MoveDistanceSegment:

MoveDistanceSegments are used for movements with no

predened rotation angle. The desired rotor angle is given

to the axis during run-time. It must be given before the

beginning of the segment. It must be given in every

machine cycle (see Table 2.53 in chapter 2.4.5.6 Commands

During Operation).

This segment is mostly used together with an external

camera for object alignment. The start and end velocity,

and the start and end acceleration can be parameterized.

The parameter that is sent during run-time must be given

in revolutions of rotor angle. The rotor angle must be sent

at least 5 ms before the segment begins.

If no parameter is sent for this segment, the axis reports an

error (see chapter 2.4.5.7 Notications from the Servo Drive)

and assumes a distance of 0. An error message is sent

when passing the precNode of this segment. A new

parameter message, meant for the next cycle, can be sent

to the servo drive when the succNode of this segment has

been passed.

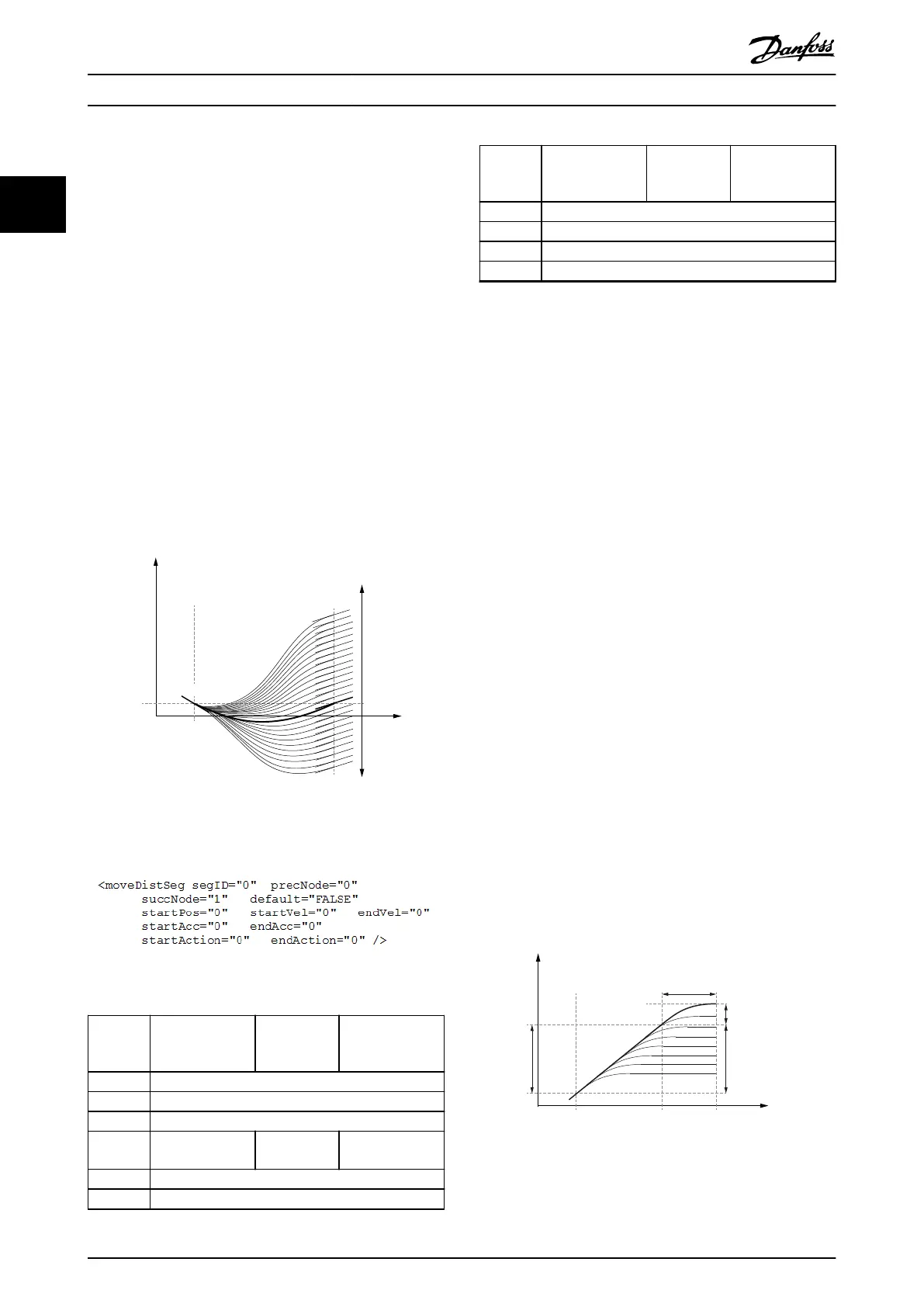

130BF293.10

Guide

value

Rotor angle

of axis

startPos

endVel

startVel

succNode

precNode

Distance is variable;

needs to be sent at

run-time in every

machine cycle

Illustration 2.86 MoveDistanceSegment

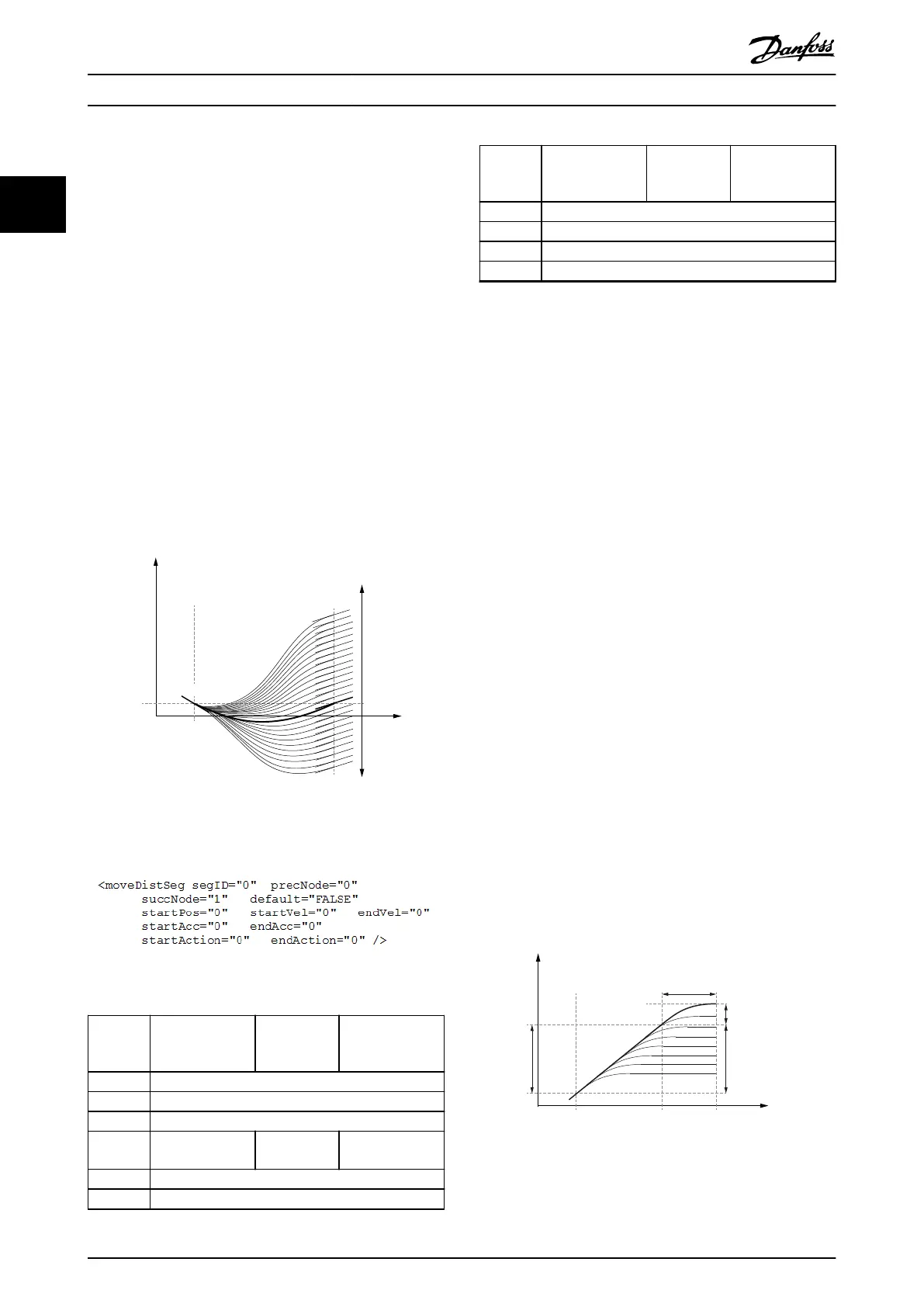

Illustration 2.87 Start/Endpoint Representation

Attribute

Mandatory/

optional

(+default value)

Value range/

allowed

values

Description

segID Same as in Table 2.17.

precNode Same as in Table 2.17.

succNode Same as in Table 2.17.

startPos O Float See Table 2.18 for

type= relative.

startVel Same as in Table 2.18.

endVel Same as in Table 2.18.

Attribute

Mandatory/

optional

(+default value)

Value range/

allowed

values

Description

startAcc Same as in Table 2.18.

endAcc Same as in Table 2.18.

startAction Same as in Table 2.17.

endAction Same as in Table 2.17.

Table 2.20 Attributes for MoveDistanceSegment in

Start/Endpoint Representation

Coecient representation: This representation is not

available.

FlyingStopSegment:

The FlyingStopSegment is used to stop the servo drive out

of a synchronous movement at a position, which can be

determined at run-time. This angle is usually determined

by a camera system. The motion consists of 2 parts, a

constant rotation, which length is dened by the sent

parameter, and a deceleration polynomial for stopping the

servo drive (a polynomial of 3

rd

degree is used). The angle

must be passed before the segment has started. The

parameter can be in a range from 0° to maxConstantDist.

The value is given as an absolute value. The direction is

determined by the direction of the velocity.

The rotor angle must be sent during run-time but before

the beginning of this segment. When the constant part has

been processed for the parameter, which was given, the

stopping part of the segment starts. This braking

polynomial is always the same, independent of the

remaining distance to the end of the segment.

The parameter that is sent during run-time must be given

in revolutions of rotor angle. The rotor angle must be sent

at least 5 ms before the segment begins. If no parameter is

sent for this segment, the axis reports an error (see section

Notications from the servo drive in this sub-chapter) and

assumes a distance of maxConstDist. The error message is

sent when passing the precNode of this segment. A new

parameter message, meant for the next cycle can be sent

to the servo drive when the succNode of this segment was

passed.

Guide

value

Rotor angle

of axis

startPos

succNodeprecNode

maxConstDist

startVel

brakeLength

brakeDist

Distance is variable;

needs to be sent at

run-time in every

machine cycle

130BF294.10

Illustration 2.88 FlyingStopSegment

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

58 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...