The Watchlist tab contains the Watchlist resolution eld that

sets the rate at which the Watchlist triggers its update

procedure (see chapter 5.5.3 Watchlist Window). It is the

minimum interval at which the Watchlist is updated. The

update rate of each parameter in the Watchlist can only be

a multiple of the Watchlist resolution.

Illustration 5.16 Toolbox Options - Watchlist Tab

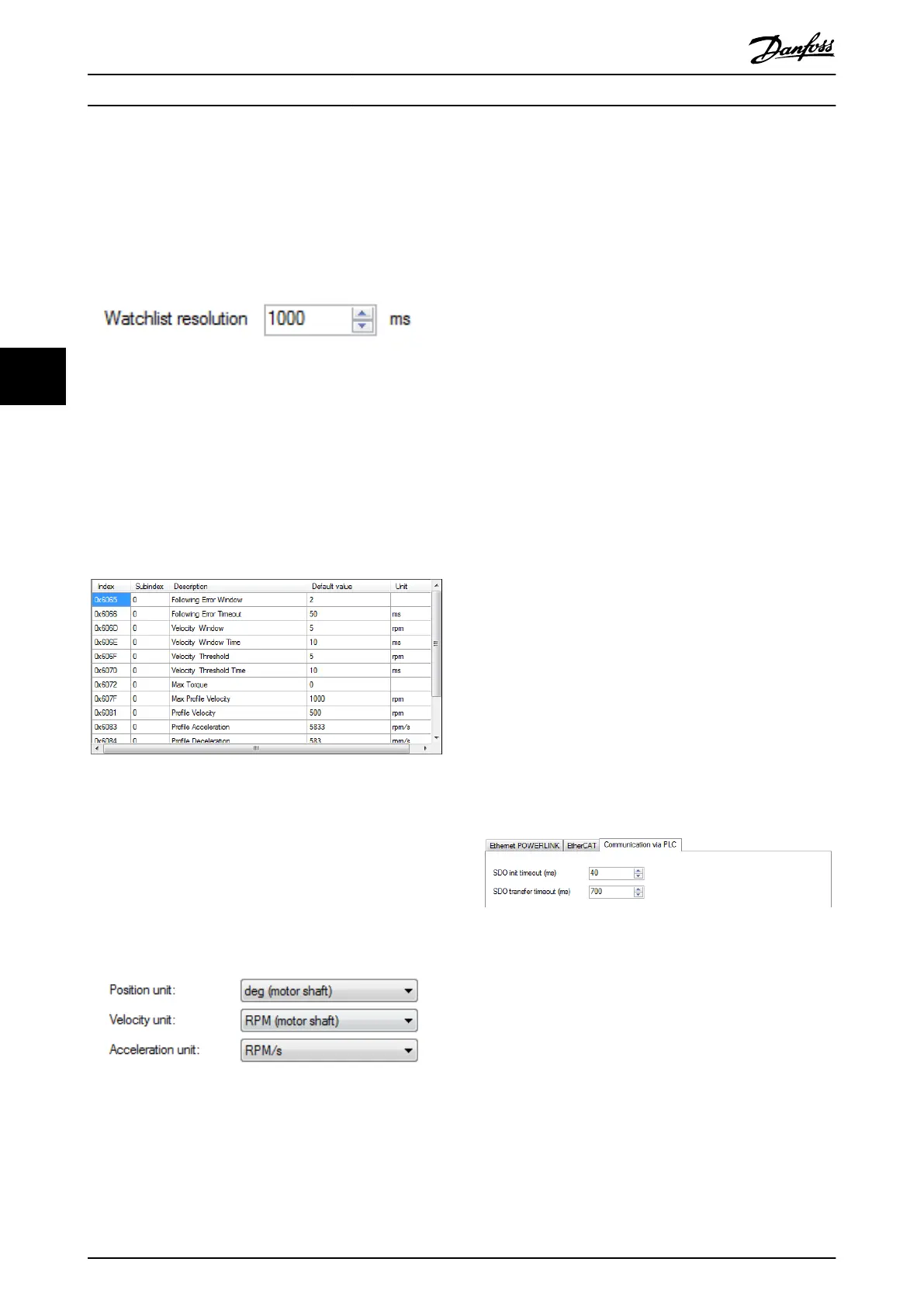

The Default values tab consists of a data grid with the

columns Index, Subindex, Description, Default value, and

Unit. It contains multiple pre-dened parameters that are

applied to devices that contain them. All default values are

used as initial RxPDO values that are transmitted to the

devices when using cyclic communication. It is not

possible to add new parameters to the list.

Illustration 5.17 Toolbox Options - Default Values Tab

The

Drive units tab contains settings for the position,

velocity, and acceleration units for drive parameters that

are scaled according to the DS402 Factor Group. These

settings are used for all drive devices but do not inuence

any parameters of the drives. They are only used for

scaling the values within the ISD Toolbox.

Illustration 5.18 Toolbox Options - Drive unit

The following units are available for scaling position,

velocity, and acceleration:

•

Position unit

- Degree

- Radian

- Revolution

•

Velocity unit

- RPM

- RPS

- Degree/sec

- Radian/sec

•

Acceleration unit

- RPM/sec

- RPS/sec

-

Degree/sec

2

-

Radian/sec

2

The

Fieldbus-specic tab contains eldbus-specic settings,

organized in the sub-tabs Ethernet POWERLINK, EtherCAT,

and Communication via PLC. Settings are not required for

Ethernet POWERLINK.

The Communication via PLC tab contains the SDO init

timeout and SDO transfer timeout values in ms. Modify

these 2 values if the connection to the PLC is slow or the

SDO channels of the devices behind the PLC are lled by

the PLC itself, and the SDO communication is therefore

slow.

The default SDO init timeout is 40 ms and the default SDO

transfer timeout is 700 ms.

Illustration 5.19 Toolbox Options -

Fieldbus-specic Tab

The Updates tab contains the functionality for searching for

new rmware packages and updating the ISD Toolbox, its

sub-tools, conguration, and online-help. This can be

triggered by clicking on the Check for Updates now button.

The check for updates procedure can also be performed

automatically when the ISD Toolbox starts. This option is

disabled per default but can be enabled by checking the

check-box Automatically check for updates when the ISD

Toolbox starts (see Illustration 5.20).

Operation with ISD Toolbox

VLT

®

Integrated Servo Drive ISD

®

510 System

120 Danfoss A/S © 01/2017 All rights reserved. MG36D102

55

Loading...

Loading...