Only use the temperature sensor input of the Motor Module if the following conditions are

fullled:

• The connected motors are not equipped with an integrated DRIVE-CLiQ interface.

• The temperature values are not acquired via another component (Sensor Module Cabinet,

Sensor Module External, Terminal Module).

Description

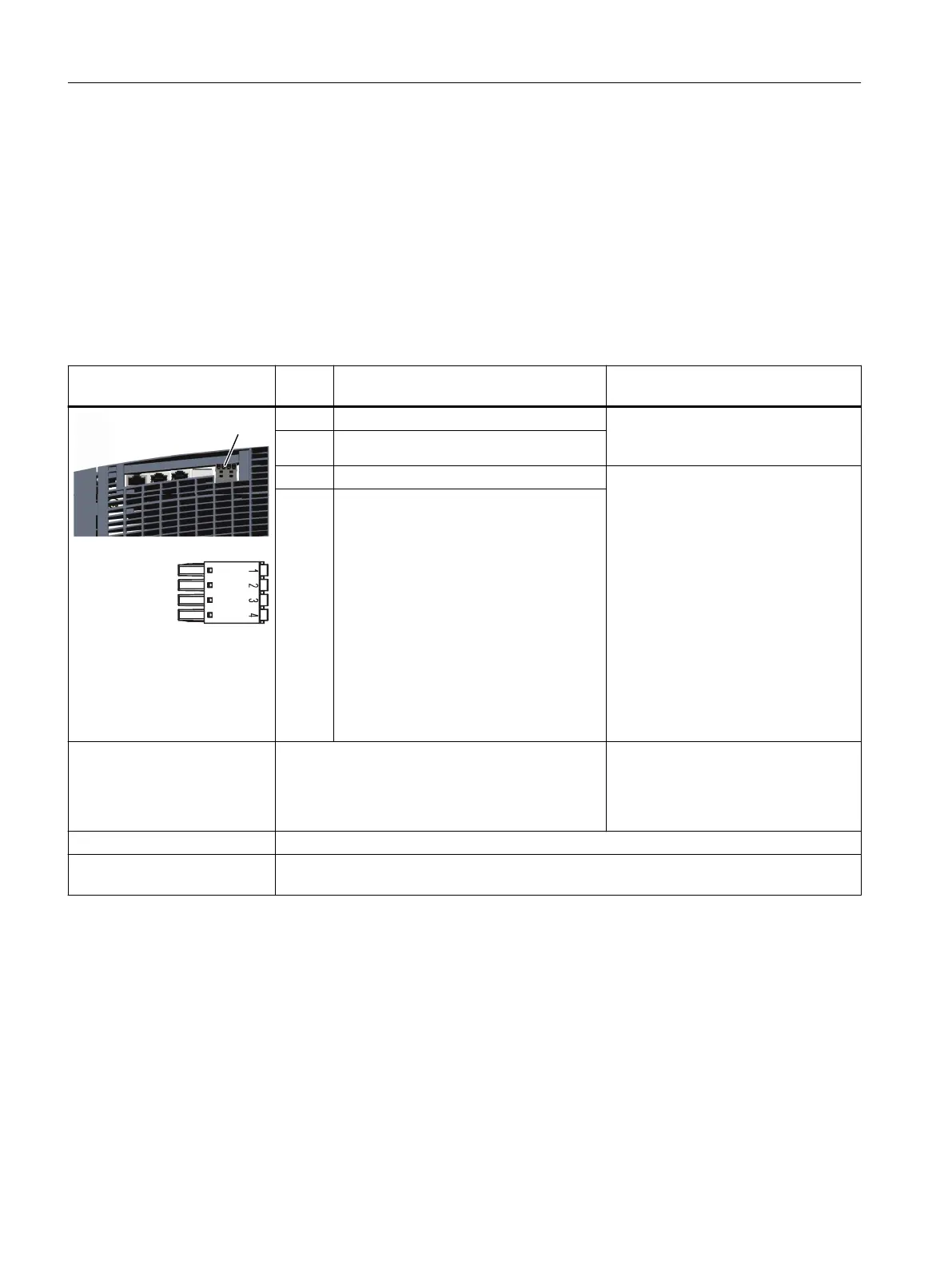

Table 8-3 X21/X22: EP terminal/temperature sensor for Motor Modules 3 ... 200A

X21/X22: EP terminals / tem‐

perature sensor

Termi‐

nal

Designation Technical data

1 + Temp Temperature sensors

1)

: Pt1000 / PTC /

KTY84-130 / bimetallic switch with NC

contact

2 - Temp

3 EP + (Enable Pulses +) Voltage: -3…+30VDC

Electrical isolation: Yes

Input characteristic acc. to

IEC61131-2, type1 and type3

Input voltage (including ripple)

"1" signal: 11…30V

signal "0": -3…+5V

Input current

at 24VDC: 2.5...4mA

at < 1.5 mA: "0" signal reliably detected

Input delay

for "0" → "1": typ.25μs / max.50μs

for "1" → "0": typ.110μs+2μs/m /

max.150μs+4μs/m

4 EP M (Enable Pulses M)

Connectable cable cross-sec‐

tions

Rigid, exible

Flexible, with end sleeve without protective collar

Flexible, with end sleeve with protective collar

AWG / kcmil

0.25...1.5 mm

2

0.25...1.5mm

2 1)

0.25...0.75 mm

2

24…16

Stripped length 8mm (0.31inch)

Screwdriver to release the

terminal

Slotted screwdriver 0.4 x 2.5mm

1)

Accuracy of temperature measurement (temperature sensor, including evaluation):

- Pt1000: ±5°C (Pt1000 tolerance ClassB acc. to EN60751)

- PTC: ±5°C

- KTY: ±7°C

8.3.1.4 X1 - X2 motor and holding brake connection

Overview

The motor and the holding brake are connected to a connection plug (power connector) via the

motor cable. The connection plug is not included in the scope of delivery.

Motor Modules

8.3Motor Modules 3 ... 30 A and 2x3 ... 2x18 A

Booksize power units

156 Equipment Manual, 09/2023, A5E53307519B AA

Loading...

Loading...