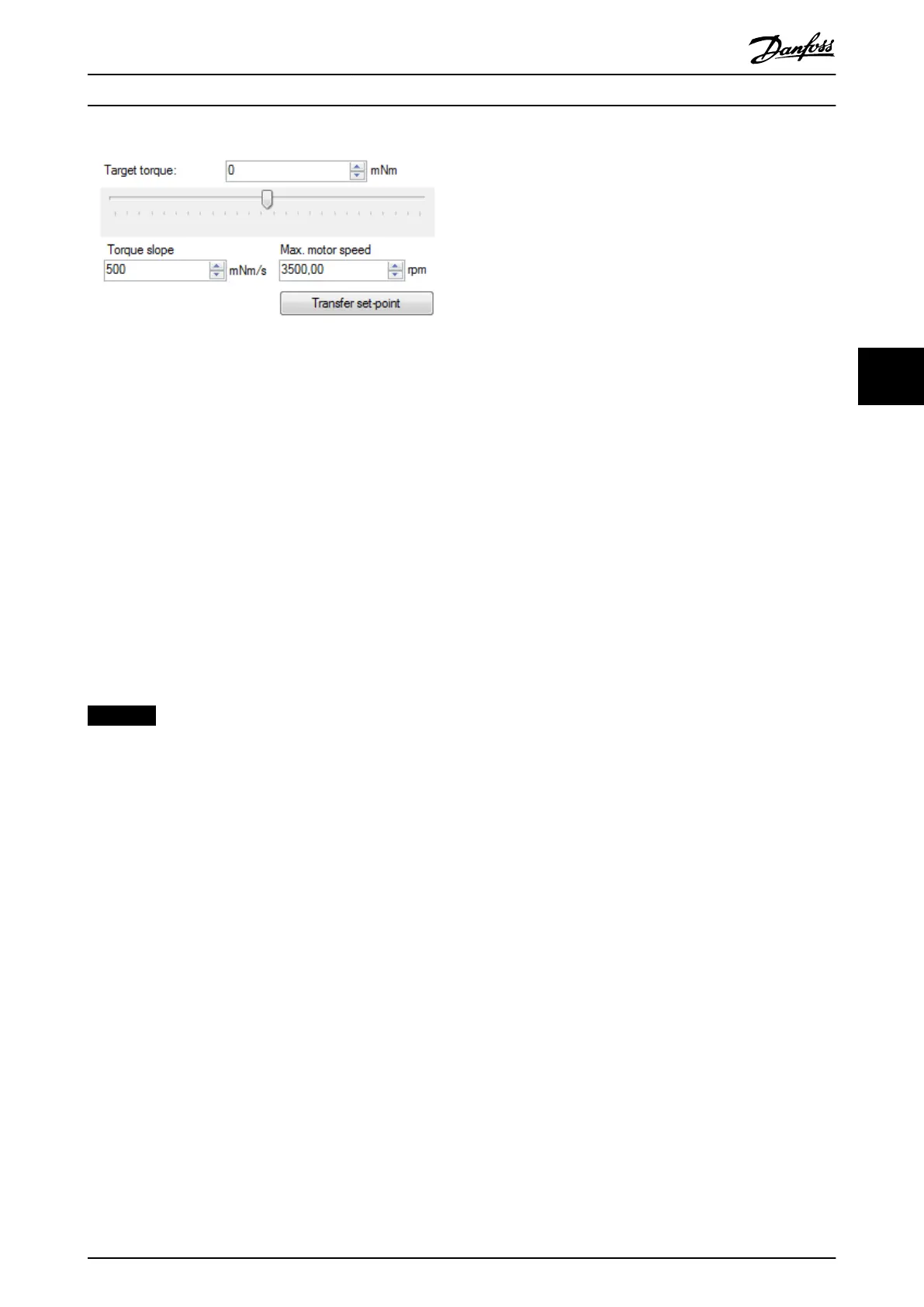

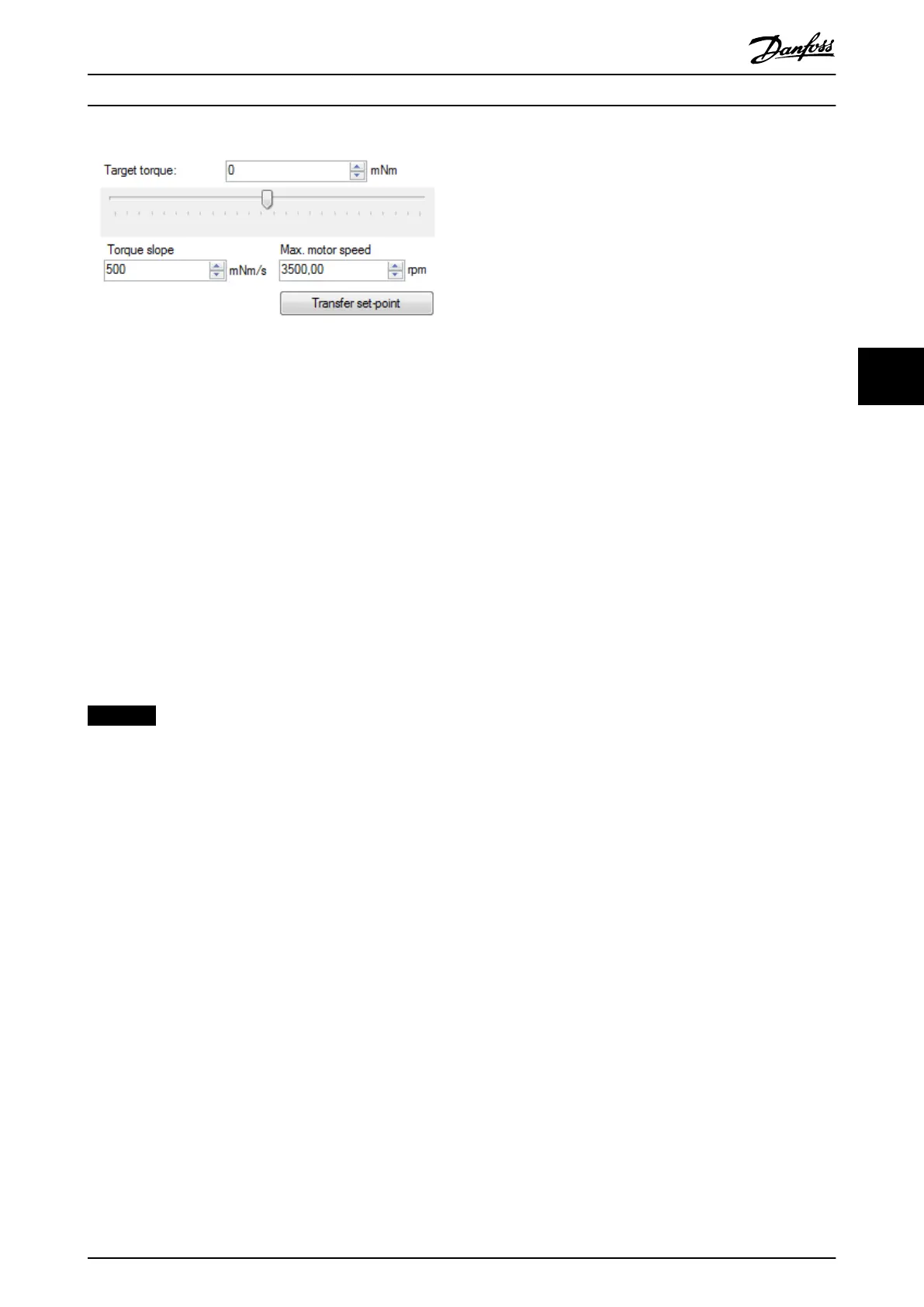

Illustration 5.44 Drive Control - Torque Prole Mode

The minimum and maximum values of both the Target

torque numeric eld and the Target torque slider are set to

match the Application torque limit parameter on the servo

drive, which is congurable in the eld for Additional

Parameters. The initial slider position is in the middle of the

slider, representing 0.

The mode of operation of the servo drive is set to Prole

Torque mode once the button Transfer set-point is clicked

or the Target torque slider is moved.

The parameters Torque slope and Max. motor speed are

needed to operate the servo drive in Torque Prole mode.

They are represented by the 2 respective numeric up/down

elds in the Torque Mode control. The Torque slope eld

shows its parameter value as mNm/s, and the Max. motor

speed eld is shown in the velocity unit set in the Options

window (see chapter 5.5.8 Options Window).

NOTICE

The Torque Prole mode control relies on cyclic

communication to send any commands to the servo

drive.

DS402 State Machine control

The DS402 State Machine control visualizes and controls the

servo drive state machine and can be used to enable or

disable the servo drive, and to reset an error. The control

can only be used in cyclic mode (direct communication), as

it sends the commands to the servo drive in the form of

process data objects (PDO).

The DS402 state machine consists of the 7 DS402 states;

every state is assigned a distinct color, has a list of

navigable successor states, and a list of automatic

transitions that can only be triggered by the drive rmware

itself. Table 5.2 in chapter 5.5.2 Device Environment Window

lists all servo drive states along with their respective colors.

The DS402 states are divided into 3 groups:

•

Power disabled

•

Power enabled

•

Fault

The DS402 state machine control that is included in the

Drive control sub-tool is shown in Illustration 5.38. The

active state is highlighted with its dened state color. and

the directly navigable successors of the active state are

accessible (enabled). The states that cannot be directly

entered from the current state are not accessible

(disabled).

The button Automatic Start up is used to transfer the servo

drive automatically to state Operation Enabled. If the state

Operation Enabled cannot be reached within 2 s, the

procedure stops automatically.

The button NMT Reset device resets the communication

state machine of the servo drive. Afterwards, automatic

traversing to the NMT state Operation takes place. As long

as the NMT state of the servo drive is not Operational, the

DS402 state machine control is disabled.

Additional Parameters area

The Additional Parameters area contains drive parameters

that are needed for using the dierent modes of operation:

•

Prole velocity (see chapter 7.5.6 Parameter 52-12:

Prole Velocity (0x6081))

•

Prole acceleration (see chapter 7.5.7 Parameter

50-11: Prole Acceleration (0x6083))

•

Prole deceleration (see chapter 7.5.8 Parameter

50-12: Prole Deceleration (0x6084))

•

Quick stop deceleration (see

chapter 7.5.9 Parameter 50-13: Quick Stop

Deceleration (0x6085))

•

Torque limit (see chapter 7.5.13 Parameters 52-15,

52-23, and 52-36: Application Torque Limit (0x2053))

The parameters are automatically read from the servo drive

when the Drive Control sub-tool is started. The units in

which the Additional Parameters elds are shown depend

on the settings in the Toolbox options window (see

chapter 5.5.8 Options Window).

The Additional Parameters can be transmitted to the servo

drive by clicking on the button Update additional

parameters.

If the Transfer with set-point checkbox is selected, the

parameters are transmitted to the servo drive every time a

mode-of-operation-specic set-point is sent to the servo

drive (for example new Target position in Prole Position

Mode or new Target velocity in Prole Velocity Mode). When

the Transfer with set-point option is selected, the Update

additional parameters button is disabled.

Halt control area

The Halt control consists of the Halt button and the halt

option text. The Halt button is used to toggle between 2

possible states: pressed, or released. When the Halt button

is pressed, the halt bit in the Controlword is set to 1;

otherwise, it is set to 0. The halt option text is obtained by

reading the halt option code (see chapter 7.20.7 Parameter

50-47: Halt Option Code (0x605D)) from the servo drive. The

halt option code cannot be changed using the Drive

Control sub-tool. Use the Parameter List sub-tool (see

Operation with ISD Toolbox Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 135

5 5

Loading...

Loading...