4 Transport, installation and commissioning

Installation

Page

4 - 18

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

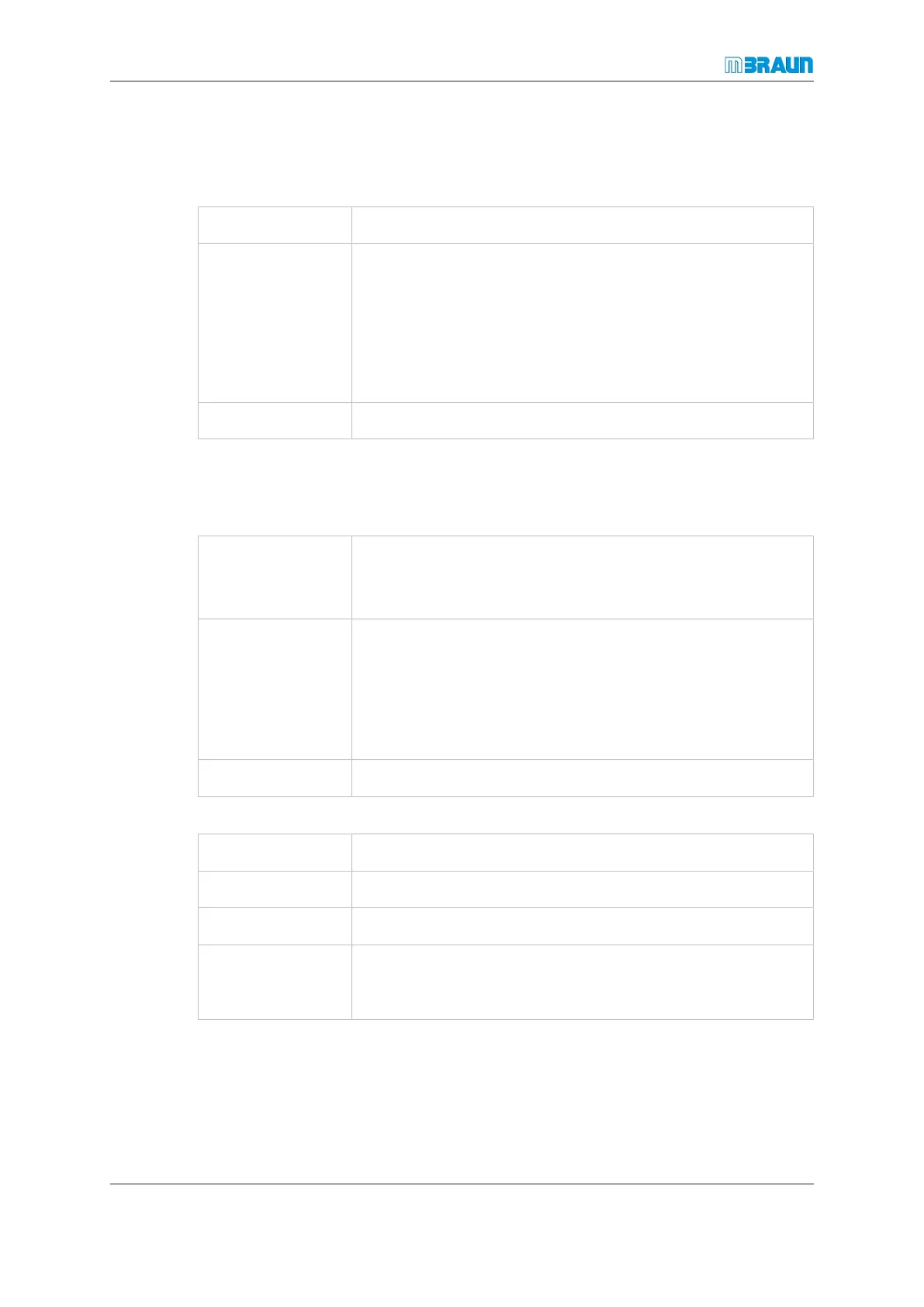

Inlet (3a)

Connection equipment provided by operating company: connecting the regeneration

pressure regulator to the regeneration gas inlet hose.

Use Feed pipe for regeneration gas

Material Length as required:

¡ Either Ø 9 mm reinforced hose, 3 mm wall thickness and ad-

apter, Ø 9 mm hose nozzle with Ø 10 mm Swagelok fitting

¡ Or Ø 10 mm copper pipe and Ø 10 mm Swagelok fitting

¡ Or Ø 10 mm stainless steel pipe and Ø 10 mm Swagelok fit-

ting

Connection type Ø 9 mm hose nozzle or Ø 10 mm Swagelok fitting

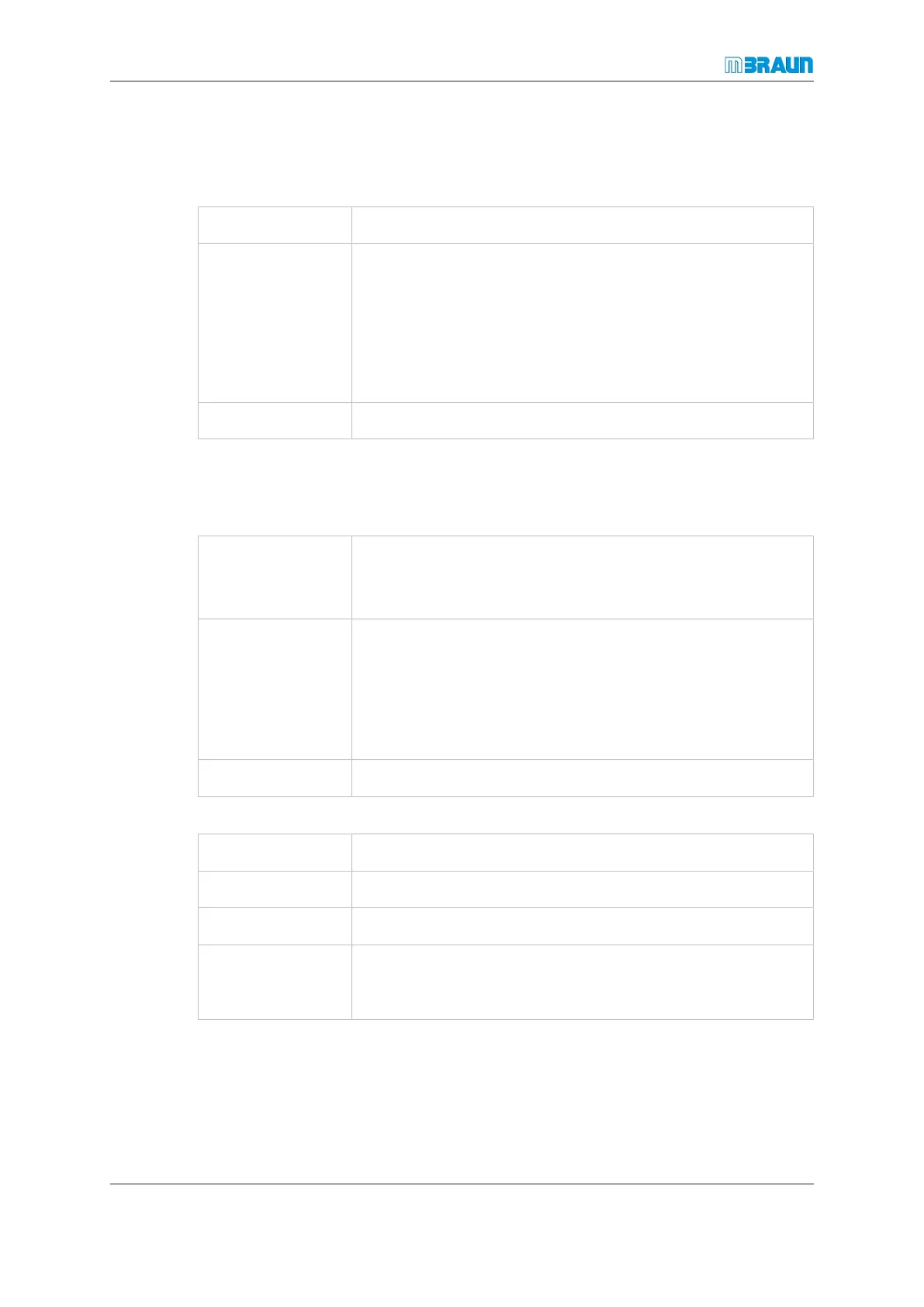

Outlet (3b)

Connection equipment provided by operating company: exhaust outlet for waste regener-

ation gas.

Use Connecting the regeneration gas outlet at the gas purifier to the

operating company’s disposal equipment (exhaust outlet).

Wet gases

Material Length as required

¡ Either Ø 9 mm reinforced hose, 3 mm wall thickness and ad-

apter

¡ Or Ø 10 mm copper pipe

¡ Or Ø 10 mm stainless steel pipe

Connection type Ø 9 mm hose nozzle or Ø 10 mm Swagelok fitting

If a regenerative solvent filter(s) is in place:

Use Same line as for regenerating gas outlet (3b)

Gas type Working gas with solvents concentrations

Quantity Approx. 3.5 m

3

per each regeneration

Solvent exhaust

system tape on op-

erators premises

Explosion-proof exhaust line required

System cooling (4a/4b)

Cooling of the system is optional and is not a requirement. For further information refer to

System cooling [}4 - 20].

Loading...

Loading...