3. Break out the cutouts.

– The cutouts on the lower side of the housing must be broken out for all cable cross-

sections.

– The cutouts at the upper side of the housing may only be broken out for larger cable cross-

sections.

4. Using a socket wrench, size 10, connect the DC link adapter connecting cables to the terminal

studs using M6 nuts. Tightening torque: 6Nm (53lbf in)

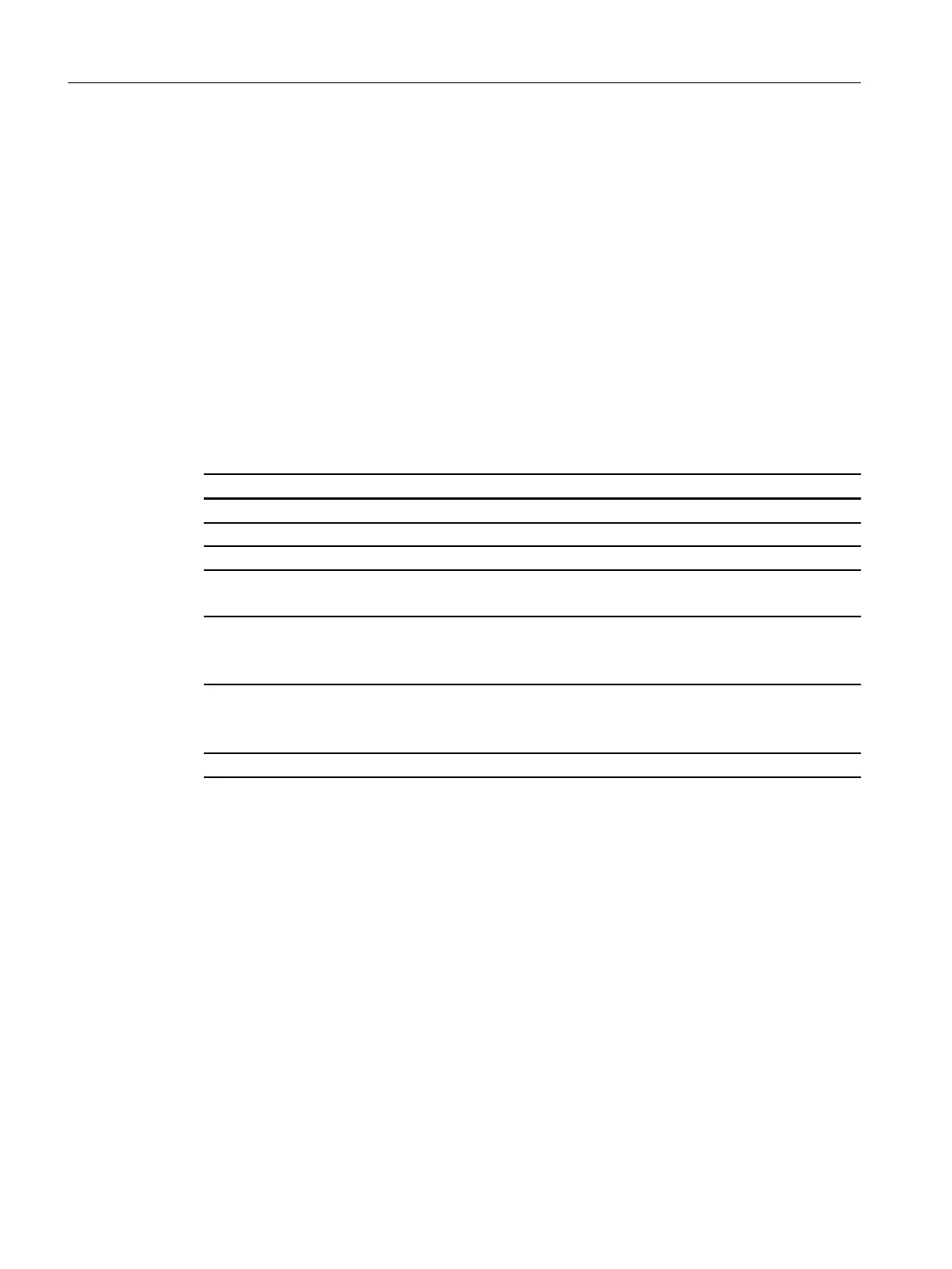

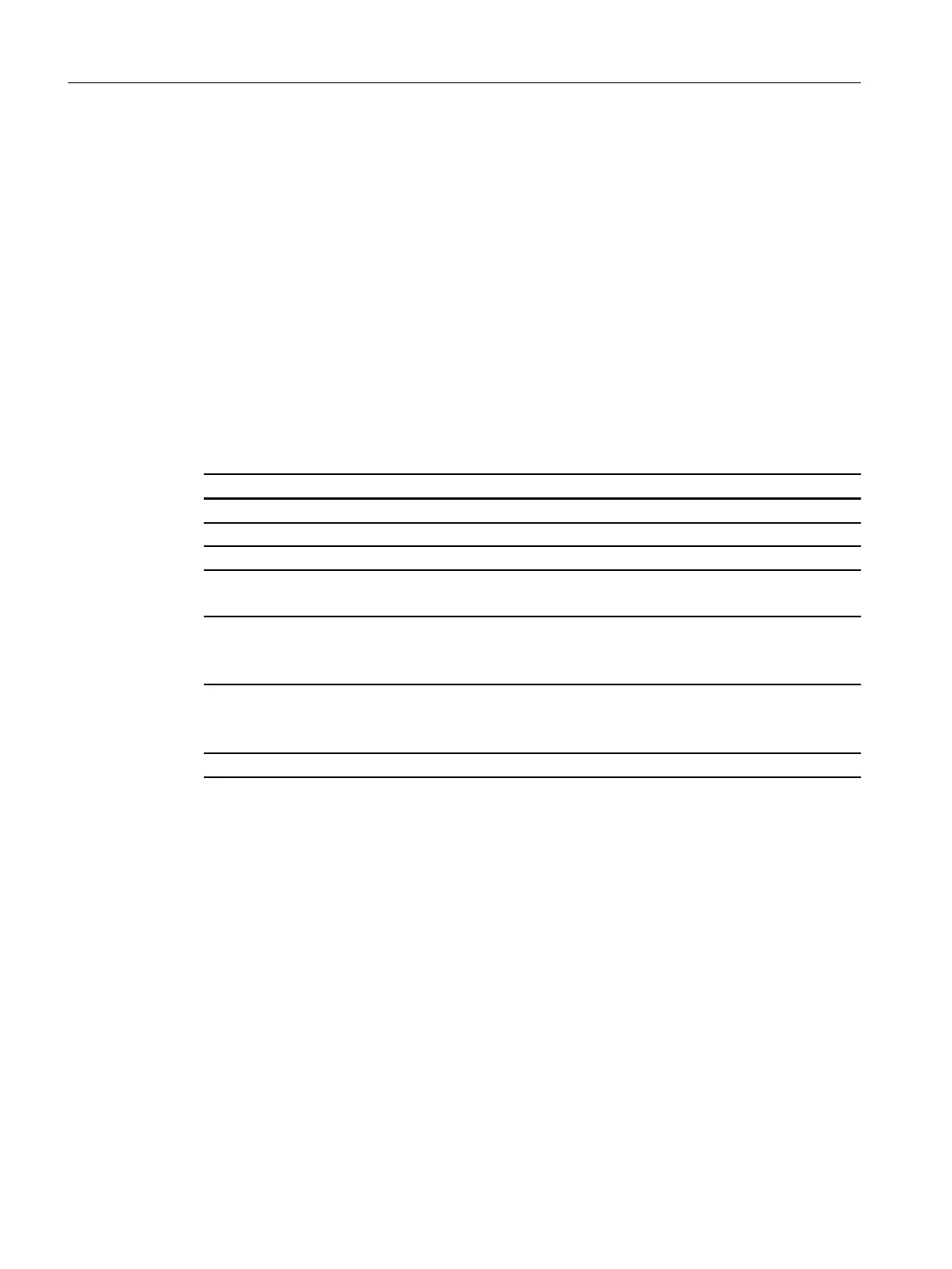

11.4.4.7 Technical data

Technical data

Table 11-9 DC link adapter 72A (6SL3162-2BE00-0AA0)

Feature Unit Value

Supply voltage V 495...720

Continuous current-carrying capacity at 55°C A 72

Maximum ambient temperature °C 55

DC link connection

Tightening torque

Nm (lbfin)

Threaded bolts M6

6(53)

DC link busbars

Fixing screw

Tightening torque

Nm (lbfin)

Torx-slotted screw TX20

1.8(15.9)

DC link adapter

Fixing screw

Tightening torque

Nm (lbfin)

Torx-slotted screw TX10

0.8(7.1)

Weight kg 0.10

11.4.5 DC link adapter 200 A

11.4.5.1 Description

Overview

The 200 A DC link adapter is used to directly supply the DC link voltage. It is preferably used for

supplying an individual component. For a direct infeed, each component is connected to the DC

link separately and the DC link busbars are not connected.

Accessories

11.4DC link adapter

Booksize power units

292 Equipment Manual, 09/2023, A5E53307519B AA

Loading...

Loading...