NOTICE

Put the SAB to a separate SYNC unit to avoid

interruptions in communication to the SAB if the U

AUX

supply to the servo drives is switched o due to an error.

Cycle time settings

The minimum cycle time is 400 µs. The ISD 510 devices

can run EtherCAT

®

cycle times in multiples of 400 µs or

500 µs. The devices are automatically parameterized by the

PLC on start-up, depending on the EtherCAT

®

conguration

of the physical interface. To access the system base time,

select

[SYSTEM-Conguration → Real-Time Settings] in the

TwinCAT

®

System Manager. Multiples of this base time can

then be used as EtherCAT

®

cycle times.

NOTICE

Set the task cycle time of the PLC program to be the

same as the EtherCAT

®

cycle time. Otherwise data can

get lost and performance is reduced.

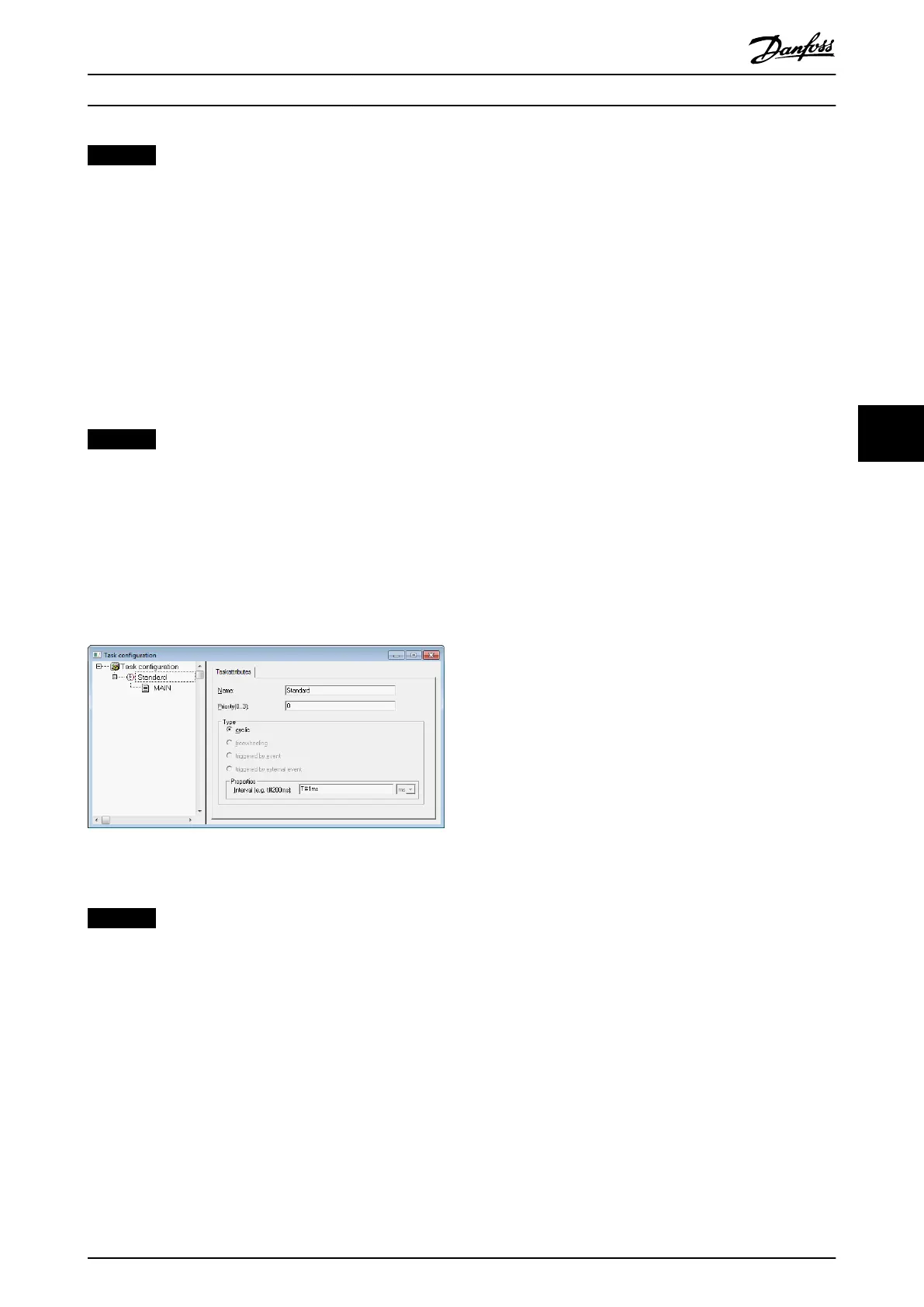

Set the PLC cycle time in TwinCAT

®

PLC Control:

1. Double-click Task conguration in the Resources

tab.

2. Ensure that the PLC cycle time is the same as the

EtherCAT

®

cycle time.

Illustration 6.9 Task Conguration to Parameterize PLC Cycle

Time

NOTICE

After changing the task cycle time in TwinCAT

®

PLC

Control, carry out a ReScan of the PLC conguration

inside the TwinCAT

®

System Manager to update the

settings. Afterwards, activate the conguration in the

PLC.

6.3.1.3

Conguration as a TwinCAT

®

NC

Axis

The servo drives can be used with the built-in NC

functionality of TwinCAT

®

. Everything related to the SAB

must be done as described in chapter 6.3.1.2 Creating a

TwinCAT

®

Project.

1. In addition to the Danfoss_VLT_ISD_510.lib le,

include the TcMC2.lib le (the

Danfoss_VLT_ISD_510.lib le is still needed for the

SAB to be operated).

2. Create 1 instance of AXIS_REF (instead of

AXIS_REF_ISD51x) for each servo drive that is used

as an NC axis.

3.

Append the PLC project into the TwinCAT

®

System

Manager, import the devices, and add them to

TwinCAT

®

as described in chapter 6.3.1.2 Creating

a TwinCAT

®

Project, however in the last step,

answer the question if the servo drive is used as

an NC axis with Yes. Then an NC task is created

automatically.

In the TwinCAT

®

System Manager, select a dierent I/O

Conguration for the servo drives used as NC axes.

1. Depending on the mode of operation to be used,

select either the slot CSP PDO or CSV PDO. Per

default, CSV PDO is mapped and pre-selected.

Map the following variables if the servo drive is

required to work with CSP PDO:

1a In the Settings Tab of the NC Axis, select

[NC-Conguration → NC-Task 1 SAF →

Axes → Axis 1]. Click on the Link To (all

Types)… button and select the desired

servo drive.

2. In the same tab, select the preferred Unit.

3. Depending on the selected Unit, adjust the

Scaling Factor for the axis encoder via menu [NC-

Conguration → NC-Task 1 SAF → Axes → Axis 1 →

Axis 1_Enc] in the Parameter tab.

Example: When the unit Degrees is selected, the

scaling factor is 360°/2

20

= 0.00034332275390625.

4. Set the Reference Velocity in the Parameter tab via

menu [NC-Conguration → NC-Task 1 SAF → Axes

→ Axis 1 → Axis 1_Enc.

5. Set the Output Scaling Factor (Velocity) to 125.

6. Test the functionality and the

conguration in the

Online tab of the axis.

6.3.1.4 Connecting to the PLC

Information on how to connect to the PLC can be found in

detail in the Beckho Information System

(infosys.beckho.com). Open the information system and go

to [TwinCAT 2 → TwinCAT System Manager → Operation →

Controls → Choose Target System].

Programming Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 167

6

6

Loading...

Loading...