Requirement

WARNING

Electric shock when the motor temperature sensor insulation fails

When connecting temperature sensors which are not isolated from the motor power circuit

according to safe electrical separation, arcing to the signal electronics may occur.

• Use motors whose temperature sensors have safe electrical separation.

• Use only connecting cables and connectors with safe electrical separation between the

cores of the temperature sensor and the cores of the power circuit.

• If safe electrical separation cannot be guaranteed (for linear motors or third-party motors,

for example), use a Sensor Module External (SME120 or SME125) or Terminal Module

TM120.

Only use the temperature sensor input of the Motor Module if the following conditions are

fullled:

• The connected motors are not equipped with an integrated DRIVE-CLiQ interface.

• The temperature values are not acquired via another component (Sensor Module Cabinet,

Sensor Module External, Terminal Module).

Description

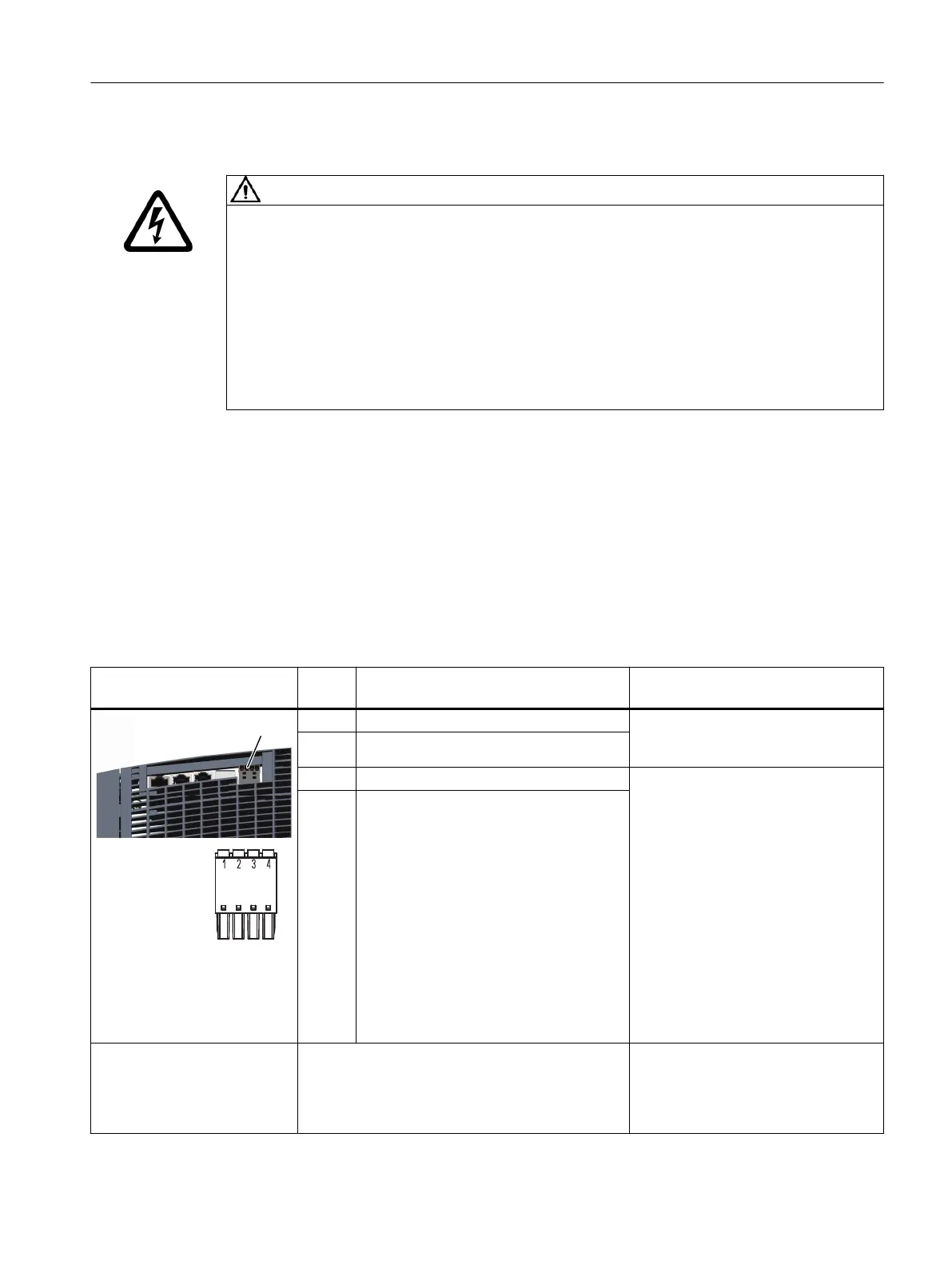

Table 8-19 X21: EP terminal/temperature sensor for Motor Modules 45 ... 200A

X21: EP terminals / tempera‐

ture sensor

Termi‐

nal

Designation Technical data

1 + Temp Temperature sensors

1)

: Pt1000 / PTC /

KTY84-130 / bimetallic switch with NC

contact

2 - Temp

3 EP + (Enable Pulses +) Voltage: -3…+30VDC

Electrical isolation: Yes

Input characteristic acc. to

IEC61131-2, type1 and type3

Input voltage (including ripple)

"1" signal: 11…30V

signal "0": -3…+5V

Input current

at 24VDC: 2.5...4mA

at < 1.5 mA: "0" signal reliably detected

Input delay

for "0" → "1": typ.25μs / max.50μs

for "1" → "0": typ.110μs+2μs/m /

max.150μs+4μs/m

4 EP M (Enable Pulses M)

Connectable cable cross-sec‐

tions

Rigid, exible

Flexible, with end sleeve without protective collar

Flexible, with end sleeve with protective collar

AWG / kcmil

0.25...1.5 mm

2

0.25...1.5mm

2 1)

0.25...0.75 mm

2

24…16

Motor Modules

8.4Motor Modules 45 A and 60 A

Booksize power units

Equipment Manual, 09/2023, A5E53307519B AA 189

Loading...

Loading...