When switching from a torque or velocity controlled mode to Prole position mode, the last target position is set to the

position actual value. This is relevant when starting a relative movement from the last target position after switching to this

mode, because no last target position from the previous mode is available. If the previous mode ended with a velocity

unequal to 0, the last target position is the position actual value at the time of the mode switch.

If the trajectory is completed (target position is reached) and the end velocity (see chapter 7.10.2 Parameter 52-16: End

Velocity (0x6082)) is unequal to 0, the servo drive continues rotating at the specied end velocity until a further trajectory is

set.

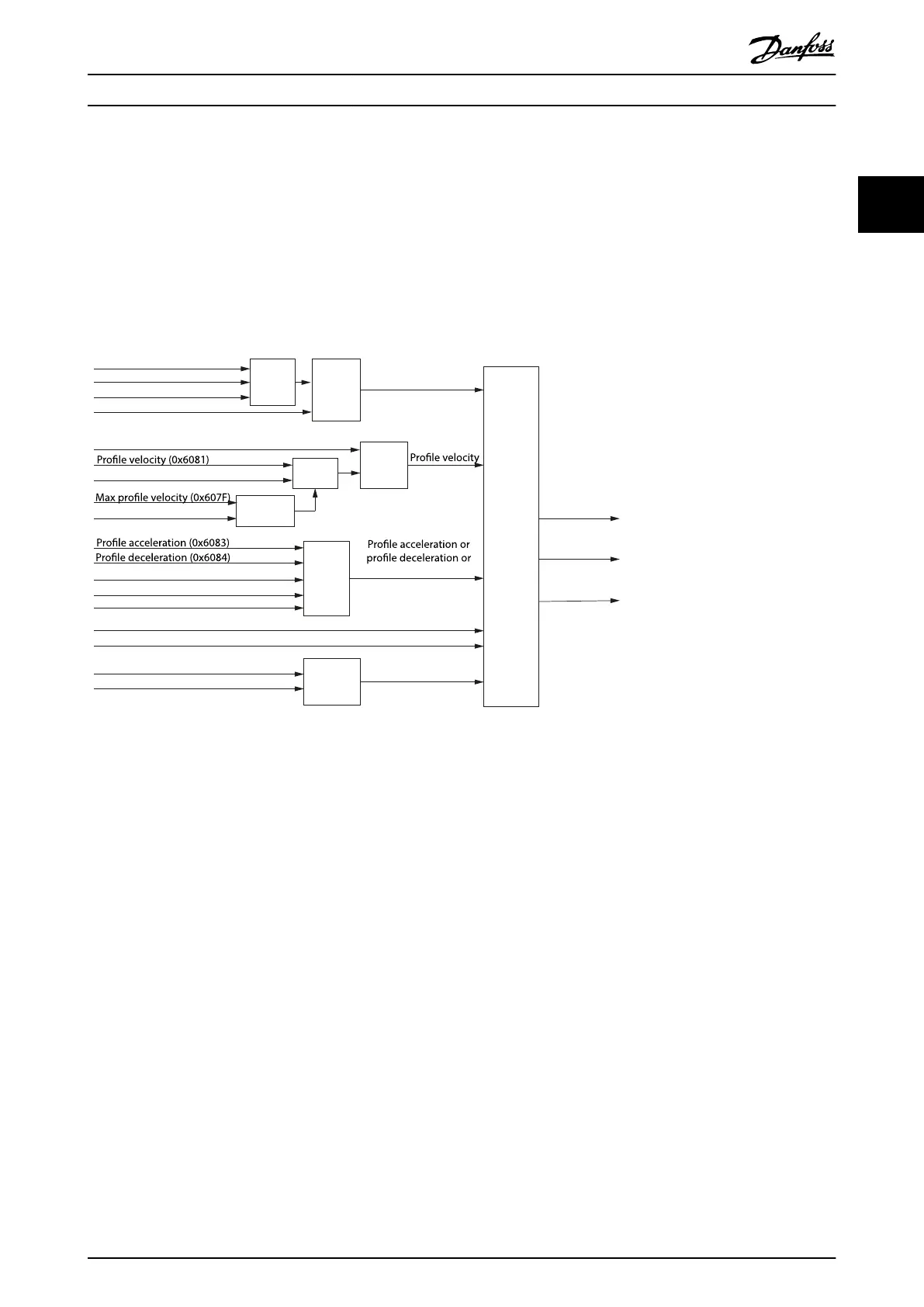

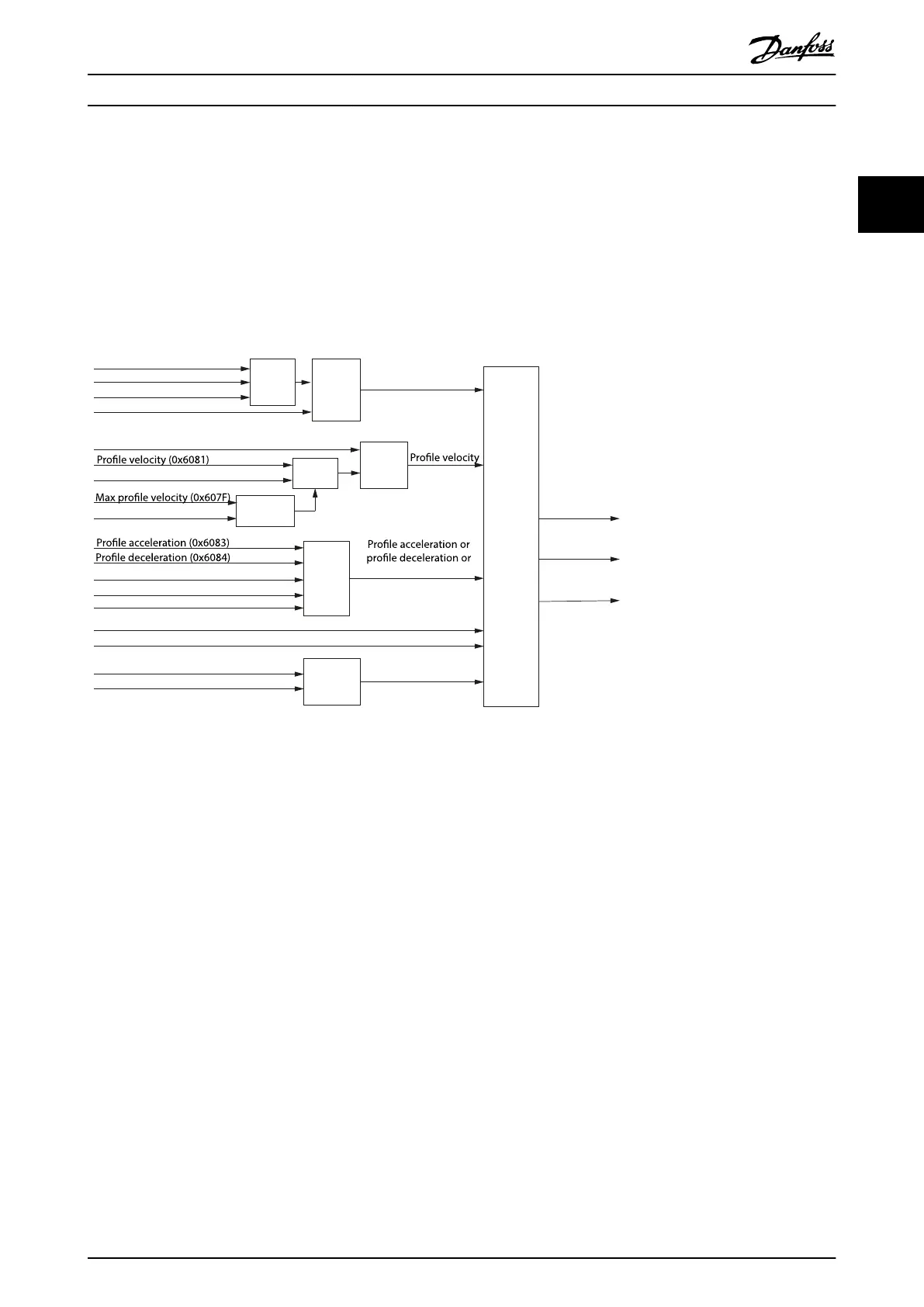

Tragectory

generator

Minimum

comparator

Minimum

comparator

Limit

function

Limit

function

Limit

function

Multiplier

Multiplier

Target position (0x607A)

Position range limit (0x607B)

Software position limit (0x607D)

Drive mirror mode (0x2016, 02)

Drive mirror mode (0x2016, 02)

End velocity (0x6082)

Max motor speed (0x6080)

Quick-stop deceleration (0x6085)

Max acceleration (0x60C5)

Quick-stop option code (0x605A)

Positioning option code (0x60F2)

Max torque (0x6072)

Application torque limit (0x2053)

Torque limit

Position demand

internal value

(0x60FC)

Feed forward

velocity

Feed forward

torque

Max deceleration (0x60C6)

quick-stop deceleration

Target position

Velocity limit

or End velocity

Illustration 2.13 Prole Position Mode Control Function

Target position activation

The activation of a setpoint is controlled by the timing of:

•

The new setpoint bit and the change set immediately bit in the Controlword.

•

The setpoint acknowledge bit in the Statusword.

If the Change set immediately bit of the Controlword is set to 1, a potentially ongoing motion is interrupted and the new

setpoint is used immediately. If the Change set immediately bit of the Controlword is set to 0, the ongoing positioning

command is nished rst and the new setpoint is executed afterwards.

After a setpoint is applied to the servo drive, the control device signals that the setpoint is valid by a rising edge of the new

setpoint bit in the Controlword. The servo drive sets the setpoint acknowledge bit in the Statusword to 1. Afterwards, the

servo drive with the setpoint acknowledge bit set to 0 signals its ability to accept new setpoints. An example is shown in

Illustration 2.14.

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 27

2 2

Loading...

Loading...