1 689 989 067 2017-12-08| Robert Bosch GmbH

48 | EPS 708 | Operationen

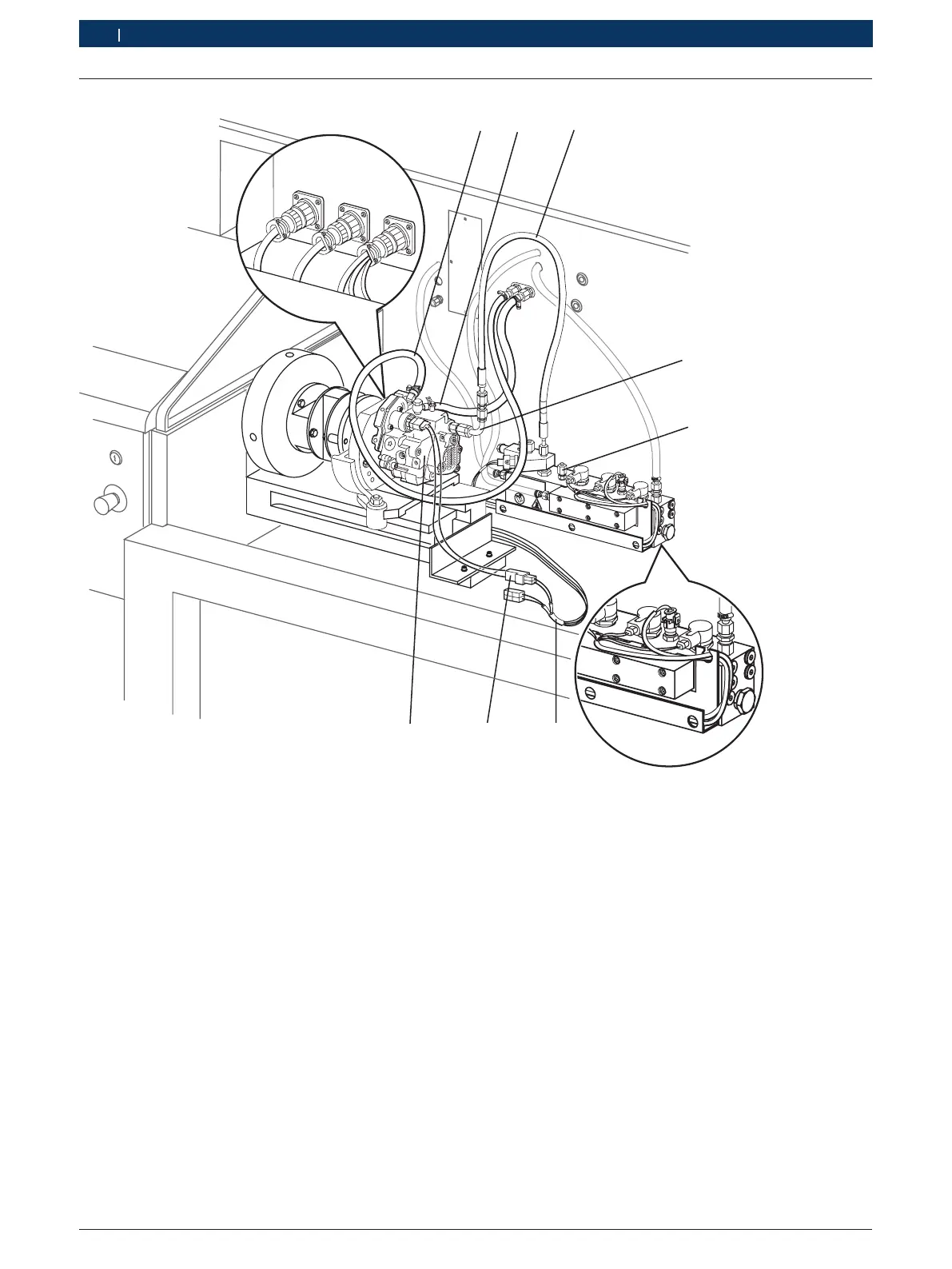

4.6 Connecting the common rail pump

Pump

over

Flow-Oil

Pump

Supply

X 24

ZME/EAV

X 25

Rail DRV

X 26

Rail Press

4

7

6

458846-12_

Ko

8

5

Fig. 11: Common rail pump connection

1 Hose (calibrating oil supply)

2 Hose (calibrating oil supply)

3 High-pressure hose

1)

1 680 712 324

4 Test pressure line

1)

1 680 750 123

5 High-pressure hose connection for CRI 846H rail

6 X24 connecting cable 1 684 463 946

7 Adapter cable

8 Common rail pump

1)

Parts set 1 687 016 064

1. Connect the hoses for the calibrating oil supply

(fig.11, pos. 1) and return (fig. 11, pos. 2) to the

connections of the common rail pump provided for

this purpose (fig. 11, pos. 8).

i For CP3.4 with the required return pressure < 10

kPa connect hose line (fig. 2, pos. 12).

i Before connecting the high-pressure hose, clean the

sealing taper and sealing cone on the high-pressure

rail and high-pressure pump.

2. Connect the high-pressure hose 1680712324 (fig. 11,

pos. 3) to the high-pressure inlet of the high-pressure

rail, and use the test pressure line 1680750123

(fig.11, pos.4) to connect to the high-pressure

connection of the common rail pump (tightening torque

= 25Nm – 30 Nm).

3. Connect X24 connecting cable 1684463946

(fig.11, item6) to X24 at EPS 708 and via the

adapter cables 1 684 460 255 or 1684460256

(fig. 11, item 7) to the electrical connection of the

common-rail pump.

4. Seal the connection for connecting the high-

pressure hose to the CRI 846H rail (fig. 11, pos. 5)

with a dummy plug.

" The common rail pump is now hydraulically and

electrically connected.

Loading...

Loading...