1 689 989 067 2017-12-08| Robert Bosch GmbH

Maintenance | EPS 708 | 59 en

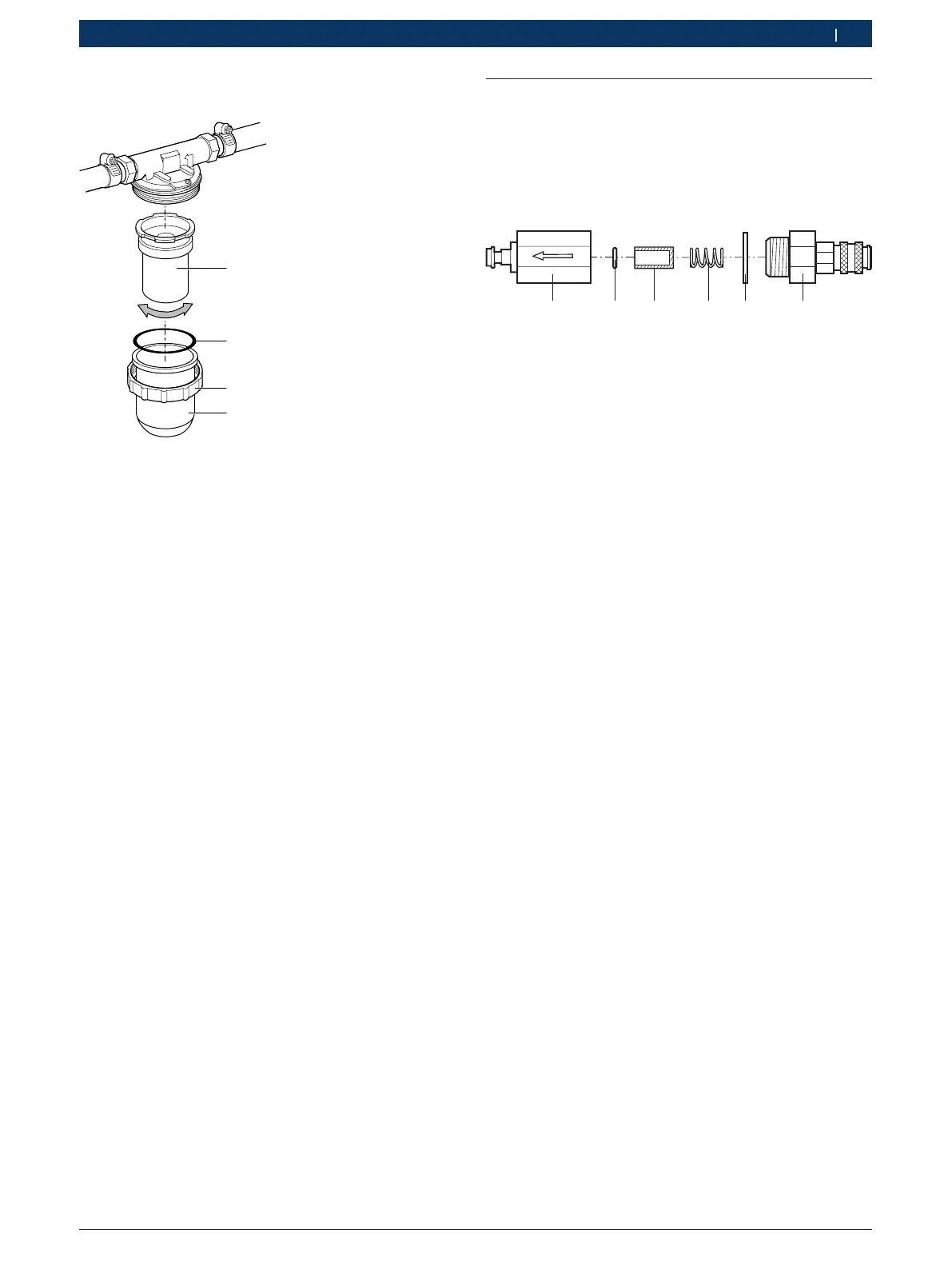

6.8.2 Replacing the flow meter filter element

1

2

3

4

458846-16_Ko

Fig. 24: Flow meter filter

1 Filter element

2 O-ring

3 Union nut

4 Filter housing

1. Unscrew union nut (fig. 24, item 3) and remove it

along with filter housing (fig. 24, item 4).

2. Remove O-ring (fig. 24, item 2).

3. Detach filter element (fig. 24, item 1) clockwise and

remove it.

4. Dispose of O-ring (fig. 24, item 2) and filter element

(fig. 24, item 1).

5. Insert new filter element and tighten it

counterclockwise.

i Make sure the sealing surfaces and the O-ring are

clean during installation.

6. Attach filter housing with new O-ring. Hand-tighten

union nut. Do not use force.

" The filter element has been replaced.

6.8.3 Changing the pump return filter element

¶ For filter change, see section 6.8.2.

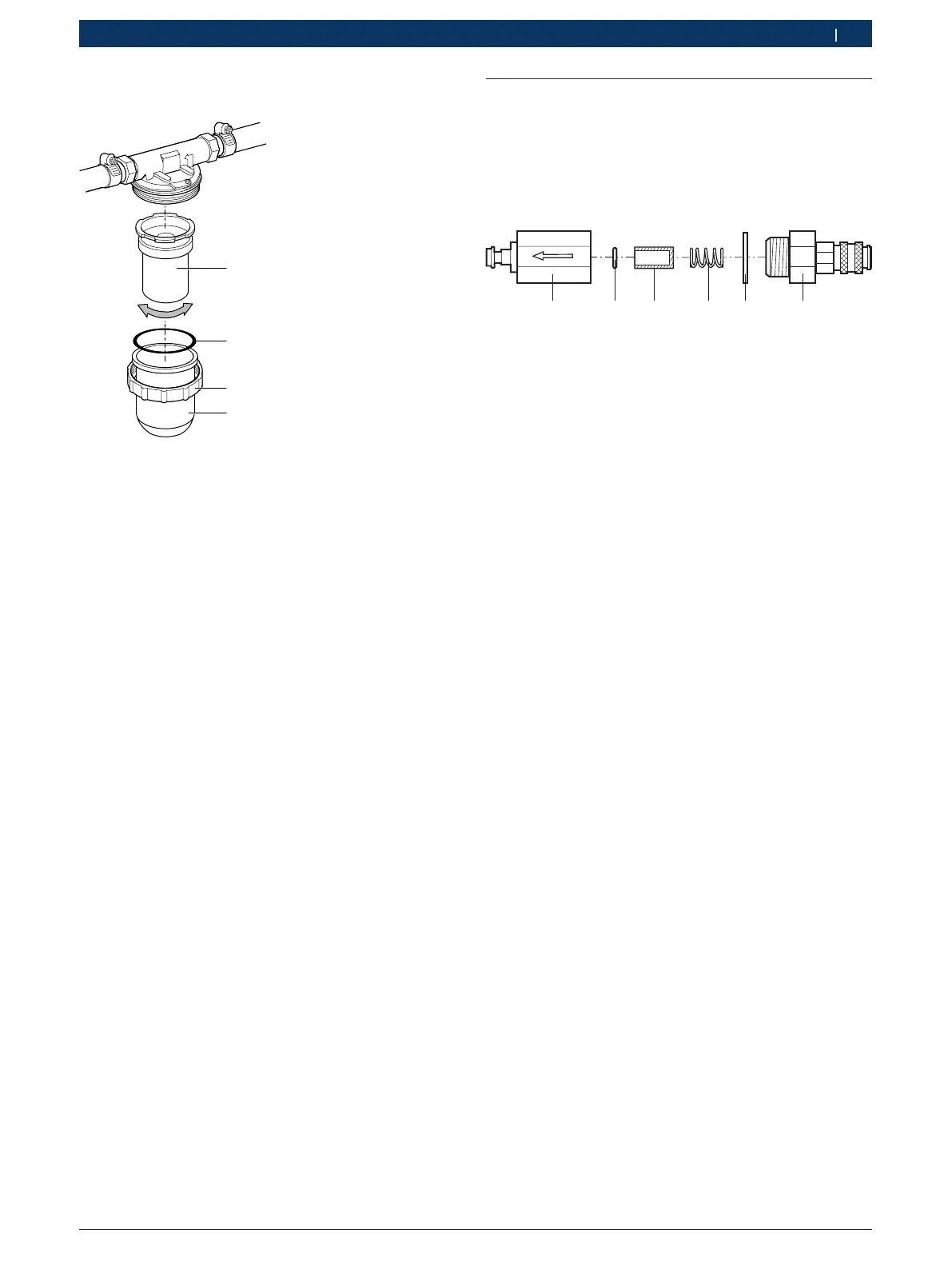

6.9 Replacing the inlet filter cartridge

(e.g. Injector A)

i The sediments in the inlet filters are mainly

attributable to not or insufficiently cleaned common

rail injectors before testing.

Fig. 25: Replacing the filter cartridge

1 Threaded joint

2 Flat seal

3 Spring

4 Filter cartridge

5 O-ring

6 Threaded joint

1. Detach the inlet filter from the quick-release

couplings.

2. Using two wrenches, slacken and completely

unscrew the threaded joints (fig.25, pos. 1 and 6).

3. Take out the flat seal, spring, filter cartridge and

O-ring (fig. 25, pos. 2, 3, 4, 5).

4. Remove and dispose of the flat seal, filter cartridge

and O-ring.

5. Clean both threaded joints with clean calibrating oil.

6. Insert a new O-ring.

7. Insert a new filter cartridge, ensuring the correct

position.

8. Put on a new flat seal.

9. Insert the spring.

10. Screw the threaded joints together and tighten with

the torque wrench (tightening torque = 50Nm).

" The filter cartridge is now changed.

! The inlet filters must always be inserted in the

injected fuel quantity inlets A to F (fig. 2, pos. 8)

(note the direction of flow of the inlet filters).

Never insert them in the injection chambers!

Loading...

Loading...