Programming technological functions (cycles)

8.5 Contour turning - only for G code programs

Milling

Operating Manual, 03/2010, 6FC5398-7CP20-1BA0

399

Procedure

1. The part program to be executed has been created and you are in the

editor.

2. Press the "Turning" and "Contour turning" softkeys.

3. Press the "Grooving residual material" softkey.

The "Grooving residual material" input window is opened.

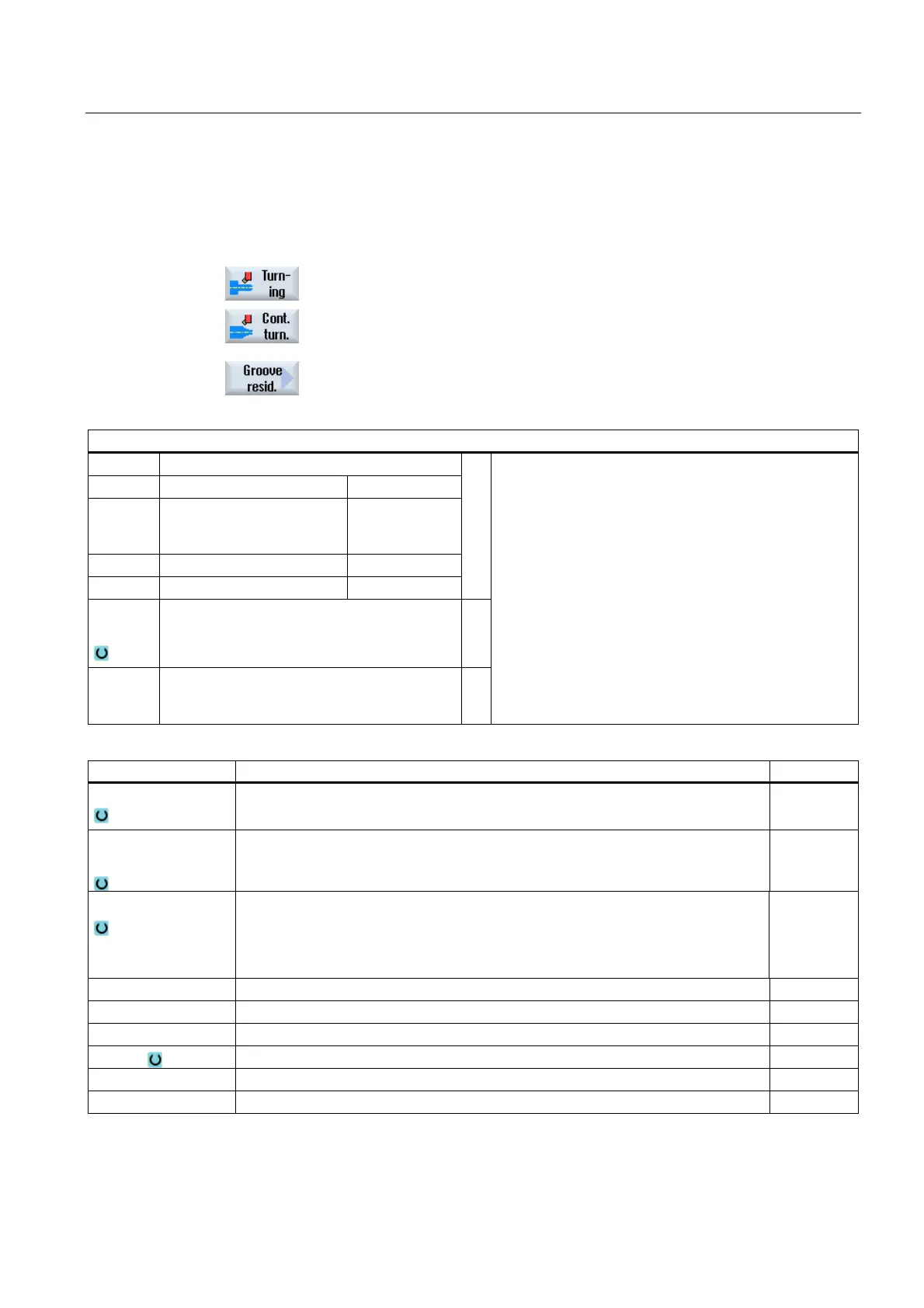

Parameters, G code program

PRG Name of the program to be generated

PL Machining plane

RP Retraction plane - (only for

longitudinal machining

direction)

mm

SC Safety clearance mm

F Feedrate mm/min

Residual

material

With subsequent residual material removal

Yes

No

CONR Name to save the updated unmachined-part

contour for residual material removal - (only

"Yes" for residual material removal)

Parameters Description Unit

Machining

∇ (roughing)

∇∇∇ (finishing)

Machining

direction

Face

Longitudinal

Position

front

back

internal

external

D Maximum depth infeed - (only for ∇) mm

XDA 1. Grooving limit tool (abs) – (only for face machining direction) mm

XDB 2. Grooving limit tool (abs) – (only for face machining direction) mm

UX or U Finishing allowance in X or finishing allowance in X and Z – (only for ∇) mm

UZ Finishing allowance in Z – (only for UX) mm

DI For zero: Continuous cut - (only for ∇) mm

Loading...

Loading...