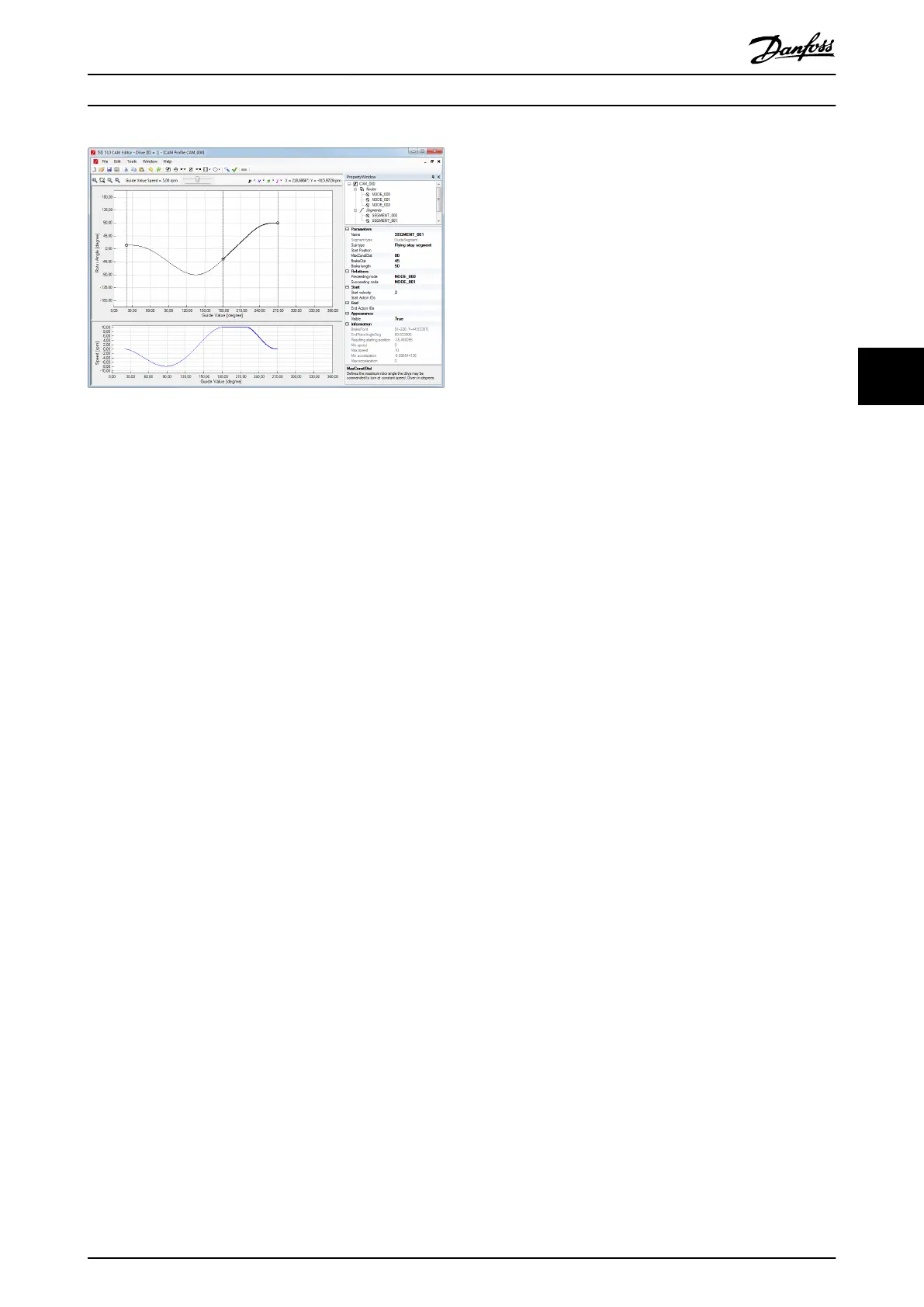

Illustration 5.74 Editing a Flying Stop Segment

Event Segment Container

The Event Segment Container does not contain specic

properties. When changing the position of the Preceding

node or Succeeding node of an Event Segment Container

(graphically or numerically), the segment is automatically

redrawn, together with all event nodes and segments it

contains.

Common event segment properties

In addition to the common segment properties, there are

properties for event segments. The properties listed here

are common for all event segments. These properties are

organized in the same groups as the base properties

common to all segments.

•

Parameters

- Duration: Species the time given in ms

from the beginning to the end of the

segment.

•

Relations

- Related container (read-only): Contains

the Event Segment Container that the

event segment belongs to.

•

End

- Exit conditions: Denes if there is 1 or

multiple exit conditions attached to this

segment. If there are no exit conditions

assigned to the segment, the duration

attribute is the only exit condition. To

dene multiple exit conditions, list all

exit IDs inside the property, separated

by a comma. If there are multiple exit

conditions, the segment is aborted as

soon as 1 of them applies (logical OR).

Time poly

The Time poly has the following properties:

•

Parameters

- Type: Denes if the segment is executed

at an absolute slave position or relative

to the previous position.

- Start position: Species the axis position

at the beginning of the segment.

Describes the position at gear in (=

motor side). If the segment type is

relative, the start position attribute only

modies the logical CAM position. In

relative segments, the property can be

left blank (unspecied). If the start

position is not specied in a relative

segment, the logical CAM position from

the previous segment is used as the

starting position.

- End position: Species the axis position

at the end of the segment. When

changing this property, the value of the

Distance property is automatically

recalculated.

- Distance: Species the distance between

the start and end axis positions

(meaning the angle to turn). Negative

distance values dene backward

movements. When changing this

property, the value of the End position

property is automatically recalculated.

•

Start

- Start acceleration: Species the

acceleration of the axis at the beginning

of the segment. Parameterized jumps

may occur in the acceleration when 2

succeeding segments have dierent End

acceleration and Start acceleration values.

- Start velocity: Species the velocity of

the axis at the beginning of the

segment. The velocities of all segments

that are connected by the same node

should be the same to ensure smooth

movement. Incorrect parameterization

results in a jump in velocity.

•

End

- End acceleration: Species the

acceleration at the end of the segment.

For more information, see Start

acceleration.

- End velocity: Species the velocity at

the end of the segment. For more

information, see Start velocity.

•

Information (all read-only)

Operation with ISD Toolbox Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 153

5 5

Loading...

Loading...