4.13.2 Calculating the power loss for Motor Modules in typical applications

Overview

The information on the power losses in the previous chapters are maximum values, which occur

in the most unfavorable case. For typical applications, the losses are lower.

The following applies as typical application:

• Maximum motor cable length, 30m

• 4kHz pulse frequency

• DC link voltage 540V - 600V

Description

Power losses for typical applications can be calculated based on the following formula:

P

V

[W] =a+S

1

•(I

1

+I

2

)+S

2

•(I

1

2

+I

2

2

)

a Electronics losses of the Motor Module

S

1

, S

2

Coecients to calculate power loss

I

1

Current (arithmetic mean value) of the 1st axis

I

2

Current (arithmetic mean value) of the 2nd axis

Overview of required coecients

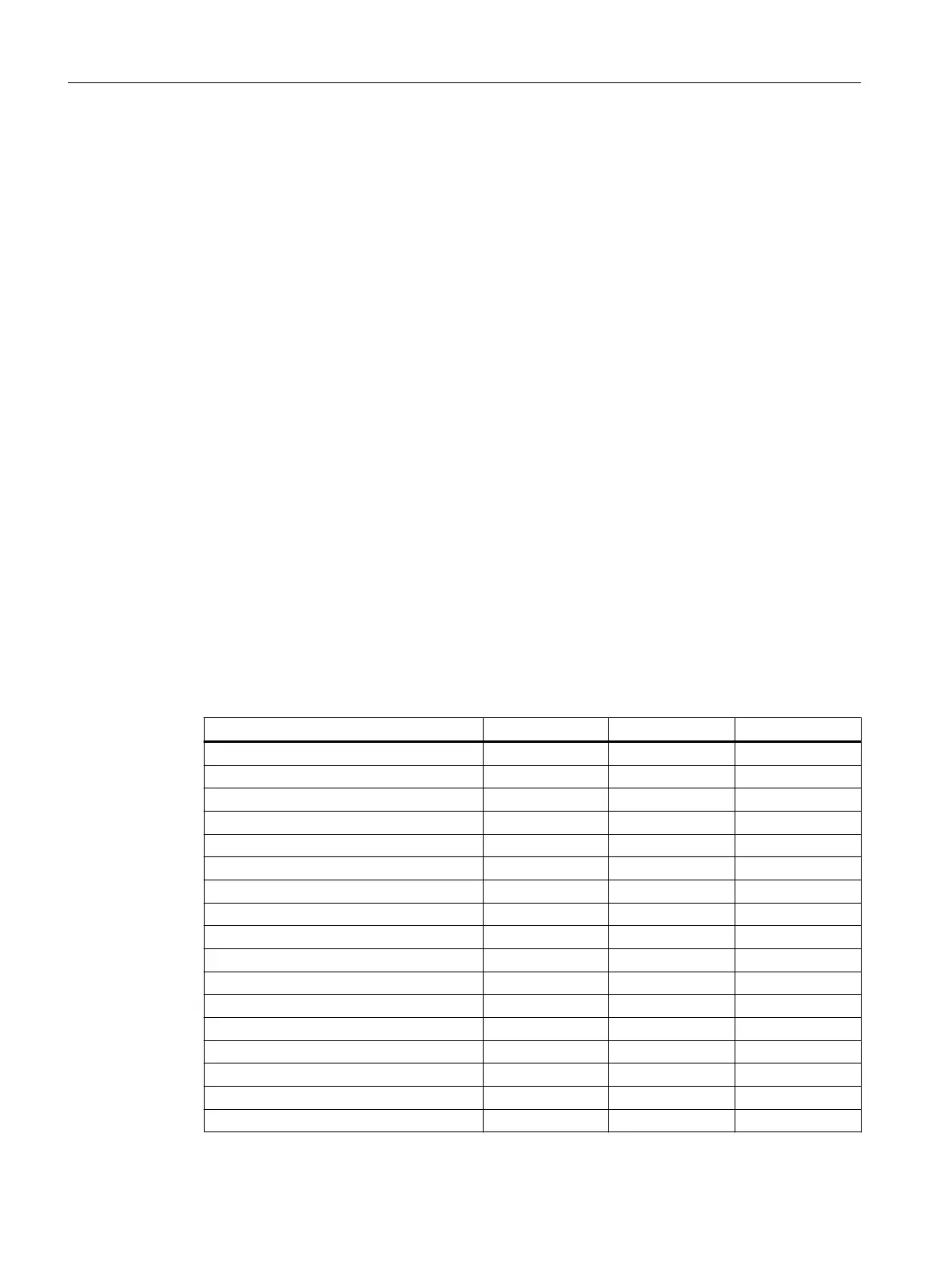

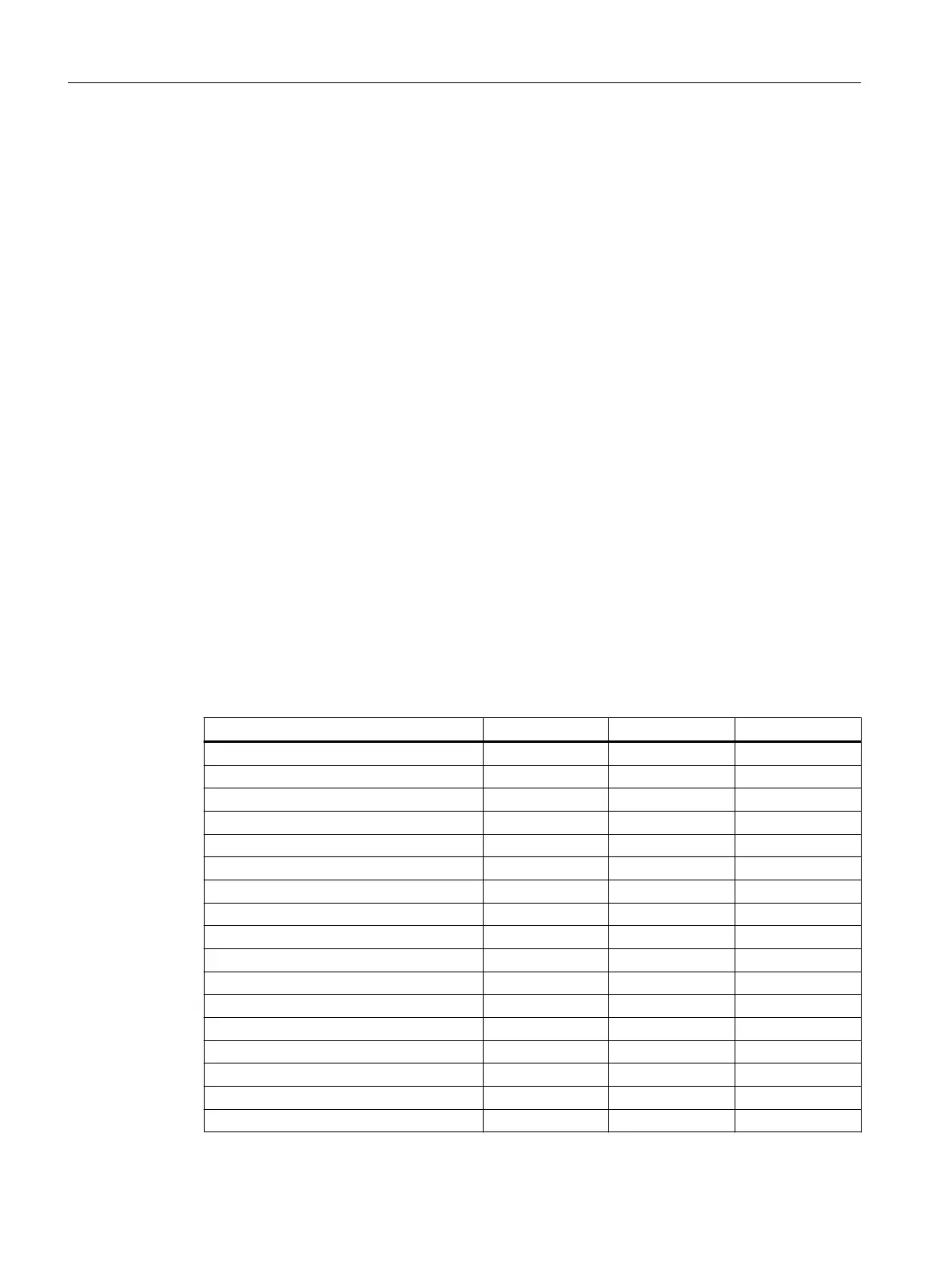

Table 4-17 Coecients to calculate the power loss in the control cabinet for Motor Modules for

typical applications

Motor Module a [W] S

1

[W/A] S

2

[W/A

2

]

Single Motor Module 3A 17 3.29 0.205

Single Motor Module 5A 18 3.29 0.205

Single Motor Module 9A 19 3.29 0.205

Single Motor Module 18A 24 3.29 0.205

Single Motor Module 24A 24 3.50 0.140

Single Motor Module 30A 18 4.71 0.113

Single Motor Module 30A (slim) 29 4.71 0.113

Single Motor Module 45A 24 4.40 0.060

Single Motor Module 60A 24 4.40 0.055

Single Motor Module 85A 125 6.01 0.017

Single Motor Module 132A 125 6.01 0.017

Single Motor Module 200A 125 6.01 0.017

Double Motor Module 2x3A 24 5.20 0.200

Double Motor Module 2x5A 26 5.20 0.200

Double Motor Module 2x9A 26 5.18 0.247

Double Motor Module 2x18A 23 5.57 0.091

Double Motor Module 2x18A (slim) 31 5.57 0.091

Application planning

4.13Power losses

Booksize power units

62 Equipment Manual, 09/2023, A5E53307519B AA

Loading...

Loading...