The PLC library provides the information in function block

chapter 6.5.6.9 DD_ReadCamInfo_ISD51x.

2.4.6 Gear Mode

In Gear mode, the servo drive executes a synchronized

movement based on a master axis by using a gear ratio

between the master and the slave position. The guide

value can be provided by an external encoder, virtual axis,

or the position of another axis. This functionality can be

commanded using function block MC_GearIn_ISD51x (see

chapter 6.5.5.9 MC_GearIn_ISD51x) and

MC_GearInPos_ISD51x (see

chapter 6.5.5.10 MC_GearInPos_ISD51x).

The slave axis calculates its position out of the master

position value (see chapter 7.8.1 Parameter: Position Guide

Value (0x2060)). The slave axis sets its target position

corresponding to the congured gear ratio (see

chapter 7.15.1 Parameter: Gear Ratio (0x3900)). The principle

of the Gear mode is shown in Illustration 2.114.

Master axis

Master position

Slave

position

Slave drive

Slave axis

Gear acceleration

Gear deceleration

Gear ratio numerator

Gear denominator

130BF573.10

Illustration 2.114 Gear Mode Description

The slave velocity is calculated as:

x master velocitySlave velocity =

gear ratio numerator

gear ratio denominrator

To start a geared movement, the acceleration (see

chapter 7.5.7 Parameter 50-11: Prole Acceleration (0x6083))

and deceleration (see chapter 7.5.8 Parameter 50-12: Prole

Deceleration (0x6084)) can also be congured. These

parameters are also used to link up the gear. The slave

ramps up or down to the ratio of the master velocity

according to the given acceleration or deceleration value

and locks in when this velocity is reached.

There are 2 synchronization methods:

•

The relative synchronization between the master

and the slave is important (Gear In functionality).

For the Gear In functionality, the synchronization

phase is velocity controlled, so any lost distance

during synchronization is not caught up.

•

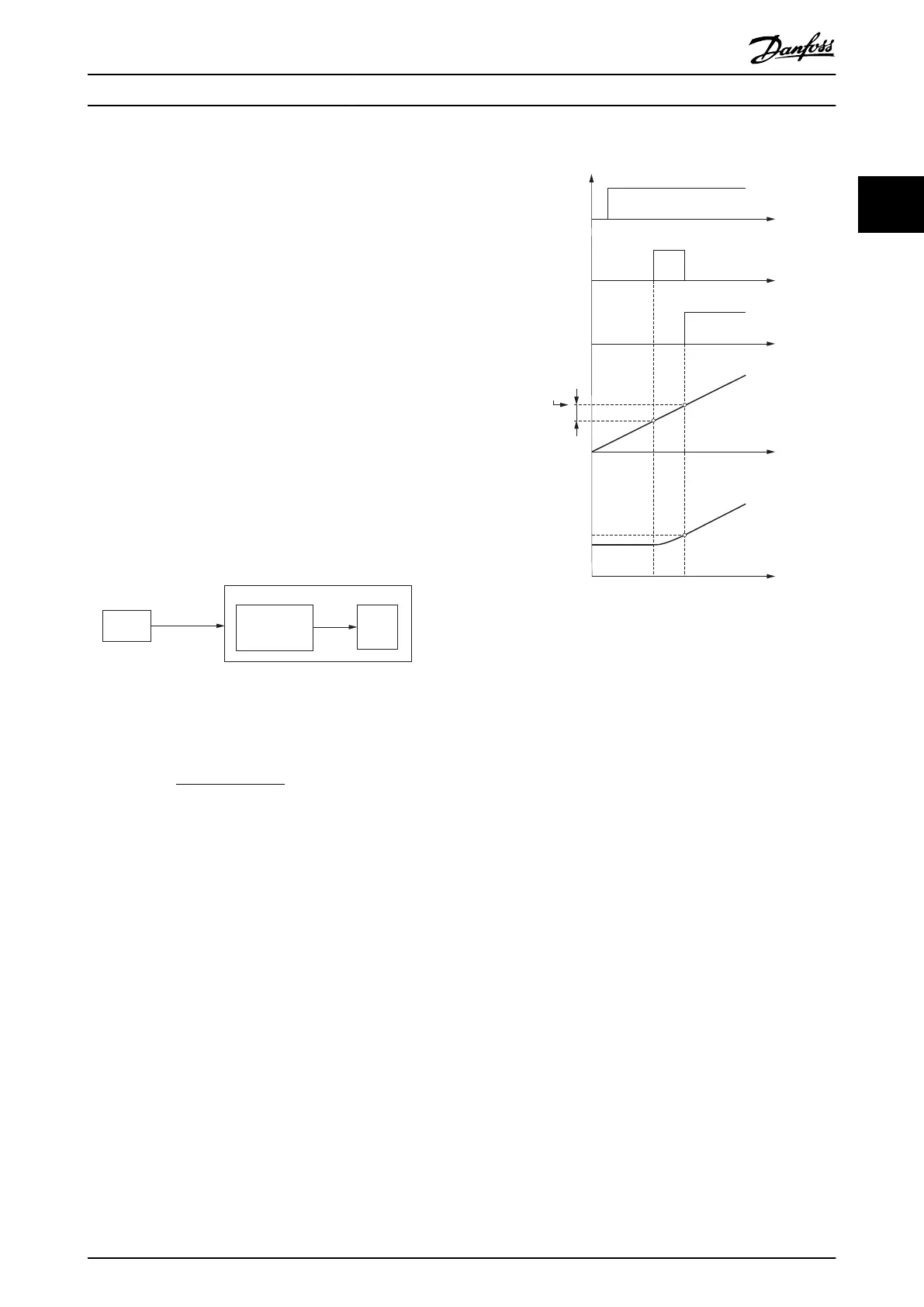

The absolute relation between master and slave is

important (Gear In Pos functionality), as shown in

Illustration 2.115.

t

t

t

t

t

TRUE

FALSE

Master sync position

Master start distance

Slave sync position

Execute

Start sync

Insync

130BF574.10

TRUE

TRUE

FALSE

FALSE

FALSE

Illustration 2.115 Timing Diagram for Gear In Position

Procedure

A polynomial of maximum 5

th

degree is used for the

synchronization phase.

The mode is activated by writing –7 to object 0x6060.

For the Controlword (see chapter 7.2.1 Parameter 16-00

Controlword (0x6040)) and the Statusword (see

chapter 7.3.1 Parameter 16-03 Statusword (0x6041)), the bits

that usually hold the operating mode-specic bits are

dened here.

Depending on the value of the Guide value option code

object (see chapter 7.8.3 Parameter: Guide Value Option

Code (0x2061)), the guide value (backward or forward

movement) must be handled. The parameters

specic to

this mode are listed in chapter 7.15 Gear Mode Objects.

2.4.7 ISD Inertia Measurement Mode

This mode measures the inertia of an axis. It is used to

measure the inertia of the servo drive and the external

load, and can be used to optimize the control loop

settings. The friction eects are eliminated automatically.

This functionality can be commanded using function block

DD_GetInertia_ISD51x (see

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 77

2 2

Loading...

Loading...