8. System Alignment Marathon Express

Vacuum Cassette Elevator Configuration

and Alignment

Part Number: 605914 Rev. B

Step Action

1.

VerifythatallelevatorparametersaresetcorrectlybyusingthecommandsdescribedintheVCEUser

Manual.

2.

Ensurethattherobot’sarmisretractedandtheelevatordoorisclosed,thenmovetheelevatorplat-

formtoslot1.

3.

UsingtheCDM,movetherobottotheinitialLoadLockT-axispositionusingtheMovetoStationcom-

mand.Refertotherobotmanual.

4.

EnterthehandlocatecommandontheCDM.Thiscommandwillcausetherobotservostorelease,

allowingmanualpositioningoftheendeffector.

5.

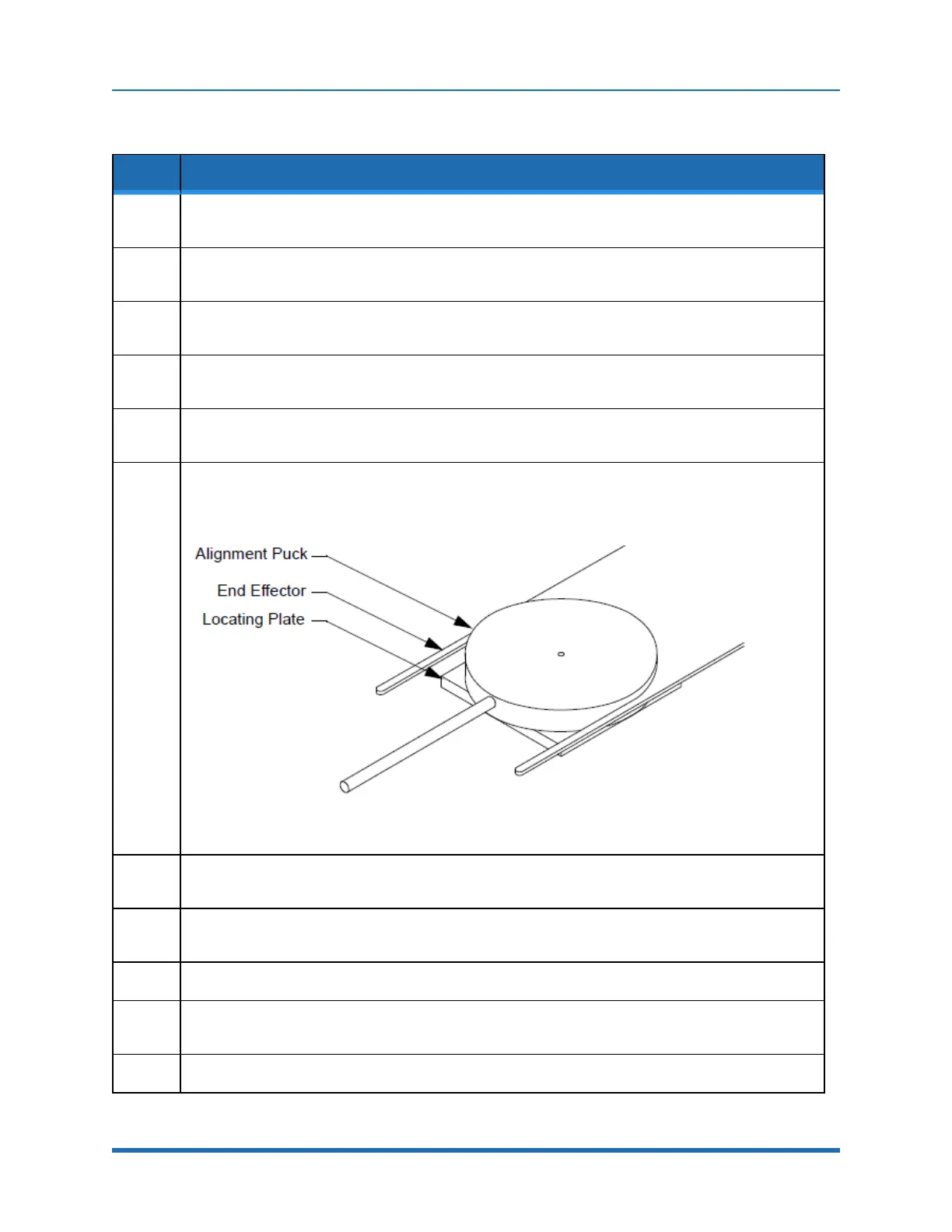

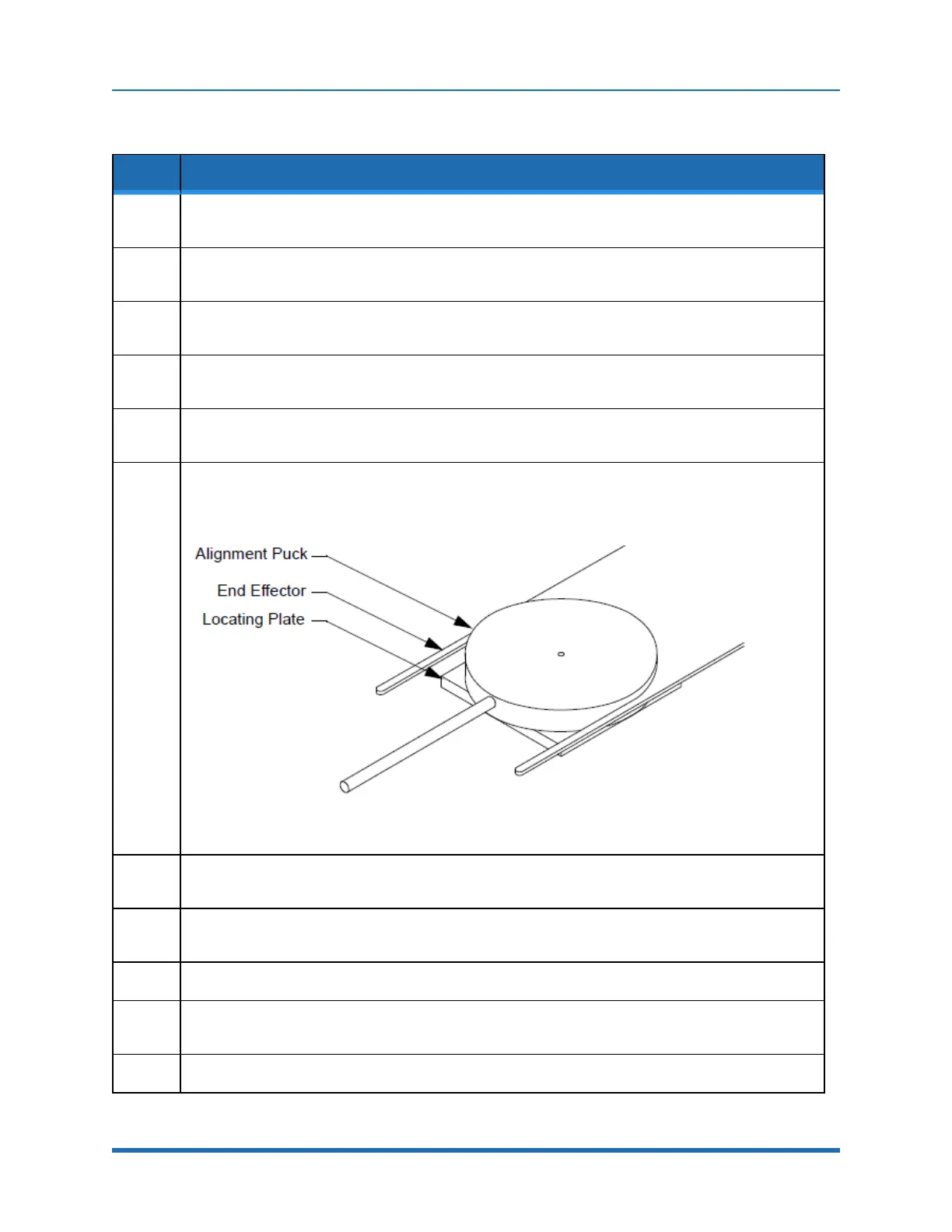

PlacetheLocatingPlateontheplatformsothatitlocksintoplace.PlacetheAlignmentPuckonthe

LocatingPlatewiththehandlepointingoutandensurethatitcanturnfreelyonthefixture.

6.

Manuallypositiontherobot’sendeffectoruntiltheU-shapedslotfitsaroundtheAlignmentPuckas

showninFigure8-3andthebottomofthe“U”iscloseto,butnottouching,thepuck(approximately

+.002inch).

Figure 8-5: Centering End Effector On Alignment Fixture

7.

OncetheendeffectorisproperlylocatedaroundthePuck,usetheCDMtoviewandrecordtheR

(radial)andT(rotational)axislocationsforthisstation.

8.

UsingtheCDM,storetheRandTaxislocations.Also,recordtheRandTvaluesintheappropriate

worksheetprovidedinAppendixC:"StationIdentification"onpage221.

9.

Retracttherobot’sarmandremovetheAlignmentPuckandLocatingPlatefromtheplatform.

10.

RecordtheStationcoordinatesintheappropriateworksheetprovidedinAppendixC:"StationIden-

tification"onpage221.

11.

RepeatforeachLoadLock.

164

Copyright © 2023, Brooks Automation, Inc.

Loading...

Loading...