4. Shorten the single cores to length "a" according to the table above. The stripped lengths of

the motor cables are the same for all cross-sections.

5. Remove length "b" of the insulation from the single cores according to the table above.

8.3.10.3 Prepare end sleeves

Requirement

The following requirements must be satised in order to crimp the end sleeves:

• You will need a crimping tool. We recommend the following crimping tool from Weidmüller

(www.weidmueller.com):

– Type PZ 6/5, article number 9011460000

• Use end sleeves compliant with DIN46228.

Procedure

Proceed as follows to attach end sleeves to the cable of the motor and the holding brake:

1. Match the cross-sections of the end sleeves and the motor connection cable according to the

following table.

2. Crimp the end sleeves.

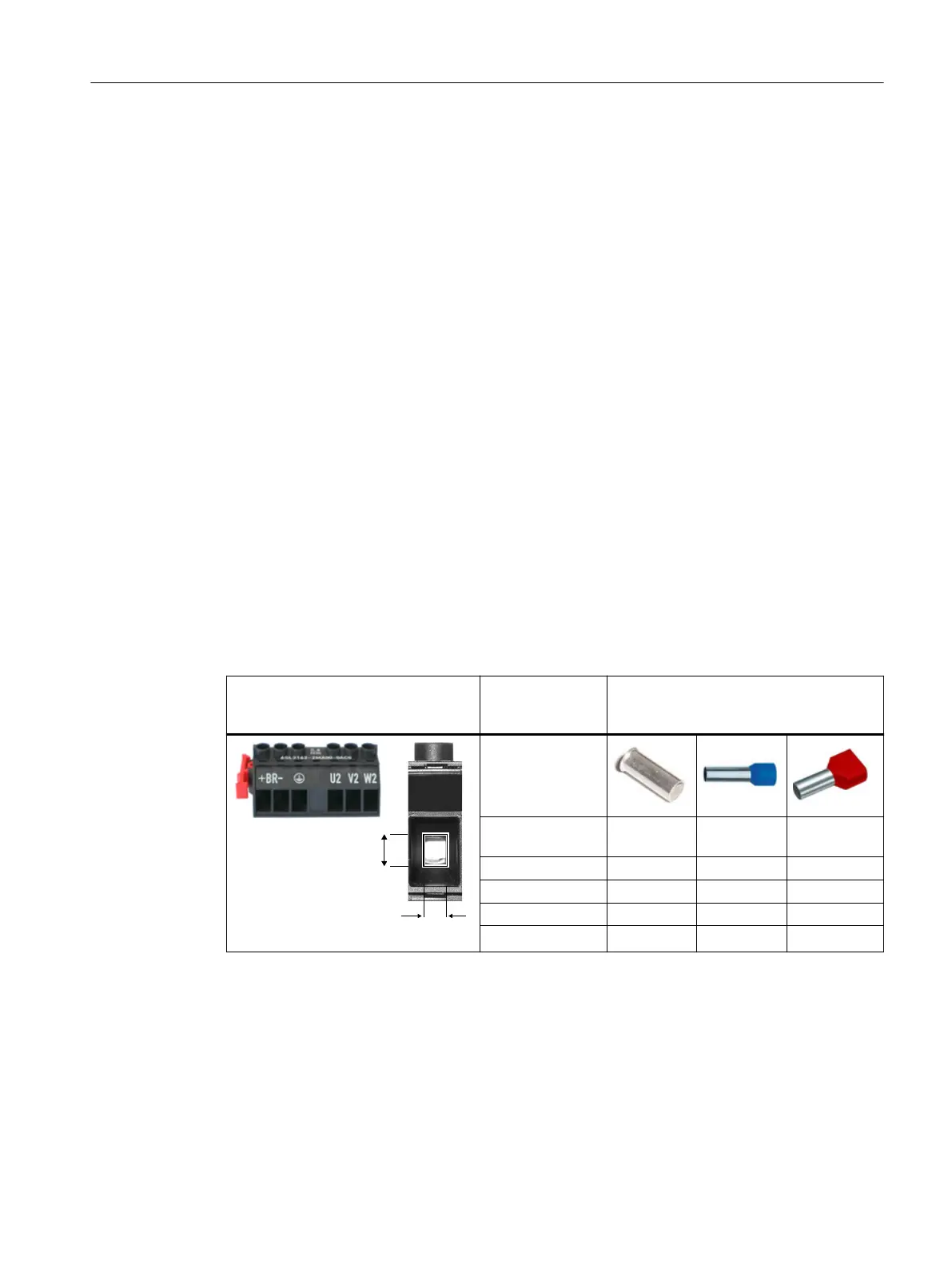

Table 8-14 Connection plug with screw terminal (6SL3162-2MA00-0AC0)

Dimensions of the terminal openings Permissible con‐

ductor cross-sec‐

tions

End sleeve

PPLQ

PPLQ

0.75mm

2

(AWG19)

✓ ✓ ✓

1.5 mm

2

(AWG 16) ✓ ✓ ✓

2.5 mm

2

(AWG 14) ✓ ✓ ✓

4mm

2

(AWG 12) ✓

1)

✓

1)

✓

1)

6 mm

2

(AWG 10) ✓

1)

✓

1)

Not possible

1)

When crimped, conductor end sleeves must not exceed the maximum dimensions of 3.6 x 3.2mm

(0.14x0.13in).

Motor Modules

8.3Motor Modules 3 ... 30 A and 2x3 ... 2x18 A

Booksize power units

Equipment Manual, 09/2023, A5E53307519B AA 179

Loading...

Loading...