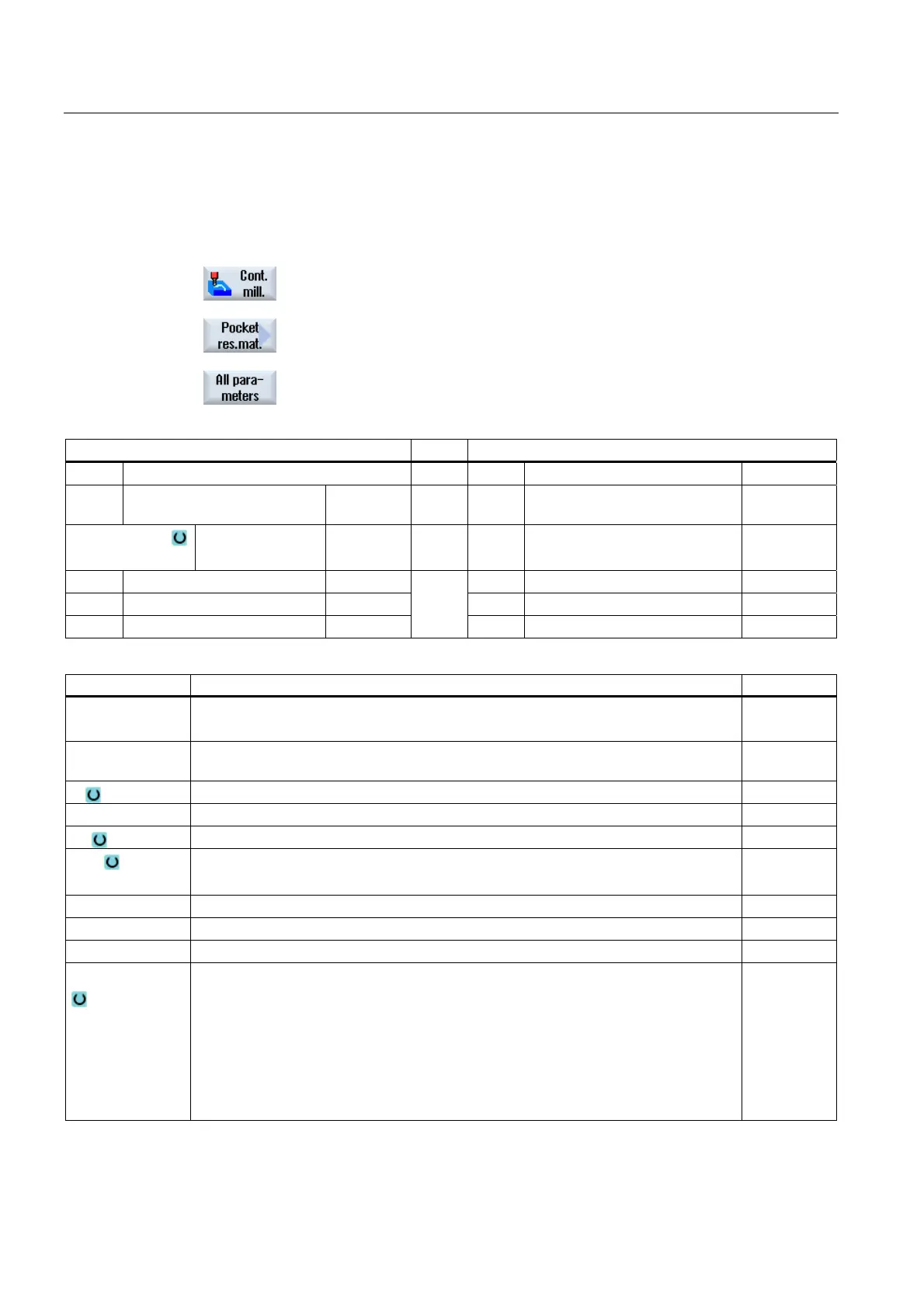

Parameters, G code program Parameters, ShopMill program

PRG Name of the program to be generated T Tool name

PL Machining plane F Feedrate mm/min

mm/rev

Milling direction

Climbing

Conventional

S / V Spindle speed or constant cutting

rate

rpm

m/min

RP Retraction plane mm

SC Safety clearance mm

F Feedrate mm/min

Parameter Description Unit

Machining The following machining operations can be selected:

∇ (roughing)

TR Reference tool Tool, which is used in the "solid machining" machining step. This is

used to determine the residual corners.

D Cutting edge number

Z0 Reference point mm

Z1 Pocket depth (abs) or depth referred to Z0 (inc) mm

DXY

Maximum plane infeed

Maximum plane infeed as a percentage of the milling cutter diameter

mm

%

DZ Maximum depth infeed mm

UXY Finishing allowance, plane mm

UZ Finishing allowance, depth mm

Lift mode

Lift mode before new infeed

If the machining operation requires several points of insertion, the retraction height can

be programmed:

to RP

Z0 + safety clearance

When making the transition to the next insertion point, the tool returns to this height. If

there are no elements larger than Z0 in the pocket area, "Z0 + safety clearance" can be

selected as the lift mode.

mm

mm

Loading...

Loading...