For basic CAMs, use the slave relative option. A jump

occurs if the CAM starts with an absolute movement and

the servo drive is at a dierent position. No blending

occurs.

Segment parameter during run-time

This command sends a parameter to a specic segment.

The parameter inuences the behavior of the segment

during run-time. Segment types that expect an angle

parameter at every guide value cycle (master cycle) are

Move Distance segments and Flying Stop segments (see

chapter 5.7.7.7 Editing Advanced CAM Proles).

The specic segment is addressed using its ID. The

parameter is a oating point value given in rotor shaft

revolutions.

Set follow segment

This command instructs the servo drive to change the

used succeeding segment of a node. It is only possible to

select a segment ID that already has this node ID dened

as preceding node. This change is preserved over the

guide value cycles. Therefore, no automatic switching back

takes place.

Node signaling status

This command enables/disables the signaling of a node/

data point. That means that the servo drive can send a

notication when passing a node/data point. If there are

too many notications coming from the axis, others could

be delayed. Basic CAMs do not signal the passing of a data

point per default.

Go to setpoint

This command issues a movement to the setpoint of the

CAM while the Guide Value velocity is 0. This is used, for

example, when starting up a CAM with slave absolute and

the servo drive is at another position. The required

movement is then calculated by the servo drive automat-

ically, based on the direction option code (see Table 2.55)

over the specied time. This movement takes place using a

polynomial of 5

th

degree. The Guide Value velocity must

stay at 0 until this movement is nished.

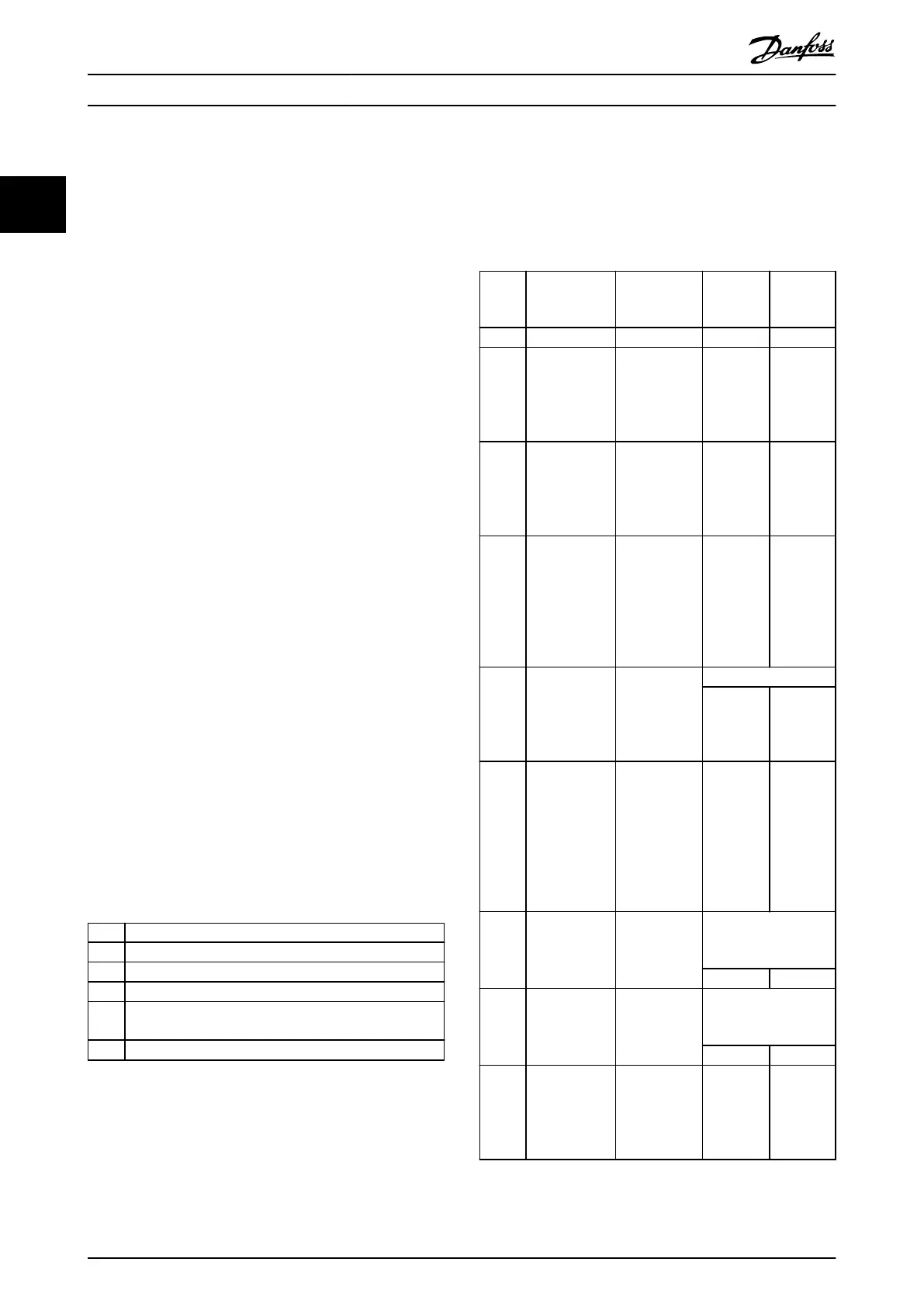

Value Denition

0 Normal movement similar to linear axis.

+1 Movement only in negative direction.

+2 Movement only in positive direction.

+3 Movement the shortest way. Assuming a rotary axis. Cam

slave scaling is considered (regarding a possible gear).

+4 Movement in last direction.

Table 2.55 Direction Option Code

2.4.5.7 Notications from the Servo Drive

The servo drive sends out information about the currently

ongoing CAM execution or as a reaction on a command.

Bit 16 (MSB) of the status code is a toggle bit. As

synchronous eldbuses are supported, it is not possible to

distinguish between a new and a resent notication.

Therefore, the edge of the toggle bit must be monitored.

The CAM status information is represented in 4 16-bit

objects (see chapter 7.14.2 Parameter: CAM Status (0x3801)).

One of them is the status code, whereas the rest contains

additional information (see Table 2.56).

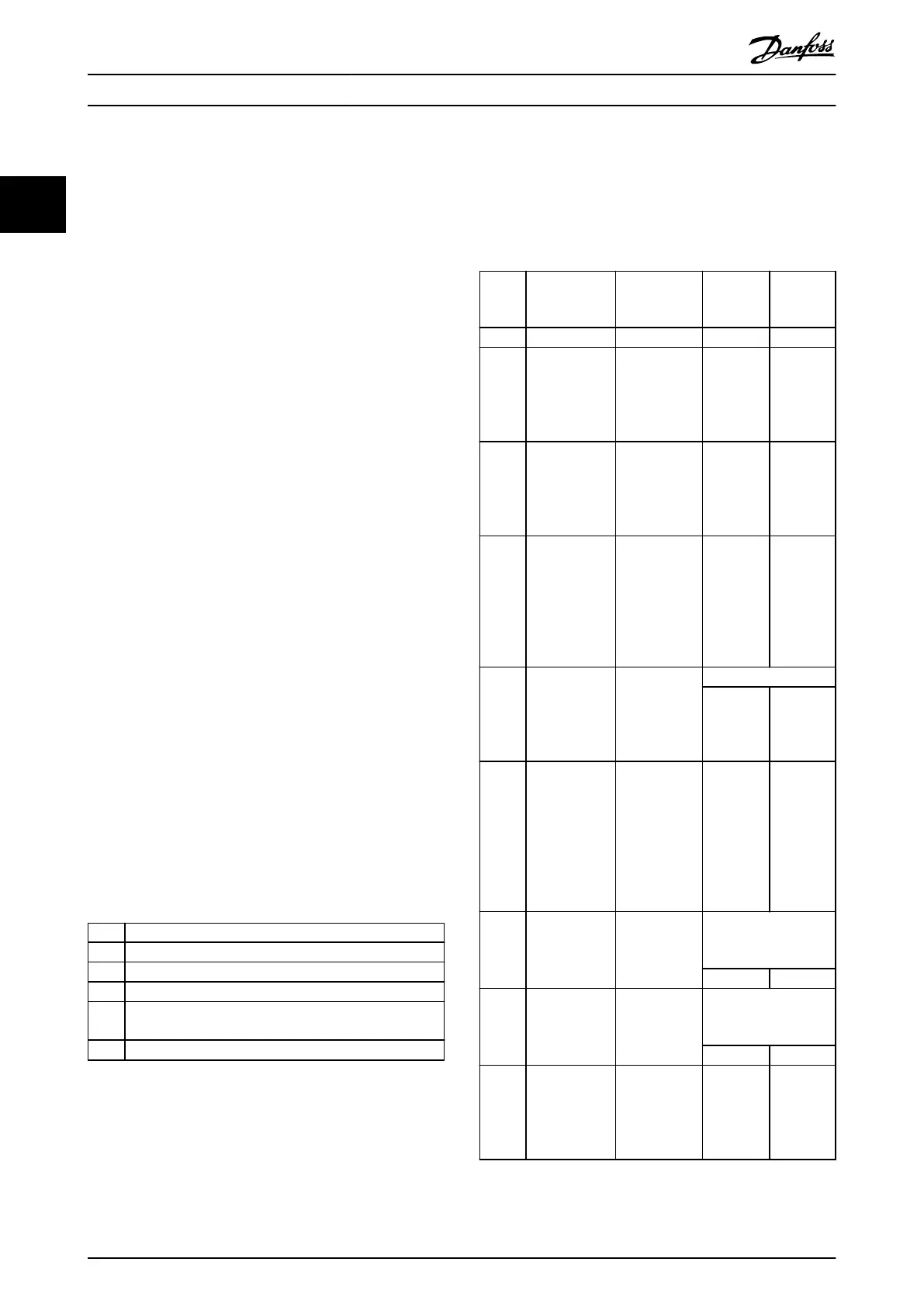

Status

code

Meaning Status

parameter

1

Status

parameter

2

Status

parameter

3

0x0000 Reserved Reserved Reserved Reserved

0x0002 Result of

dynamic

alignment

SegmentID of

alignment

segment

(pattern or

mark)

1: Success

0: Failure

Reserved

0x0004 Following error

(also signaled

in the

Statusword)

SegmentID of

the segment

in which the

following error

occurred

Reserved Reserved

0x0005 Node/data

point passed

nodeID/data

point that was

passed

SegmentID

of current

segment/n

ot

available

for basic

CAM

Reserved

0x0006 Bad parameter

sent to a

segment or

segment does

not exist

Sent

SegmentID

Sent parameter [oat]

Low byte High byte

0x0007 Bad parameter

sent: Error

when setting

following

segment of a

node (node or

segment not

valid)

Sent

SegmentID

Sent

nodeID

Reserved

0x0009 Correction

angle

indication

ID of MoveDis-

tanceSegment

Logical rotor angle

[oat; given in

revolutions]

Low byte High byte

0x000A Flying stop

angle

indication

ID of Flying-

StopSegment

Logical rotor angle

[oat; given in

revolutions]

Low byte High byte

0x000B Forced Time-

exit;

EventSegment-

Container too

short

ID of EventSeg-

mentContainer

Reserved Reserved

Table 2.56 CAM Control Data Information

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

76 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...