Programming technological functions (cycles)

8.3 Contour milling

Milling

354 Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

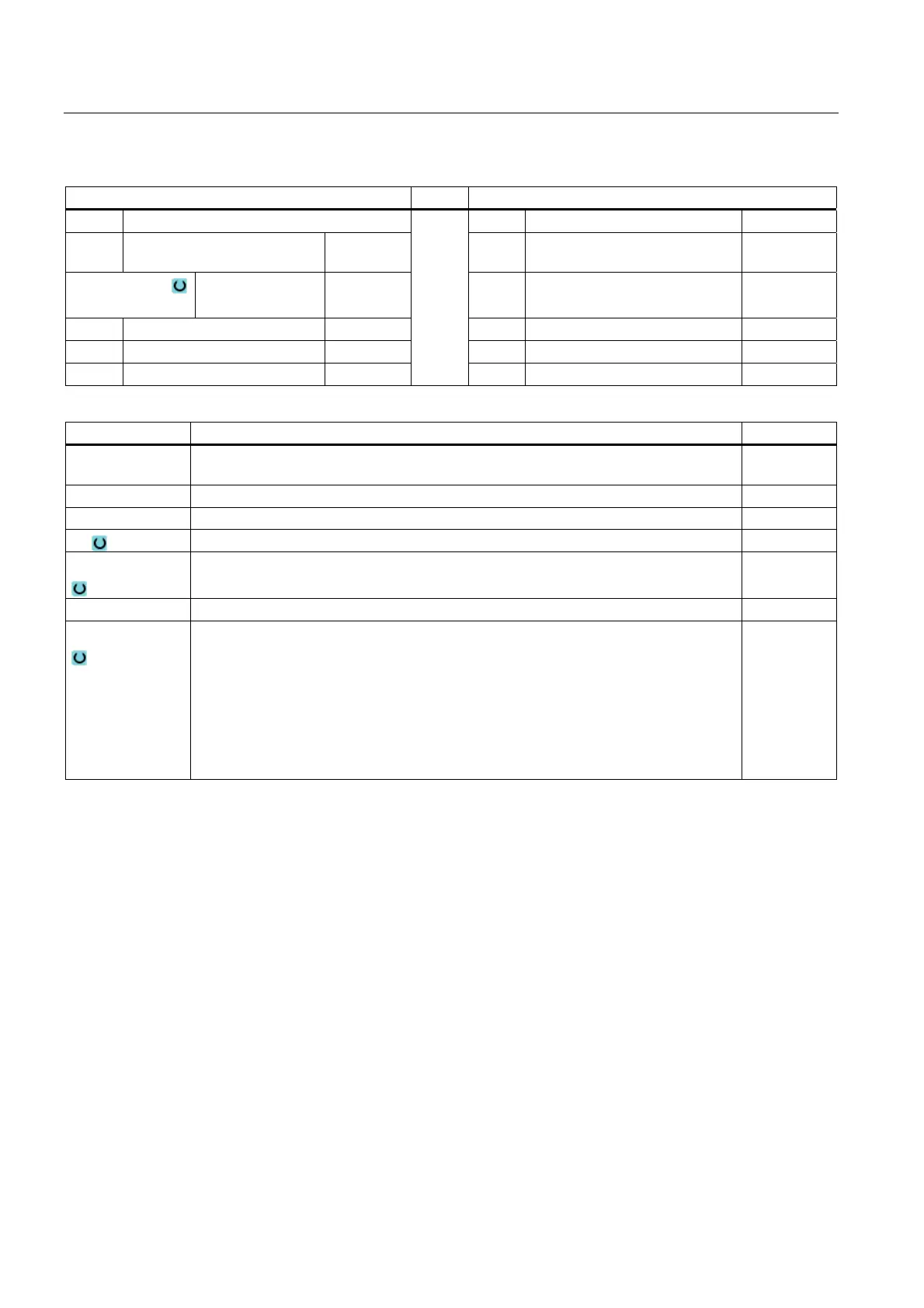

Parameters, G code program Parameters, ShopMill program

PRG Name of the program to be generated T Tool name

PL Machining plane F Feedrate mm/min

mm/rev

Milling direction

Climbing

Conventional

S / V Spindle speed or constant

cutting rate

rpm

m/min

RP Retraction plane mm

SC Safety clearance mm

F Feedrate mm/min

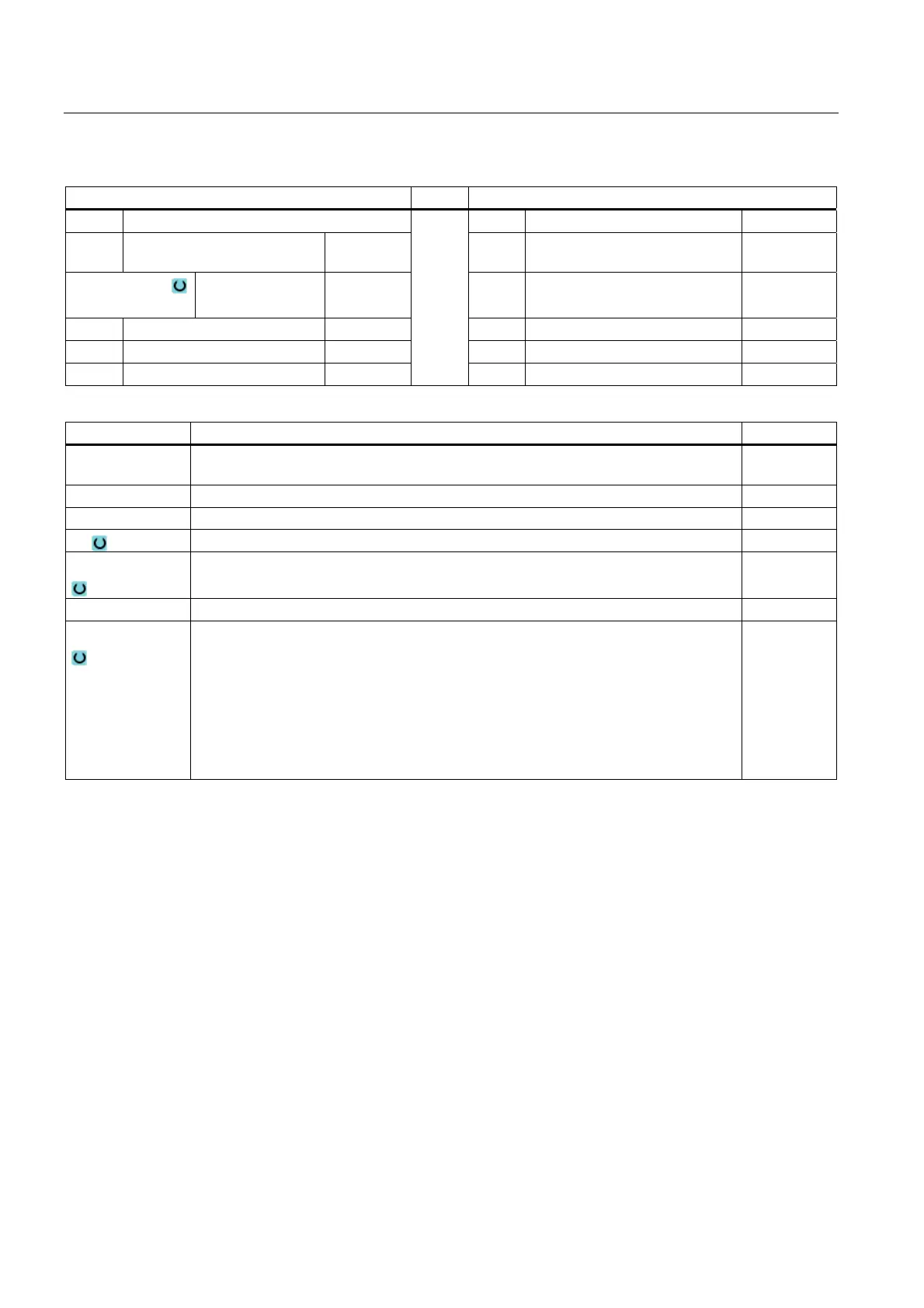

Parameter Description Unit

TR Reference tool Tool, which is used in the "solid machining" machining step. This is

used to determine the residual corners.

D Cutting edge number

Z0 Reference point Z mm

Z1 Pocket depth (abs) or depth referred to Z0 (inc) mm

DXY

Maximum plane infeed

Maximum plane infeed as a percentage of the milling cutter diameter

mm

%

DZ Maximum depth infeed mm

Lift mode

Lift mode before new infeed

If the machining operation requires several points of insertion, the retraction height can

be programmed:

To retraction plane

Z0 + safety clearance

When making the transition to the next insertion point, the tool returns to this height. If

there are no elements larger than Z0 in the pocket area, "Z0 + safety clearance" can be

selected as the lift mode.

mm

mm

Loading...

Loading...