button to save the le. The Save error history button is

disabled until the error history is read for the rst time.

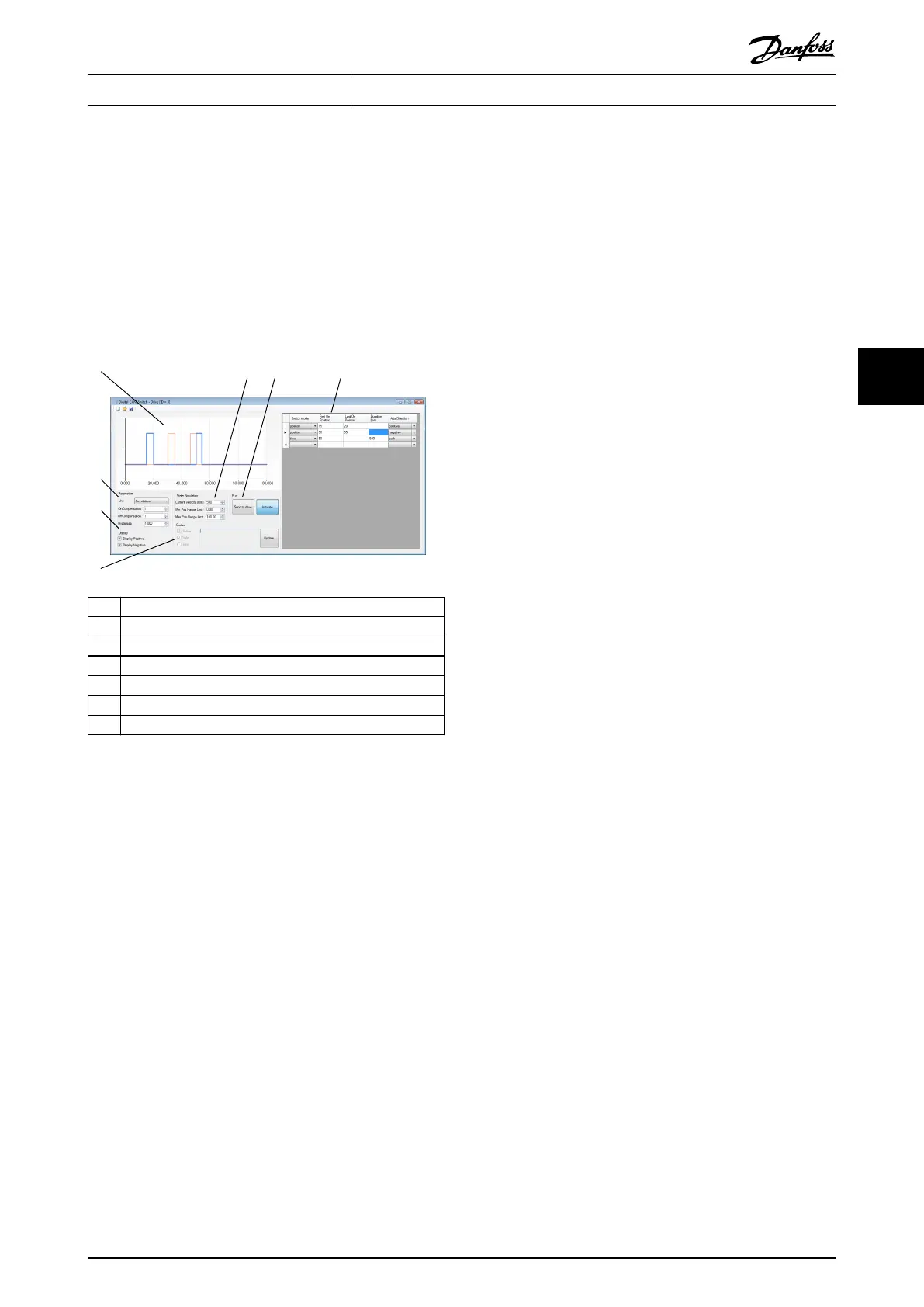

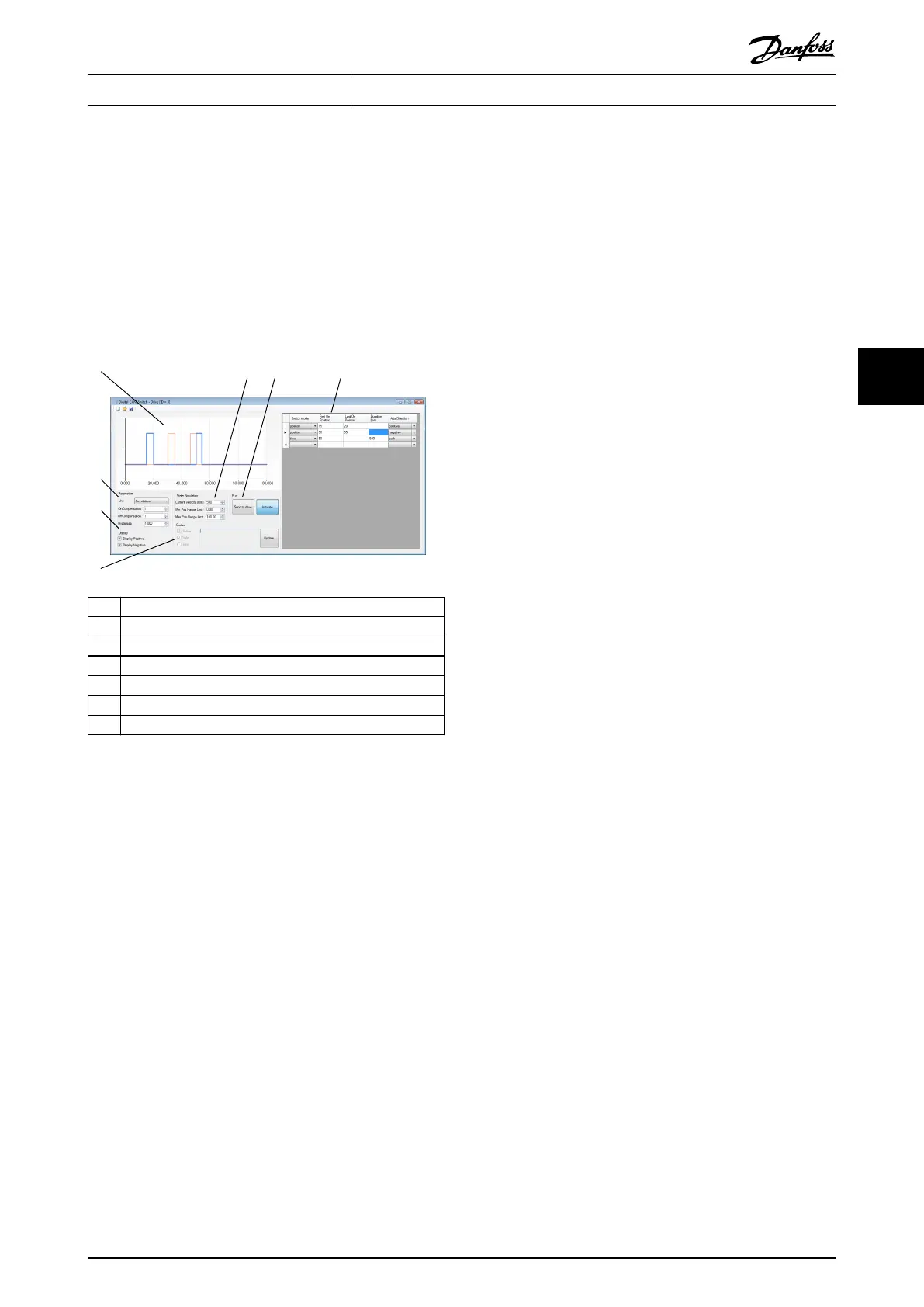

5.7.6 Digital CAM Switch (Servo Drive only)

The Digital CAM Switch sub-tool is used to create and

visualize digital CAM switch congurations, import and

export them to .dcs les, and transfer and activate them to

ISD servo drives. Illustration 5.46 gives an overview of the

Digital CAM Switch sub-tool.

1 Plot area

2 Simulation controls

3 Run controls

4 Switch denitions table

5 Status area

6 Display area

7 Parameters area

Illustration 5.46 Digital CAM Switch Sub-tool

The Parameters area contains the global switch congu-

ration. It consists of the parameters Unit (User or

Revolutions), On compensation, O compensation, and

Hysteresis. The On compensation and O compensation

values are given in milliseconds. Depending on the

selected unit, the Hysteresis value is interpreted either as

user-dened units or as revolutions. The Hysteresis eld

contains 3 decimal places that are only evaluated if the

selected unit is Revolutions. If the selected unit is User,

then only the integer part of the Hysteresis value is taken

into account.

The switch denitions table contains all switches that build

up the conguration. Every switch entry consists of the

elds Switch mode (position or time), First On Position, and

Axis Direction (positive, negative, or both).

When using switch mode position, set the Last On Position

parameter. When using the switch mode time, set the

Duration (ms) parameter. Depending on the selected unit

in the parameters area, the First On Position and Last On

Position parameters are interpreted either as user-dened

units (User) or as Revolutions.

The State Simulation and Display controls are used only for

visualization purposes and have no eect on the digital

CAM switch conguration. The horizontal plot area range is

set according to the values in the simulation elds Min Pos

Range Limit and Max Pos Range Limit. Depending on the

eld Current velocity (rpm), the length of time switches in

position units is calculated and visualized.

In the Display area, the checkboxes Display Positive and

Display Negative control if the switches in positive and

negative direction are visualized in the plot area.

The plot area graphically visualizes the digital CAM switch

denition. The horizontal plot range is dened by the

simulation parameters Min Pos Range Limit and Max Pos

Range Limit. The vertical plot axis is discrete, with values

indicating if the digital output is inactive (0) or active (1) at

any position within the plot range, given the specied

simulation velocity. Switches in positive direction are

visualized by a light blue line and switches in negative

range are visualized using a thin red line. For switches that

are dened in both directions, both a positive and a

negative visualization is made. By enabling or disabling the

visualization in positive or negative direction using the

checkboxes in the Display area, it is possible to visually

isolate and observe the resulting digital output value when

the servo drive is running in either a positive or negative

direction.

The Run controls can only be used for online servo drives.

The Send to drive button saves the digital CAM switch

conguration to a temporary le and then transmits it to

the servo drive using the le transfer protocol that is

available on the current eldbus. The Activate button sends

an activation command to the servo drive.

The Status area can only be used for online servo drives. It

shows the actual status of the digital CAM switch

functionality on the servo drive. It contains the read-only

checkboxes Active, Valid, and Error, corresponding to the

active, valid, and error bits in the digital CAM switch

parsing state object. If an error occurs, the corresponding

error text is shown in the read-only text eld in the Status

area. The status can only be manually updated using an

SDO transfer, which can be triggered by using the Update

button.

The Digital CAM Switch sub-tool can save and load digital

CAM switch congurations using the save and load

buttons in the toolbar.

Operation with ISD Toolbox Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 137

5 5

Loading...

Loading...