1 689 989 067 2017-12-08| Robert Bosch GmbH

46 | EPS 708 | Operationen

4.5 Clamping the common rail pump

! Always observe the tightening torques of fastening

parts and coupling halves (see sec. 8, Tightening

torques).

! The T-bar (special accessory) used to manually

rotate the flywheel (fig. 8, pos. 1) must not be left

inserted in the locating holes of the flywheel.

! The drive coupling (fig. 8, pos. 2) is a safety

component of the EPS 708. The drive coupling may

therefore only be repaired by the responsible Bosch

Customer Service.

! During all assembly work, such as clamping/

removing common rail pumps and common rail

injectors, the protective hood of the EPS 708 must

always be opened as far as it will go.

! Only use the specified clamping devices and drive

couplings for clamping common rail pumps on the

EPS 708.

! Before mounting the common rail pump to the

EPS 708, check actuators (EAV, DRV, DMV or ZME)

for short-circuited turns. If the resistance between

the connection pin and the housing is lower than

50Ohm, then the defective actuator must be

replaced before mounting to the EPS 708.

! Before clamping a common rail pump on the

EPS 708, check the pump housing for cracks and

the freedom of movement of the pump drive shaft.

Common rail pumps with a stiff or jammed drive

shaft or with a cracked housing must not to be

clamped or tested.

! Before fitting the drive flange, lubricate the radial

shaft oil seal of the common rail pump with engine

oil 15W-40. The common rail pump is only to be

operated with a lubricated radial shaft oil seal.

i When testing common rail pumps without a

lubricating oil supply, the lubricating oil supply and

return pipes (fig. 2, pos. 1 and 2) must be sealed

with dummy plugs.

i All clamping components and couplings required for

clamping are contained in the special accessories

catalog for EFEP/EPS (part number 1689980289)

or on the ToolsCATAlogue special accessories CD.

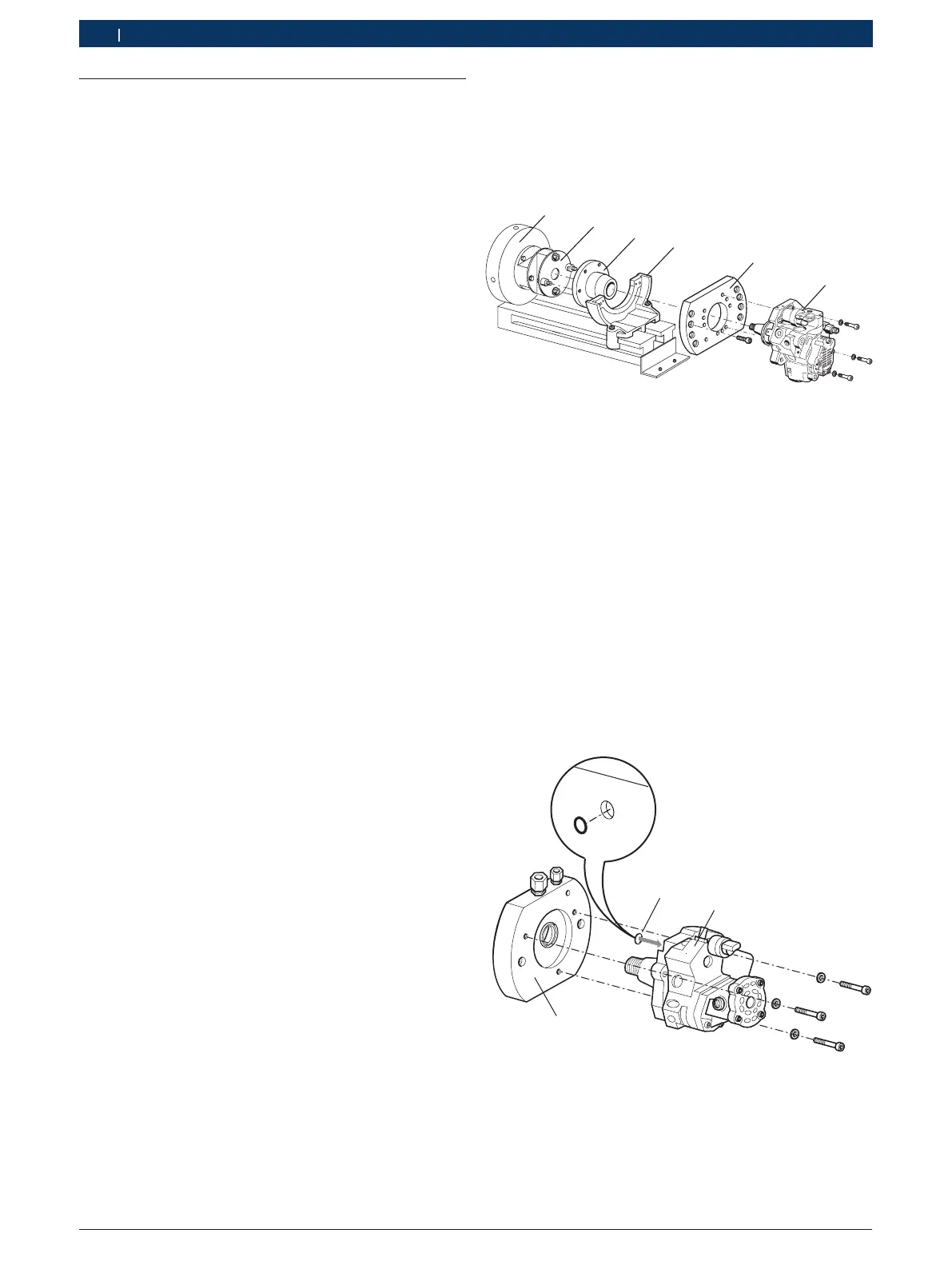

4.5.1 Common rail pump

with tapered shaft connection

i Special accessories are required for clamping the

common rail pump.

458846-05_Ko

2

3

4

5

6

Fig. 8: Common rail pump with tapered shaft connection

1 Flywheel

1)

2 Drive coupling

1)

3 Pump-specific drive flange

3)

4 Clamping bracket

2)

5 Pump-specific clamping flange

3

)

6 Common rail pump

1)

Included with the EPS 708

2)

Special accessory

3)

Included with set of accessories

1. Secure the drive coupling 1 686 401 024 (fig.8,

pos.2) to the flywheel (fig. 8, pos. 1) of the

EPS 708. The tightening torque of the bolts is

95 ±2 Nm.

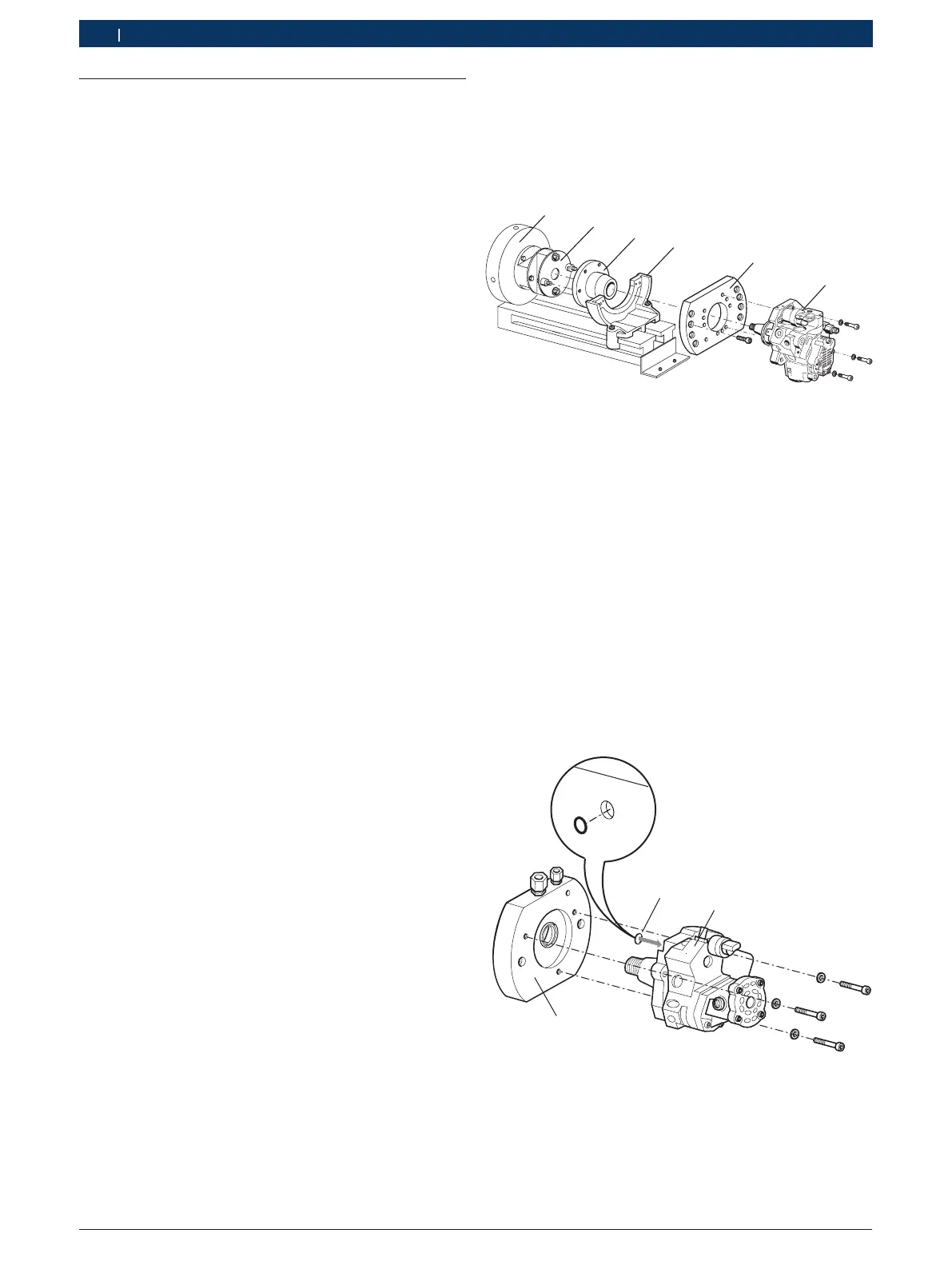

2. In the CP 3.4 with lubricating oil supply, insert the

O-ring Ø10 x 3 mm (fig. 9, pos. 1) in the lubricating

oil supply hole of the common rail pump.

458800-12_ko

1

2

3

Fig. 9: Common rail pump with tapered shaft connection

1 O-ring

2 Common rail pump

3 Clamping flange

Loading...

Loading...