4 Transport, installation and commissioning

Commissioning

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

Page

4 - 33

Performing a manual purge

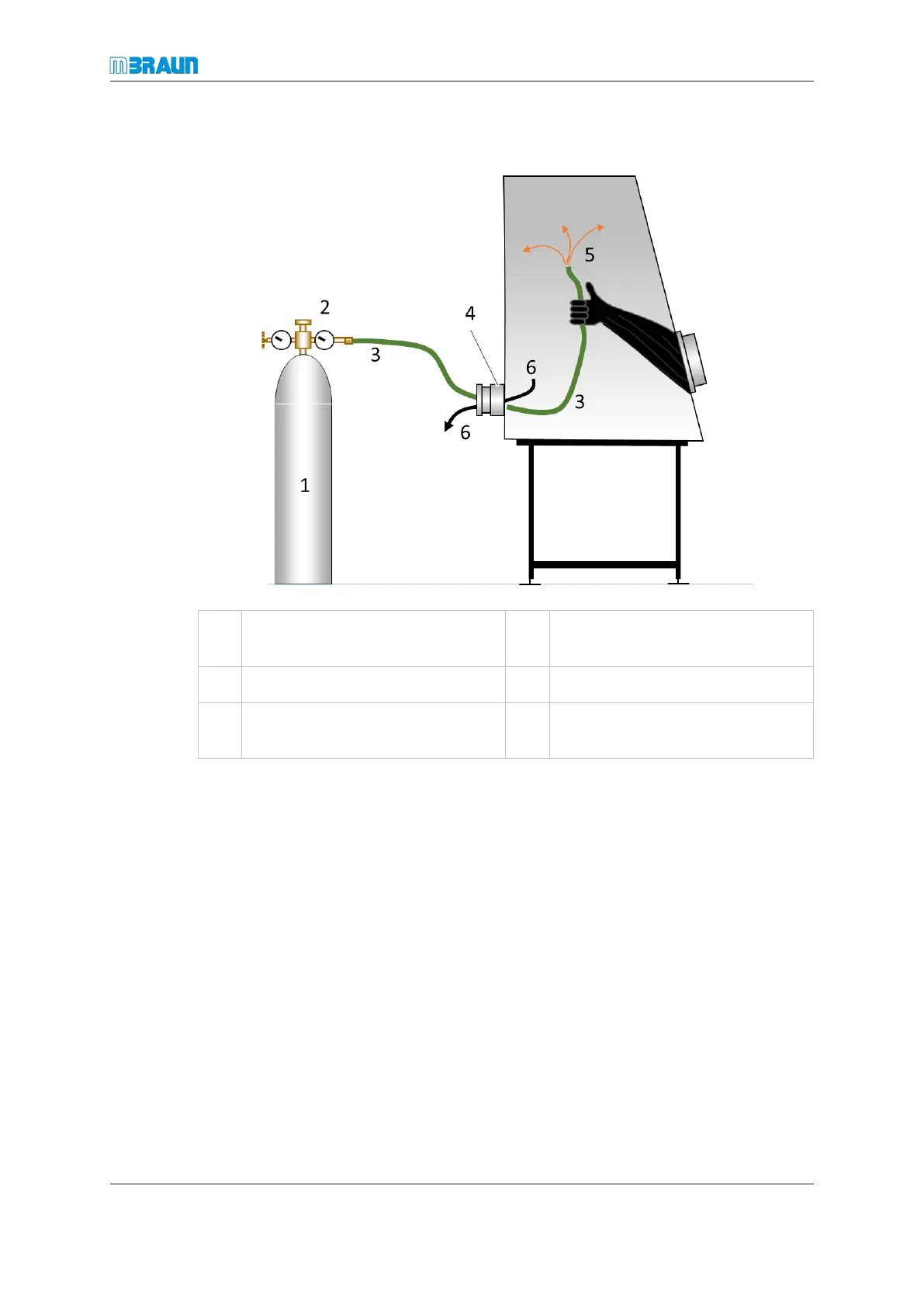

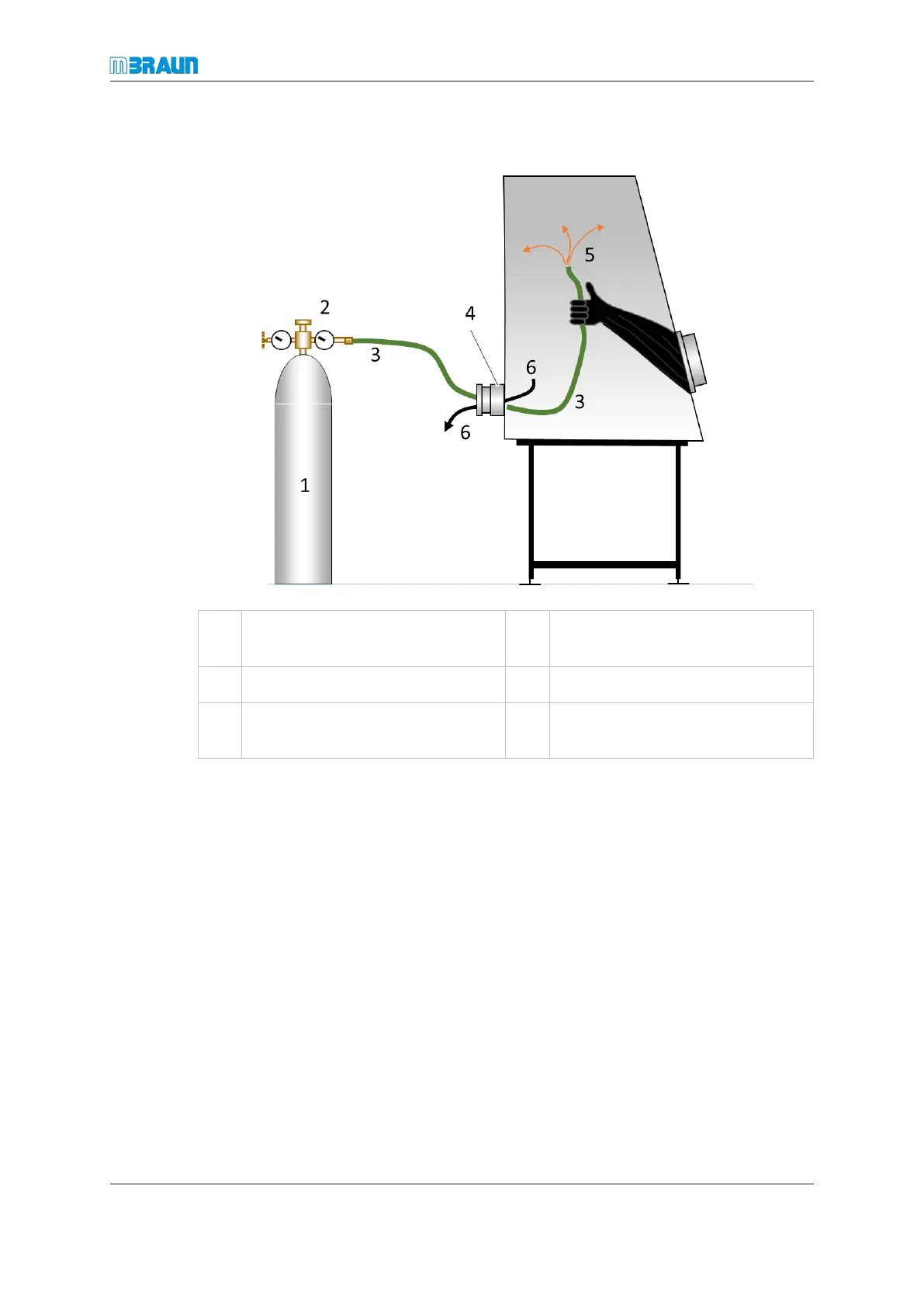

1 Purge gas source 2 Pressure reducing valve, 3.0 bar

(0.3 MPa)

3 Reinforced hose 4 Open flange

5 Inert gas exhaust into the glovebox 6 Mixed ambient air and inert gas es-

cape

► In a two-glovebox system, each glovebox must be purged separately. Both boxes

must have an open connection to the circulation pipework.

► Open freezers or equipment with areas that may be protected by covers.

► Set up purge gas source (working gas) with pressure reducing valve.

► Connect reinforced hose to purge gas source.

► Open one KF40 “blind flange” on glovebox.

► Feed one end of the reinforced hose through the open flange into the gloves.

► Set the pressure-reducing valve on the purge gas source to 3.0 bar (0.3 MPa) and

open the valve.

ð Air and purge gas escapes through the flange opening.

► Pick up the reinforced hose with a glove, and purge the glovebox interior from top to

bottom using a circular motion.

► Carefully purge corners, edges and box fittings.

The purge time should be about 45 min per 1m

3

of glovebox volume to achieve an appro-

priate gas displacement with an oxygen concentration of less than 100 ppm (V).

Loading...

Loading...